It's been seven years since Jani Ponkko, nicknamed Japala, did his first work with engraving and acrylic lighting. Then it was a simple mouse pad. Many new things have been discovered in modding over the years. The technique has become more perfect, and modders have accumulated a lot of experience. But as then, today one sheet of acrylic for engraving is most often used. But you can work with several. This can open up new possibilities: multicolored lighting, believable image of 3D models or even animation creation. Jani Poncco will show what can be done with several layers of acrylic, dremel and LEDs.

As the name implies, the technology of multilayer design consists of two or more layers of acrylic. Each layer can have its own pattern and color. The result will be impressive.

For the first time about the multilayered image by engraving on acrylic Japala has started talking in 2002. Then he made a trial project - the silhouette of an anime-style girl with a flashing red ball. The girl herself was engraved on one layer, the ball on the other.

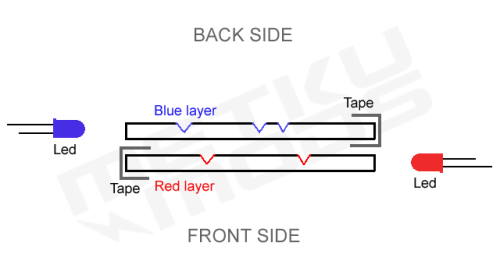

First, you need to understand the very principle of highlighting engraving on acrylic. Engraving is a series of thin grooves in acrylic. To make them more visible, they are highlighted. For this purpose, high-intensity LEDs are usually used. The place of engraving is scattered by light, and it reaches the viewer. With multi-layered animation, first one layer is highlighted, then the second, third and so on. The result is similar to animated neon signs.

Japala does the engraving on the back of the acryl sheet. This improves the diffusion of light and makes the picture brighter. Just remember that the image needs to be done in the mirror image. The modder himself admits that he sometimes forgets this simple truth. This is not so important with an arbitrary picture, but the sheets with the text can be discarded.

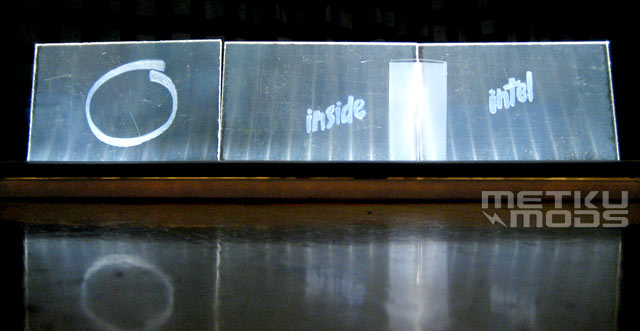

For the animation, Jani chose the Intel logo. There are reasons for that. This is the first design, consisting of three elements, which came to his mind. In addition, images on different layers are not superimposed on each other, which makes the task easier for the first time.

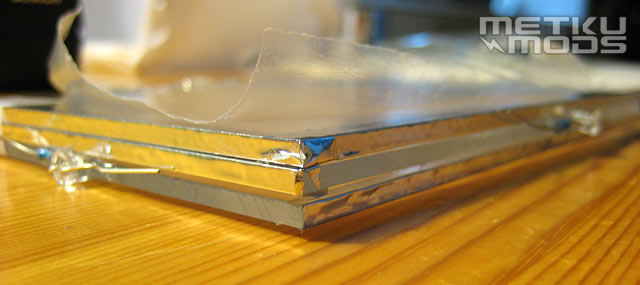

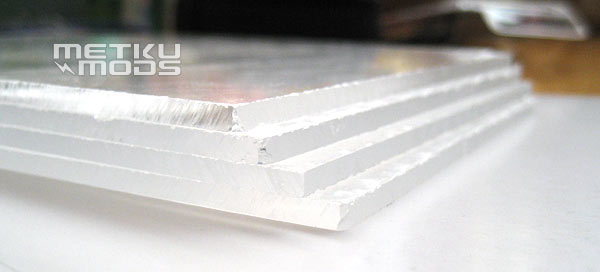

After a short session with a dremel, all three layers were ready. In the photographs, the acrylic sheets seem a little muddy. Do not worry, just the protective film has not yet been removed.

