| section Home

Production, Amateur Radio amateur Model aircraft, rocket- Useful, entertaining |

Stealth master

Electronics Physics Technologies invention |

space Mystery

Earth Mysteries Secrets of the Ocean Stealth section Map |

|

| Use of material is permitted for reference (for websites - hyperlinks) | |||

Navigation: => |

Home / Forum Index / Contents sub / |

|

Low-cost SPEED DRY electrotechnology

Porous materials such as wood

![]()

Dudyshev Valery, Russia, Samara

Samara Technical University

(Application for invention registration FIPS- №2005002658)

The invention relates to devices remove moisture from porous materials, such as wood.

The technical result of this utility model is to improve the drying device of porous material, such as wood.

Said technical result is achieved by that in the known device, comprising a drying chamber, a moisture removal device of porous material in the form of an electrical device comprising two electrodes and a voltage source and a moisture removal device from the drying chamber, the moisture removing device of porous material is in the form controlled electroosmotic pump, for example, high capillary type, and as this pump capillaries used pores drained capillary material, then the dried material, with the electroosmotic pump consists of adjustable amplitude and frequency of the high-voltage converter constant sign voltages, for example in the form of an inductive pulse oscillator type voltage blocking oscillator, resonant high-voltage Tesla transformer, high-voltage electrostatic generator Van de Graaff and goals of its implementation, of the dried material, and two or more electrodes are electrically connected to the output, for example, the positive and negative potentials of the high-voltage converter, and the pusher moisture and pulls moisture electrically charged electrodes are dimensioned and the squares are equal to or larger sizes, and the areas, such as the end faces to drying the porous material, wherein one of the electrodes, for example, a positively charged electrode (s) is firmly attached (s) to one of surfaces of the dried material, for example, an end, and a negatively charged electrode (s) and tightly or with a gap attached (ies) to the opposite, for example, the end surface of the dried material, wherein one or more of electrotechnology pump electrode puller moisture electrode, e.g. negatively charged electrode (dy) comprises (al) adsorbing device and evacuation of vaporized by the electric field, for example, cold steam, and (or) a liquid of the dried material, and the adsorbing device and the fluid evacuation extracting electrode wicking comprises a capillary material, a perforated membrane, and pressing device liquid, such as sample catcher with regulator vibration amplitude and frequency of diaphragm vibrations being puller moisture electrode comprises a dense crimping dried material device, and functionally and structurally combined with a vacuum device and placed, for example, below the dried material, wherein the vacuum device comprises a vacuum pump, the tank for collecting liquid, and a check valve connected to the atmosphere, and a pulling moisture electrode is made of porous material, wherein the device is provided with one or more heat generators local or distributed heating the dried material, for example, the generator (s) directed microwave radiation, the heating (E) device (s) of the electrothermal heating, gas burners placed locally or throughout the volume of the chamber drying used in the process of drying material separately, in various combinations, and (or) simultaneously, as the device of the local thermal heating of drained materials used microwave heat source, a radiator, such as directional placed in a drying zone one of the surfaces of the material, for example, in the end part of timber, and structurally combined with the pusher moisture electrode, and ejecting moisture electrode, for example, the positive electrode of the electroosmotic pump is structurally combined with heating ( E) the device (s), for example, electrothermal heating, for example, the ends of wood, wherein the heating device includes, for example, carbon-fiber activated material further activated material, and a source of thermal energy, for example, combined with the electrode electroosmotic pump as an electric heater, electrically connected to an additional adjustable voltage source with a temperature controller and power, the activated material with the heating element is designed as a web which is covered, for example, end portions, parts, and (or) the entire desiccant material, the device completed the centrifuge for rotating dried material and primary liquid pressed from the porous material by centrifugal forces, and be dried capillary material, such as timber (sawn timber) is arranged in the drying chamber capillaries vertically, the pusher moisture electrode with a heating device and the dense crimping drained material reinforced with top dried material, and a puller moisture electrode device adsorption and fluid evacuation device tight crimp dried material, sample catcher vacuum device and containers for the collection of fluid strengthened bottom-dried material, and on top of the dried material can be placed a container of impregnating a specific purpose liquid connected to the pusher electrode, ensuring its continuous or cyclic transfer (suction) in the material, such as electroosmosis and by gravity, for example by perforation, this device completed device cyclical movement of one or more electrodes of the electroosmotic