Computer MODODING.

Computers in our time are becoming an integral part of our lives, becoming our helpers and friends. Computer cases are mostly of the same type and monotomous. And everyone wants to bring a zest to their computer, make it unique. These are the factors that push people to create their masterpieces, and for some, modding is the goal of life.

To create masterpieces you do not have to be a professional. And in proof of this, I present to you Max Erldasson.

Max Erlandsson (Max Erlandsson) - beginning modder from Sweden. According to his first work, one can already judge his talent - it is so impressive.

Max is a big fan of science fiction. Therefore, initially the mod was conceived in the style of an atomic reactor. The name came by itself - Cold Alloy.

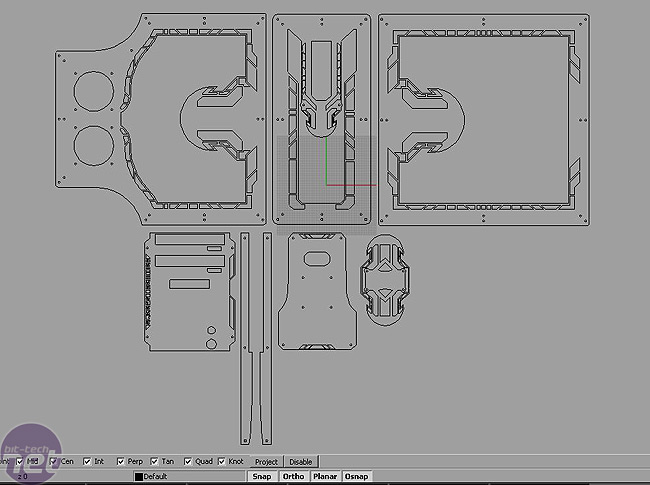

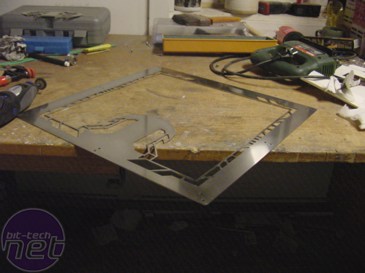

In the project, the modder decided to use a large number of metal parts and Plexiglas. To facilitate the process of manufacturing panels of the desired shape, it was decided to use laser cutting technology. This allowed us to save not only time, but also strength. Max decided to use 2.5 mm metal plates. To develop the shape of the panels, the design package Rhinoceros 3D 3.0 was used.

The victim of the modder was the case Antec SLK3000B. In its original form, it looks too boring. But this SleepStreamer decided to put an end to.

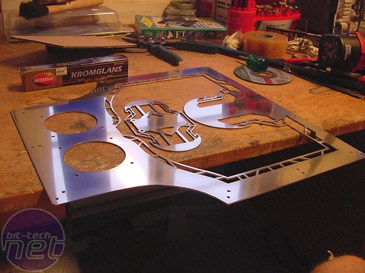

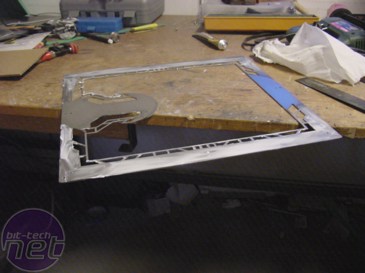

After the return of the plates from the laser cutting shop, it was possible to proceed to the first stage of the modding. The panels look perfect, except for small blots on some parts surfaces. But even this can be easily corrected.

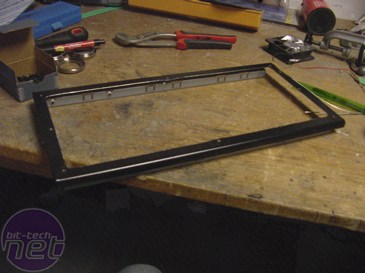

For tight fitting of metal panels to the side walls of the body it was necessary to cut down the standard grilles of the ventilation holes in the right-hand cover of the case.

With the help of the engraving tool, an additional ornament was applied to the standard side walls of the body. As you can see, the black paint was wiped off, and bare steel was exposed.

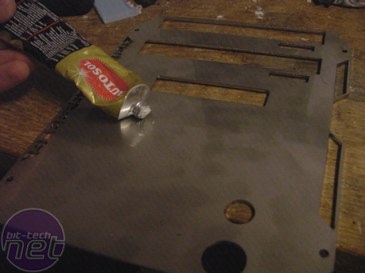

At the end of work with the right side, the cut panel was polished with the help of the automobile "Autosalt" means. It is well suited for this type of metal and it clears the surface of small defects with great care.

