Ways of drawing convex and concave inscriptions and drawings on metal

Ways of drawing convex and concave inscriptions and drawings on metal

Labels on metal plates, making scales and simply drawings on a metal surface can be made by etching (chemical milling, engraving).

Chemical milling can also be used to reduce the thickness of the metal walls of parts, increase the diameter of the holes or reduce the diameter of the rods, bolts and pins.

Making an inscription or a picture on an aluminum panel (convex image - chemical milling). The surface of the metal is polished, washed with water and dried. Then it is labeled or patterned with any alcohol varnish, after which the panel is etched in alkali. Metal, protected by varnish, alkali, is not etched, and the inscriptions are convex.

Aluminum and its alloys are best etched with 10-15% solution of caustic soda.

It should be remembered that such milling is very slow.

When the solution is heated to 60-80 ° C in 20 minutes, a metal can dissolve

After etching, the panel is thoroughly washed with water and polished.

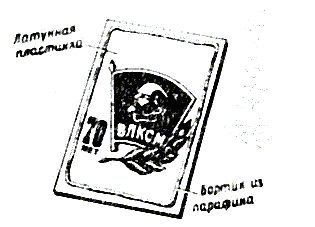

Making an inscription or a picture on a brass panel (depth image - chemical engraving). The metal panel is polished, washed with water and dried. Then it is heated to a temperature of 60-70 ° C and covered with a layer of paraffin, which, melting, flows smoothly over the entire surface. On the paraffin-covered panel, an inscription or figure is translated through a carbon paper. Further, with the tip of the needle and the tip of the penknife, carefully remove the paraffin layer from the inscription or drawing, which must be deepened (etched).

At the edges of the panel of softened paraffin, make a bead 8-10 mm high ( Fig. ). After that, 50% nitric acid solution is poured onto the panel, which dissolves (etches) the metal in paraffin-free places, forming an inscription or a picture. By tilting the panel, you can see whether the inscription or the drawing has been etched out enough.

Attention! The panel can be etched with nitric acid only under the hood or outdoors.

When the etching is finished, the solution is poured and the panel is thoroughly washed. The remaining paraffin is easily removed by placing the panel in hot water heated to a temperature of 90 ° C and wiping it with a dry rag with chalk. To protect the panel from oxidation, it is covered with a clear varnish.

Pickling solutions for chemical milling

Metal |

Pickling solution |

Brass and bronze |

50% acid solution |

Aluminum and duralumin |

10-15% solution of caustic soda |

Copper |

70% solution of ferric chloride with the addition of 0.3-0.35% hydrochloric acid |

Zinc |

8-12% alcohol solution of hydrochloric acid |

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.