pump equipped adsorbents moisture along the surfaces of the dried material, for example, according to the program, ensuring high quality of the dried material at a given intensity very drying, for example, the initially wet desiccant material, such as wet bricks, paper, concrete products moist bulk materials and other, placed movable relative to the electrodes electrotechnology pump, for example, are placed flat fixed electrodes with a minimum gap relative each other, for example, drained material placed on the movable non-conductive tray, such as on a conveyor belt, the top and bottom and (or) from the sides of the rolling pallet, the electrodes of length and width, for example equal to the length of the tape, and the width of the pallet, for example, the working part of the belt conveyor ,. attached to heteronymic high-voltage electric potentials of the voltage converter, or the material is placed directly on the electrically conductive movable tray, for example, an electrically conductive conveyor belt with placed thereon adsorption conductive material structurally combined with one of the electrodes, and the second and other electrodes in the form of electrically conductive (their) plane (s) placed on them (or) from the sides of the conveyor belt, at a distance sufficient to prevent electrical breakdown of electrodes attached to heteronymic electric potentials, and remove moisture from porous materials, the device may be completed device pressed wet adsorption belt of transporter, aligned, for example, with its rollers and the receiving device - a container for the collection of the removed materials and squeezed water, and contains, for example, three electrodes, and be dried capillary material, such as wood, that serves in the chamber drying between two or more mutually movable electrodes znakopostojannom electric field with the direction of the electric field preferentially along the capillaries, wherein the two planar electrodes may be tightly mechanically coupled to the ends of the capillary material, such as mechanical slicing wood, electrical interconnection them to heteronymic electric potentials of the high voltage of constant sign of the voltage converter, and a third electrode, for example, circular, covering drained the capillary material, such as a tree trunk may be movable with the movement of it along these capillaries, for example, with its original spatial placement near an electrode with an opposite electrical potential, and its subsequent disposable or cyclic displacement, minimum clearance along the capillary bore, for example, between the positively and negatively charged electrodes, electrically joined to the output of the voltage converter, the device being supplemented intensifier drying, for example, a container of easy boiling liquid tightly connected to the pusher electrode, wherein one of the two electroosmotic pump electrodes is made porous and is immersed, for example, an end surface of the dried material in the readily boiling liquid, such as acetone, which by means of electroosmosis is introduced into the capillaries of the material, on the opposite side of the moisture removal, the apparatus is provided and both local heater of low-boiling liquids in the capillaries of the material, for heating it to boiling, a subsequent displacement formed by vapor of the fluid from the drained moisture material, wherein as fluid introduced into the wood or other porous material may be used for example, antiseptic solution, fireproofing solution timber staining solution and so forth., wherein the device has an interconnected, for example via a processor control system comprising a drying device controls, for example, to regulate the drying rate, for example, control of material heating intensity regulator productivity electroosmotic pump, such as a regulator of the electric field between the electrodes, and ( or) the frequency of the electric field pulses, control the frequency and amplitude of the sound vibrations, control the degree of vacuum of the working area, humidity sensors, positioned in the volume of the dried material, and and and the device (s) of the switching circuits in the process and at the end of drying and programmable device of porous drying for a given program material, the moisture removing device is supplemented with a porous adsorbent, attached to the working surface of one or more electrodes, and (or) enveloping all be dried porous material, wherein the limiting moisture capacity of the porous adsorbent is chosen from certain conditions, for example, should be sufficient to accommodate all moisture from the dehumidified electroosmosis, porous material, which is complemented device stacking drying material, such as wood, and the device its sealing, which is formed of an elastic material, such as thick polyethylene, synthetic leather, for example, folding, for example in the form of bellows, clothe on the pile of wood and fastened to one end of the stack with a drying material, such as a vacuum ring which is simultaneously the pulling electrode electroosmotic installation, the apparatus stacking can be constructively combined with the other elements of the device of drying, such as the electrodes of the electroosmotic pump adsorbent and heating elements, the apparatus may be designed as a mobile container, for example on a vehicle, and can be supplemented with a device sealed package dried materials such as lumber.

A device for removing moisture from the porous materials

The invention relates to devices remove moisture from porous materials, such as wood.