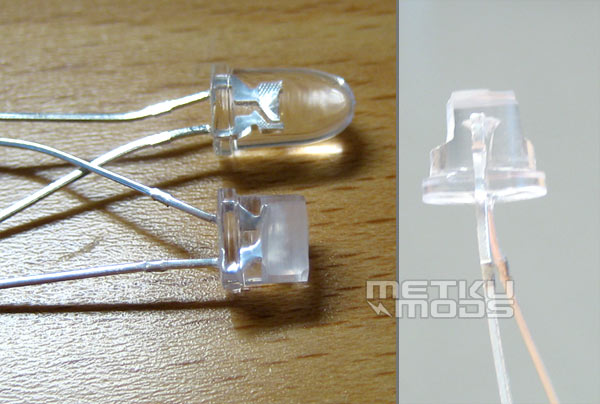

Used LEDs have a thickness of 5 mm. The thickness of acrylic sheets is only 3 mm. So I had to work on them a little bit. Now they have become shorter and more compact, which slightly simplified their installation. But if in the store are available 3-mm LEDs, it is better still to buy them immediately.

Then Japala made a pair of LED + resistor. Epoxy adhesive can damage acrylic, so ordinary glue was used.

For a sheet with the word "Intel", one LED was used, as for the "Inside" layer. But to illuminate the image of the oval, two LEDs are placed, located on opposite sides.

The opposite edges of the acrylic sheets were wrapped in aluminum tape. It has a mirror effect, so the beam of light will be reflected until it comes out through the engraving line. In addition, this will create a light insulation between the layers.

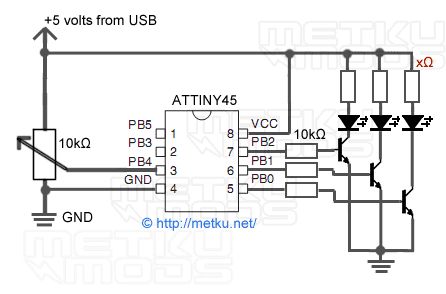

Japala used the ATtiny4 chip from Atmel. It includes several LEDs in turn. But this thing modder used only for verification. It was decided to create its own scheme.

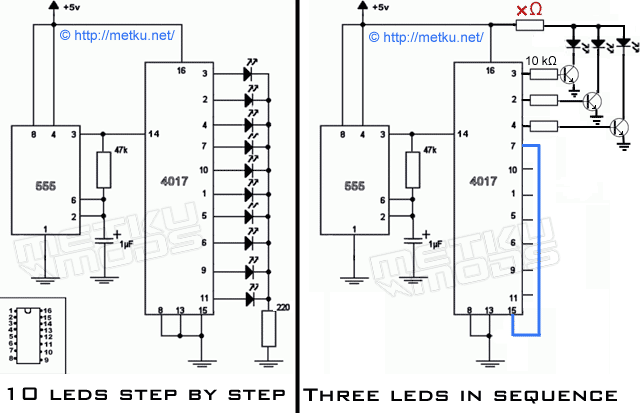

Previously, for the organization of alternate switching of LEDs, the enthusiast used the scheme shown on the left. The switching speed of the LEDs is controlled by the 555. In addition, if you replace the 47 kΩ resistor with a potentiometer, you can manually change the frequency of the switch.

But for the current needs it is more convenient to use the right schema. At the heart of it is almost the same, but the outputs are connected in addition to a bipolar transistor such as NPN. This allows you to control a large number of LEDs. Note that the blue wire is from output 7 to 15. Connector 15 in this circuit is reset, when a signal is received, it supplies power to the first LED. In this case, the number of illuminated layers can be varied. If you move the blue wire to the output at number 10, and to connect one more LED to 7, you will get 4 layers already.