After that the case was dismantled for the beginning of the next part of the work.

The use of dremel to cut out large parts of the metal took Max a very long time, he said, it took forever. So he decided to act differently. For these purposes, the modder used another tool. At first, perforations were drilled with a drill, and then a piece of metal was squeezed out. Thus the process ended much faster. For cutting in the plexiglass holes for the fan, a special tool was used to make round holes.

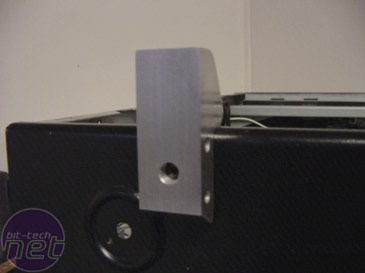

Rivets were used to attach the panel cut by the laser to the upper side of the housing.

The result of the application of Autosalt can be seen on the following two photos.

With the help of the grinder, the invented logo was engraved on the left-hand cover of the case.

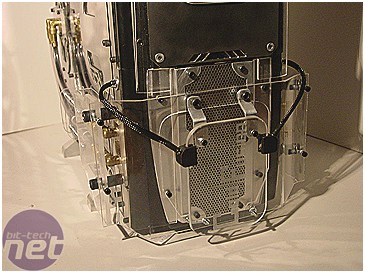

It's time to install a water cooling system. This time it will perform two functions at once: the main one is the cooling of the system components, as well as the aesthetic - the completion of the industrial appearance of the enclosure.

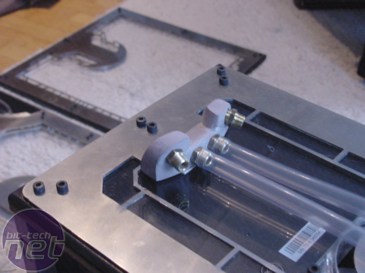

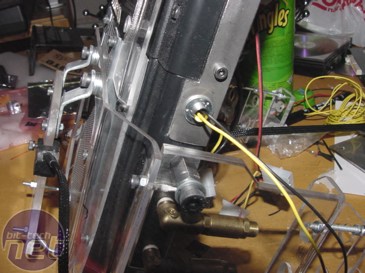

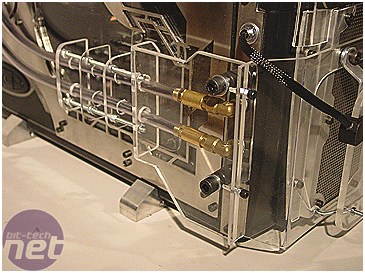

These are the adapters for tubes Max used throughout the body.

To mount these adapters, a special plastic block was made. It can be inserted four tubes. It took a lot of time and energy to create it.

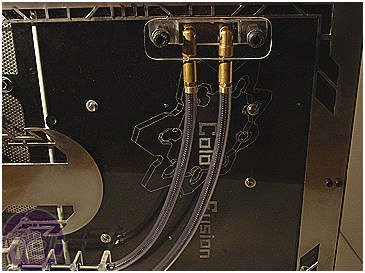

Two tubes SleepStreamer decided to bring out. To fix them, the modder made several small panels of plexiglas. One of them was fixed on the upper side of the case. Then, two parallel tubes were conducted along the top. This will give the body even more futurism.

The internal compartments for hard drives were too boring because of their gray color and uninteresting shape. Max corrected the situation with the help of pieces of plexiglas, painted in black. Waiting for them to dry completely was a big obstacle.

In order not to lose time, the modder started on the left side of the case. The iron lid was replaced with acrylic. Something particularly complicated here was not, everything went according to plan. Further, this side will be decorated with the logo itself.

After drying the acrylic panels, they were attached to the proper places inside the case.

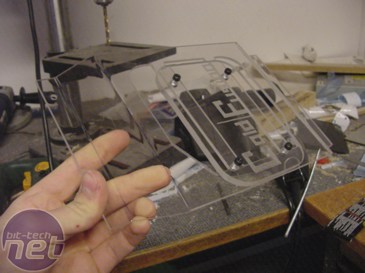

SleepStreamer conceived to hide a small section of the motherboard and video card behind the panel of Plexiglas.