The closest device of the same purpose in the stated utility model by a set of attributes is a moisture removing device of porous materials such as wood, comprising a drying chamber, a moisture removal device of porous material in the form of an electrical device comprising two electrodes and a voltage source and a moisture removal device from the drying chamber - a prototype - RF patent №2115870.

With all the advantages of the prototype, the existing moisture removal device of porous materials such as wood does not provide sufficient intensity to be dried the drying material, such as wood, and requires a large electric power consumption at creating electrical discharges.

The aim of invention is to increase efficiency and the intensity of the drying process of the porous material, such as wood.

The technical result of this utility model is to improve the drying device of porous material, such as wood.

Said technical result is achieved by that in the known device, comprising a drying chamber, a moisture removal device of porous material in the form of an electrical device comprising two electrodes and a voltage source and the device remove the moisture from the drying chamber, the moisture removing device of porous material is in the form controlled electroosmotic pump, for example, high capillary type, and as this pump capillaries used pores drained capillary material, then the dried material, with the electroosmotic pump consists of adjustable amplitude and frequency of the high-voltage converter constant sign voltages, for example in the form of an inductive pulse oscillator type voltage blocking oscillator, resonant high-voltage Tesla transformer, high-voltage electrostatic generator Van de Graaff and goals of its implementation, of the dried material, and two or more electrodes are electrically connected to the output, for example, the positive and negative potentials of the high-voltage converter, and the pusher moisture and pulls moisture electrically charged electrodes are dimensioned and the squares are equal to or larger sizes, and the areas, such as the end faces to drying the porous material, wherein one of the electrodes, for example, a positively charged electrode (s) is firmly attached (s) to one of surfaces of the dried material, for example, an end, and a negatively charged electrode (s) and tightly or with a gap connected (ies) to the opposite, for example, the end surface of the dried material, wherein one or more of the electrodes electrotechnology pump draws moisture electrode, e.g. negatively charged electrode (dy) comprises (al) adsorbing device and evacuation of vaporized by the electric field, for example, cold steam, and (or) a liquid of the dried material, and the adsorbing device and the fluid evacuation extracting electrode wicking comprises a capillary material, a perforated membrane, and pressing device liquid, such as sample catcher with level control vibration amplitude and frequency of diaphragm vibrations being puller moisture electrode comprises a tight crimp dried material, with a pulling moisture electrode is functionally and structurally combined with a vacuum device and placed, for example, below the dried material, and vacuum device comprises a vacuum pump, the tank for collecting liquid, and a check valve connected to the atmosphere, and a pulling moisture electrode is made of porous material, wherein the device is provided with one or more heat generators local or distributed heating the dried material, for example, the generator (s) directed Microwaveable heater (s) device (s) of the electrothermal heating, gas burners placed locally or throughout the volume of the drying chamber used in the process of drying material separately, in various combinations, and (or) at the same time, and as a local thermal heating device drained materials used microwave heat source, a radiator, such as directional placed in the zone of the drying of the surfaces of the material, for example, in the end part of timber, and structurally combined with the pusher moisture electrode, and ejecting moisture electrode, for example, the positive electrode electroosmotic pump constructively combined with heating (E) device (s), for example, electrothermal heating, for example, timber ends, wherein the heating device includes, for example, carbon-fiber activated material further activated material, and a heat source, such as a combined electrode electroosmotic pump in the form of an electric heater, electrically connected to an additional adjustable voltage source to control temperature and power, the activated material with the heating element is designed as a web which is covered, for example, end portions, parts, and (or) the entire desiccant material, the apparatus дополнено центрифугой для вращения осушаемого материала и начального отжима жидкости из пористого материала центробежными силами, причем осушаемый капиллярный материал, например, древесину (пиломатериалы) располагают в сушильной камере капиллярами вертикально, причем выталкивающий влагу электрод с нагревательным устройством и устройством плотного обжима осушаемого материал укреплён сверху осушаемого материала, а вытягивающий влагу электрод с устройством адсорбирования и эвакуации жидкости, устройством плотного обжима осушаемого материала, виброустройством вакуумным устройством и ёмкостью для сбора жидкости укреплены снизу осушаемого материала, причем сверху осушаемого материала может быть размещена емкость с пропиточной жидкостью определенного назначения, соединенная с выталкивающим электродом , обеспечивающим ее непрерывное или циклическое перемещение (всасывание)в материал, например, электроосмосом и силами гравитации, например, через его перфорации, причем это устройство дополнено устройством цикличного