This scheme was originally developed for other purposes - the regulation of tricolor illumination. But programmatically changing the pulse width modulation allowed to quickly prepare the device for current tasks. The chip contains a resonator at 8 MHz and three separate channels. The regulator controls the speed of switching.

It was possible to use the scheme of alternate inclusion of each layer. But Jani did not go the easy way. He did so that at the end all three layers light up for a moment and simultaneously go out.

Three joined layers were 9 mm thick.

The new Dremel 400 was used to create a wooden frame. Usually, the modder does not spend so much time on trial versions, but he decided to finish this thing to the end.

All layers are collected. The first is "Intel", then "Inside". Leaf with an oval is the last. The backlight is turned on in the same order. In the design used, the sequence does not play an important role, since there are no overlapping engraving lines.

In this case, the author did not use devices to scatter light. You can take a piece of white paper or matte acrylic. This will spread the light a little better. But if you go through sandpaper on the surface of the LED and acrylic sheet, then this method will not give results. The glue will eventually smooth both surfaces.

This could be completed, but Japala went even further

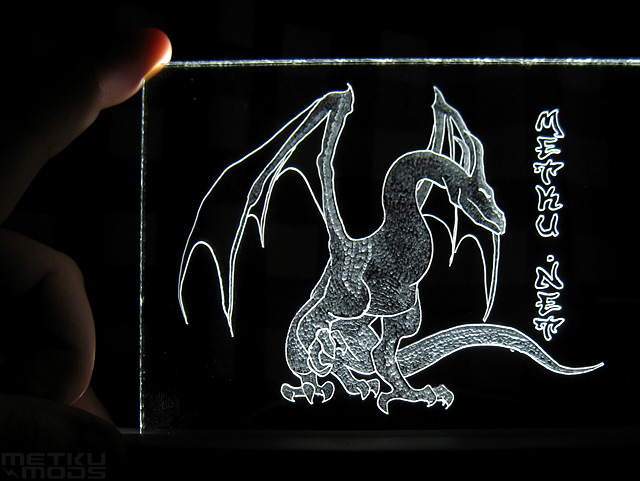

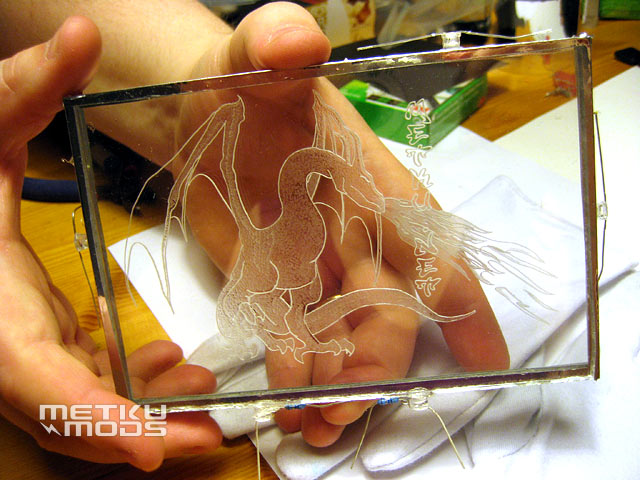

The drawing of the dragon was created during the testing of a new instrument - Dremel 290-05.

In this work, 4 layers of acrylic are already used. The first one shows the dragon himself. It is highlighted in white. Then there are three layers of flame: from smaller to larger. All of them are red and turn on in turn.

Jani Ponkko admits that he himself is surprised by the effect of the fire-breathing dragon. Only three layers of flame, animation and competent illumination can make a real miracle.

Modder perfectly coped with all the stages of production of multi-layer engraving with animated illumination. He paid particular attention to cleanliness. Even the slightest speck of dust between the layers of acrylic or fingerprints can significantly spoil the overall impression of the picture. But do not use alcohol-containing products when cleaning acrylic, they can damage it. In addition, it is necessary to keep the protective film as long as possible.

In the end, it should be noted that the technology of animated multi-layer illumination made from a rather simple picture an impressive picture. Is it worth talking about new spaces for imagination in the field of application of this device.

Comments

Commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.