So, it's time to convert the front panel of the case. For this, a metal panel and painted pieces of plexiglas were prepared. They change the upper half of the front of the body.

First, an engraving was made from Plexiglas. Then the black plugs of the optical drive bays.

Max used pieces of metal to emphasize the urban style. In the plexiglass panels, small holes have been made for fixing the tubes of the water cooling system.

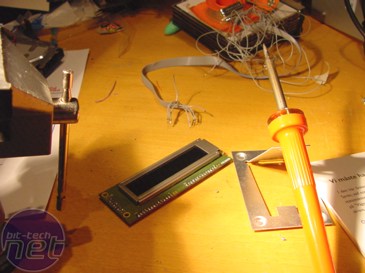

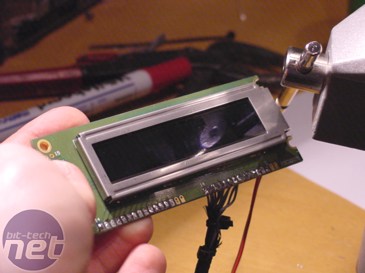

On the front panel the modder decided to shelter a small LCD-display. It can display the main indications of the system, such as temperature data, or simply certain inscriptions.

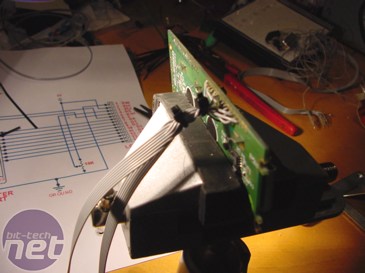

It took a lot of time and effort to connect all the necessary wires to the display board reliably and in the necessary order.

The prepared display does not look stunning on the table, but in the case it should make a good impression.

The plastic on the front side of the hull required an urgent reorganization. To do this, the modder used some metal.

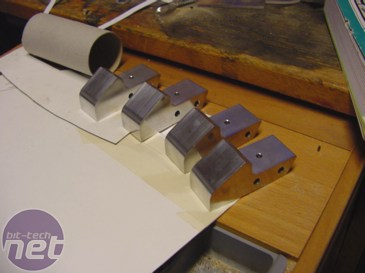

Ventilation holes in the lower part of the front did not correspond to the project's theme in any way. To disguise them, Max bought a perforated aluminum panel. He covered the ventilation holes. To support this grill, two symmetrical supports were made for both sides. The template you can find on the photo on the left, and on the right is the final result.

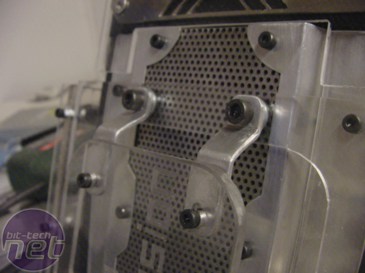

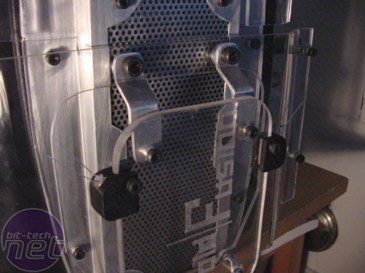

To install the logo at some distance from the body of the modder made two aluminum staples. But here he faced the problem of installing the remaining acrylic panels. Max had to poke a little with the size of pieces of Plexiglas, so that everything conceived turned into reality.

Then the wires of the LEDs were placed in an aesthetic braid, perfectly complementing the style of the case.

The last step was the creation of the base of the hull. It should be small. To begin with, the standard rubber feet have been removed.

Their place was taken by metal ones. These legs are very large and fit perfectly in the overall picture. They were bolted directly to the bottom of the hull. That's how it looks.

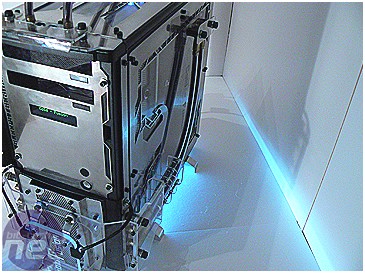

After all the actions the project has not been fully completed. The fact is that the modder spent a decent amount to buy computer components, modding parts, laser cutting, that he did not have enough money to purchase a good water cooling system. So, soon, Max plans to bring the conceived to the logical end. In the meantime, you can admire the result.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.