перемещения одного или нескольких электродов электроосмотического насоса, снабженных адсорбентами влаги, вдоль поверхностей осушаемого материала, например , по программе, обеспечивающей высокое качество получаемого осушаемого материала при заданной интенсивности самой сушки, например, исходно влажный осушаемый материал, например влажные кирпичи, бумага, железобетонные изделия влажные сыпучие материалы и прочие, размещены подвижно относительно электродов электросмотического насоса, например, размещены плоские неподвижные электроды с минимальным зазором относительно друг друга, например, осушаемые материалы размещены на подвижном неэлектропроводящем поддоне, например, на ленте транспортера, причем сверху и снизу и (или) с боков этого подвижного поддона, установлены электроды длиной и шириной, например равной длине ленты и ширине этого поддона, например, рабочей части ленты этого транспортера, присоединенные к разноименным высоковольтным электрическим потенциалам преобразователя напряжения, или этот материал размещен непосредственно на электропроводящем подвижном поддоне, например, электропроводящей ленте транспортера с размещенном на ней адсорбционного электропроводящего материала, конструктивно совмещенным с одним из электродов, а второй и иные электроды в виде электропроводящей (их) плоскости (ей) размещены над ним и (или) с боковых сторон от ленты транспортера, на расстоянии, достаточном для предотвращения электрического пробоя электродов, присоединенных к разноименным электрическим потенциалам, причем устройство удаления влаги из пористых материалов может быть дополнено устройством отжима влажной адсорбционной ленты этого транспортера, совмещенным, например, с его валками, и приемным устройством – емкостью для сбора этой удаленной из материалов и отжатой влаги, причем содержит, например, три электрода, причем осушаемый капиллярный материал, например, древесина, размешен в камере сушки между двумя и более взаимно подвижными электродами в знакопостоянном электрическом поле с направлением вектора электрического поля преимущественно вдоль капилляров, причем два плоских электрода могут быть плотно механически присоединены к торцам капиллярного материала, например, торцевым срезам древесины, с электрическим присоединениям их к разноименным электрическим потенциалам высоковольтного знакопостоянного преобразователя напряжения, а третий электрод, например, кольцевой, с охватом осушаемого капиллярного материала, например, ствола дерева может быть подвижным с перемещением его вдоль этих капилляров, например, с его исходным пространственным размещением возле электрода с противоположным электрическим потенциалом , и последующим его одноразовым или циклическим перемещением, с минимальным зазором, вдоль капиллярного ствола, например, между положительно и отрицательно заряженными электродами, электрически присоединёнными к выходу преобразователя напряжения, причем устройство дополнено интенсификатором осушки, например, емкостью с легко кипящей жидкостью, плотно соединенной с выталкивающим электродом, причем один из двух электродов электроосмотического насоса, выполнен пористым и погружён, например, торцевой поверхностью осушаемого материала в эту легко кипящую жидкость, например, ацетон, который посредством электроосмоса вводят в капилляры материала, с противоположной стороны удаления влаги, причем устройство снабжено и и локальным нагревателем этой легкокипящей жидкости в капиллярах материала, для нагревания ее до кипения, о последующим вытеснением образованным паром этой жидкости из осушаемого материала влаги, причем в качестве жидкости, вводимой в древесину или другой пористый материал, может быть использован, например, раствор антисептика, раствор противопожарной обработки древесины, красящий раствор и пр., причем устройство снабжено взаимосвязанной, например, через процессор, системой управления, содержащей регуляторы устройств сушки, например, для регулирования интенсивности осушки, например, регулятором интенсивности нагрева материала, регулятором производительности работы электроосмотического насоса, например , в виде регулятора напряжённости электрического поля между электродами и(или) частоты импульсов электрического поля, регулятором частоты и амплитуды звуковых колебаний, регулятором степени вакуумирования рабочей зоны, датчиками влажности, размещёнными по объёму осушаемого материала, а и и устройством (ами) коммутации электрических цепей в процессе и в конце сушки и программируемым устройством сушки пористого материала по заданной программе, причем устройство удаления влаги дополнено пористым адсорбентом, присоединенным к рабочей поверхности одного или нескольких электродов, и(или) обволакивающим весь осушаемый пористый материал, причем предельная влагоемкость этого пористого адсорбента выбирается из определенных условий, например, должна быть достаточна для вмещения всей влаги из осушаемого электроосмосом, пористого материала, причем оно дополнено устройством штабелирования материала сушки, например, древесины , и устройством его герметизации, которое выполнено из эластичного материала, например, толстого полиэтилена, кожезаменителя, например, складным, например, в виде гармошки, одеваемой на штабель из древесины и закрепляемой на одном конце штабеля с осушаемым материалом, например, на вакуумном кольце, являющимся одновременно вытягивающим электродом электроосмотической установки, причем устройство штабелирования может быть конструктивно совмещено с иными элементами устройств сушки , например, с электродами электроосмотического насоса, адсорбирующими и нагревательными элементами, причем устройство может быть выполнено в виде передвижного контейнера, например на автотранспорте, и может быть дополнено устройством герметичной упаковки высушенных материалов, например, пиломатериалов.

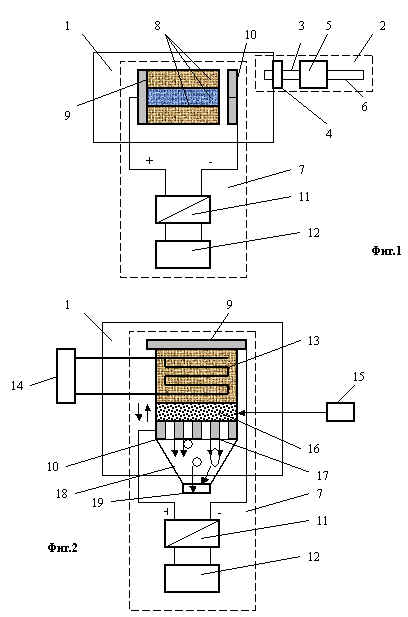

Устройство удаления влаги пористых материалов на уровне блок- схем показано на фиг.1-6 . Здесь, на этих блок-схемах ( фиг.1-6 ) применена сквозная нумерация элементов установки На фиг.1 показано простейшее устройство удаления влаги из пористых материалов, содержащее камеру сушки 1 , устройство 2 удаления влаги из камеры 1 , содержащее патрубок 3 , обратный клапан 4 , вакуумный насос 5 , и выходной патрубок с клапаном 6 , электроосмотический насос 7 , содержащий осушаемый пористый материал 8 , например, в виде древесины, два электрода 9, 10 , высоковольтный преобразователь напряжения 11 , регулируемый по амплитуде и частоте, и первичный источник напряжения 12 .

FIG. 2 показано модернизированное устройство удаления влаги из пористых материалов, снабжено нагревательными элементами 13 , присоединенными электрически к дополнительному источнику 14 напряжения, причем электроосмотический насос 7 снабжен адсорбирующим материалом 16 , соединенных с вибратором 15 , и размещенным между электродом 10 , и торцом осушаемого материала 8 причем электрод 10 выполнен с перфоратором 17 , и механически присоединен через влагосборник 18 к емкости 19 .

FIG. 3 показано модернизированное устройство удаления влаги из пористых материалов, на примере сушки пористых материалов различной формы одновременно электросмосом и односторонним (электро)термическим нагревом, причем электроды 9, 10 электроосмотического насоса выполнены в виде электропроводящих коаксиальных цилиндров, например, с перфорацией и электрически присоединенных через высоковольтный преобразователь напряжения 11 к первичному источнику напряжения 12 , между которыми размещен адсорбент 16 , полностью обволакивающий осушаемые материалы 13 , причем на внутренней поверхности цилиндрического электрода 9 размещены электронагревательные элементы 13 , электрически присоединенные к дополнительному регулируемому источнику 14 напряжения.

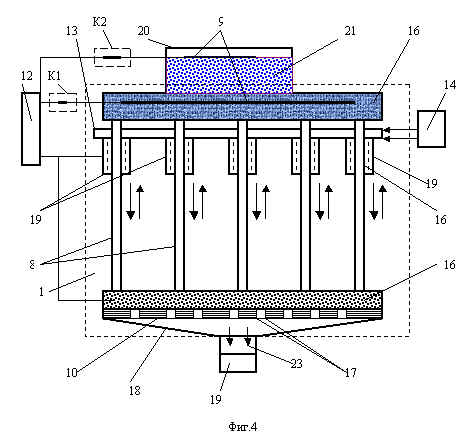

На фиг.4 показано модернизированное устройство удаления влаги из пористых материалов, для варианта осушиваемых материалов 8 , например, древисины, например, пиломатериалов, размещенных в камере 1 , например, вертикально, или горизонтально причем электроосмотический насос 7 содержит дополнительные подвижные электроды 19 , совмещенные с пористым материалом 16 , причем с боковых граней или(и)торца электродов размещены электронагревательные элементы 13 , совмещенные с реечным или иным устройством вертикального синхронного перемещения подвижных электродов 19 , причем через пористый материал 16 с уплотнителем (не показан), к верхним торцам древесины 8 присоединена емкость 20 с жидким раствором, например, антисептика, 21 причем к нижним торцам осушаемой древесины 8 присоединено и через вытягивающий электрод 10 с пористым материалом 16 вакуумирующее устройство 23 . Оно соединено через влагосборник 18 с емкостью 19 . Ключи К1,2 предназначены для коммутации цепей высокого напряжения на электроды 9 в режиме ввода в пористый материал вспомогательной жидкости , например, антисептика, красителя. Электроды 9,10 могут быть выполнены с перфорацией.

На фиг.5 показано электроосмотическое устройство сушки пористых материалов 8 в камере 1 , находящихся на подвижном поддоне, например на транспортере конвейера в движении, с непрерывным или повторно –кратковременном перемещением ленты конвейера, содержащем подвижный электрод 10 -электропроводящую ленту транспортера и неподвижный электрод 9 , размещенный над пористым материалом 8 на расстоянии предотвращающим недопущение электрического пробоя электродов 9,10 через источник 11 .

Figure 6 shows a system of interconnected control regulators drying device for a given program and by means of information from the humidity sensor 28 Designation of certain elements of this unit is similar to -scheme numbering in Figures 1-5. Here and show new elements -upravlyayuschy processor 29, managing a distributed system controllers 12, 14, 32, 34, commands the humidity sensor 28, the dried material 8 in a sealed chamber 1 through the drying led them to the program following governing bodies control-system 30 of the high-voltage converter 12 control system 31, an adjustable voltage source 14 connected to the heating element 13, the control system 33 of the vibrator 32 low frequency audio frequency, the control system 35 of the microwave generator 34 of the microwave - Heating one side of the material 8.

Consider the operation of these devices to the dynamics of drying. The simplest water removing device of porous material, FIG. 1 operates as follows. When a high voltage (30-40 kV) from a low-power high-voltage converter unit 11 to the electrodes 9, 10 causes the moisture in the dried material 8 moves due to capillary effects and electroosmotic in the ejecting direction from the electrode 9 toward the electrode 10 is pulled. Next, the dried material removed from the moisture in the form of eight two-phase medium is removed from the chamber 1 by evacuating suction device 2.

The apparatus shown in FIG. 2, removal of moisture from the porous material, a number of new modernized functional elements described above operates as follows. First material 8 to be dried is heated by passing an electric current through the heating element 13 from the source 14 and the heating rate adjusted current value by changing the voltage source 14, voltage regulation. Further, a high voltage from the high voltage transformer 11 to the electrodes 9, 10 and the electroosmotic method adsorbed material 8 remote from the moisture in the porous material 16. Evacuation of fluid from the porous material 16 is performed by sample catcher 15, followed by a translation of the moisture through the perforations 17 in the pulling electrode 10, and the water trap 18 into the container 19.

Apparatus remove moisture from porous material shown in FIG. 3 operates as follows. Dried material 8 gives the porous moisture adsorbent 16 by capillary effects and electro, the adsorption process is enhanced by heating the electrode 9 by the heating elements 13.

Device remove moisture from porous materials, for example wood drying FIG. 4 operates as follows. Movable electrodes 19, mechanically connected with one another, electrically connected to the high-voltage regulated inverter 11, a voltage moving along the timber 8 in a vertical plane and simultaneously heat the timber 8 by means of heating elements 13 and remove the vacuum device 23 the moisture outside the processing chamber 1, thereby, along with electroosmotic effect more efficient removal of water drained from timber 8, and further through the perforations of the electrodes 9, 10 outside the chamber 1. This device is equipped with a capacity of 20, coupled with the porous material 16, filled with a certain solution, allows not only to drain the material, but also added after drying electroosmosis, electrophoresis, capillary structures drained timber 8 different required technologically significant solutions of 21, for example, an antiseptic and fire and other liquid from the container 20 into timber 8 fibers. In this electro-pump mode key K1 and K2 open-closed switch.

The apparatus (5) works as follows. After a charging device (not shown) in the conveyor drying chamber containing the strip-electrode 10, stretched on drums 25, 26 are introduced the porous material 8 to be dried. After loading the material 8 in the chamber 1 to the electrodes 9, 10 is fed from the high electric potentials of the block 12 and create an electric field in the drying zone 8 And material for electric potetsial conductive tape is fed through a special spring-like electrode 24, the carbon brush. As a result, occurrence of electroosmosis coming out of the moisture of the material and absorbed by the porous adsorbent 16 which is pressed rolls 26, 27 and is then removed from chamber 1 through 18 vlagopriemnik container 19, and a pair of moisture removed from the camera device 1 two hoods. After this process is completed ochushki and dried material 8 through the unloading hopper (not shown) is withdrawn outside the chamber 1 and it is charged with another batch conveyor wet the porous material 8. This device is designed to process and implement continuous electroosmotic drying of porous material

In some modes of operation of the device (5) drying the porous material 8, for example, wood sawdust, paper pulp, bulk materials and other wet effectively by alternating installation modes by alternately using electroosmotic effects and corona discharge between the electrodes to be dried through a 9.10 8, a porous material, for example, in the initial stage of drying the porous material electroosmotic 8.This interlace mode change may be effected electric field strength in the gap between the electrodes 9, 10, for example by varying the voltage and frequency of the block 11.

Drying device (6) operates as follows. Control processor 29 receives information from the humidity sensor 28, the dried material 8, and outputs control signals to the regulators of the control system 12, 14, 32, 34, through the following control organs driven by program them - to the high-voltage converter 30 a control system voltage 12, control system 31 controlled voltage source 14 connected to the heating element 13, the low-frequency oscillator 32 to an audio frequency 33 control system 35 controls the microwave generator of the microwave system 34 - heat from one side of the porous material 8. As a result, the device provides effective dewatering drying material 8.

CLAIM

1. Moisture removal device of porous material further device comprising drying chamber, a moisture removal device of porous material in the form of an electrical device comprising two electrodes and a voltage source and the device remove moisture from the drying chamber, characterized in that a low-cost for drying capillary porous materials, substances, such as wood moisture removal device of porous material is in the form of the electroosmotic pump is controlled, for example, high capillary type, and as used in this pump capillary pores of the capillary material to be dried, then the dried material,

2. Device according to claim. 1, characterized in that the electroosmotic pump consists of an adjustable amplitude and frequency of the high-voltage converter voltage of constant sign, such as a pulse oscillator of the inductive type blocking voltage generator, high voltage transformer resonant Tesla, a high-voltage electrostatic generator Van de Graaff and other embodiments thereof, of the dried material, and two or more electrodes are electrically connected to the output, for example, the positive and negative potentials of the high voltage inverter.

3. The apparatus of para. 1.2, characterized in that the positive and negative electrodes are dimensioned and squares of equal or greater size, and the areas, such as the end surfaces of the porous material to be dried.

4. Device according to claim 1-3., Characterized in that one of the electrodes, for example, a positively charged electrode (s) is firmly attached (s) to one of the surfaces of the dried material, for example, an end, and a negatively charged electrode (s) and firmly attached or with a gap (ies) to the opposite, for example, the end surface of the dried material.

5. Device according to claim 1-4., Characterized in that one or more of the electrodes of the electroosmotic pump, draws moisture electrode, for example, the negatively charged electrode (dy) comprises (al) adsorbing device and evacuation of vaporized by the electric field, for example, cold steam and (or) of the liquid material to be dried.

6. Device according to claim 1-5., Characterized in that the adsorbing device and the fluid evacuation extracting electrode comprises a capillary wicking material, a perforated membrane and fluid extraction device, such as a vibration sample catcher regulator frequency and amplitude of the membrane oscillation.

7. Apparatus according p.1-6, characterized in that the electrode comprises a pulling device moisture tight crimp dried material.

8. Apparatus according p.1-7, characterized in that the pulling moisture electrode is functionally and constructively combined with a vacuum device, and is placed, for example, below the material to be dried.

9. Device according to claim 1-8., Characterized in that the vacuum device comprises a vacuum pump for collecting liquid tank and a check valve connected to the atmosphere.

10. The apparatus of claim 1-9., Characterized in that the pulling moisture electrode is made of porous material.

eleven. Apparatus according to para. 1-10, characterized in that it is provided with one or more local or distributed heat sources heat the material to be dried, for example, the generator (s) directed microwave radiation heater (s) device (s) of the electrothermal heating, gas burners, placed locally or throughout the volume of the drying chamber used in the process of drying material separately, in various combinations, and (or) simultaneously.

12. Apparatus according p.1-11, characterized in that the local thermal heating device drained microwave heat source materials used with emitters, such as directional placed in a drying zone one of the surfaces of the material, such as a timber end portion, and constructively aligned with the ejector moisture electrode.

13. Apparatus according p.1-12, characterized in that said extractor electrode moisture, for example, the positive electrode of the electroosmotic pump is structurally combined with the heater (s) device (s), for example, electrothermal heating, for example, timber ends.

14. Apparatus according p.1-13, characterized in that the heating device consists for example of activated carbon fibrous material, the material further activated, and the heat source, for example, combined with the electroosmotic pump electrode in the form of an electric heater, electrically connected an additional adjustable voltage source with temperature control and power.

15. Apparatus according p.1-14, characterized in that the material is activated with the heating element is designed as a web which is covered, for example, the end parts, parts and (or) the entire material to be dried.

16. The apparatus of para. 1-15, characterized in that it is supplemented by a centrifuge for rotating the material to be dried and the initial extraction of liquid by centrifugal forces of the porous material.

17. The apparatus of para. 1-16, characterized in that the capillary material to be dried, such as timber (sawn timber) is arranged in the drying chamber vertically capillaries, moisture and ejecting electrode with a heating device and the crimping dense material to be dried on top of the dried material is strengthened and pulls moisture electrode device adsorption and fluid evacuation device tight crimp dried material, sample catcher vacuum device and containers for the collection of fluid strengthened bottom-dried material, and on top of the dried material can be placed a container of impregnating a specific purpose liquid connected to the pusher electrode, providing its continuous or cyclical transfer (suction) in the material, such as electroosmosis and gravity forces, for example, through its perforations.

18. The apparatus of para. 1-17, characterized in that the device is provided with a cyclical movement of one or more electrodes of the electroosmotic pump is provided with a moisture adsorbent along surfaces of the dried material, for example, a program providing a high quality of the dried material at a predetermined intensity itself drying for example, initially the wet desiccant material, for example wet bricks, paper, concrete products moist bulk material, and the rest are placed slidably with respect to the electrodes electrotechnology pump, for example, has flat fixed electrodes with minimal clearance relative to each other, for example, drained material placed on the movable non-conductive a pallet, for example, on a conveyor belt, the top and bottom and (or) from the sides of the rolling pallet, the electrodes in length and width, for example equal to the length and width of the tape tray, for example, the working part of the conveyor belt ,. attached to heteronymic high-voltage electric potentials of the voltage converter, or the material is placed directly on the electrically conductive movable tray, for example, an electrically conductive conveyor belt with placed thereon adsorption conductive material structurally combined with one of the electrodes, and the second and other electrodes in the form of electrically conductive (their) plane (s) placed on them (or) from the sides of the conveyor belt, at a distance sufficient to prevent electrical breakdown of electrodes attached to heteronymic electric potentials, and remove moisture from porous materials, the device may be completed device pressed wet adsorption belt of transporter, aligned, for example, with its rollers and the receiving device - a container for collecting this material removed from the pressed and moisture.

19. Apparatus according p.1-18, characterized in that it comprises three electrodes, wherein the capillary material to be dried, such as wood, in the drying chamber that serves between two or more mutually movable electrodes znakopostojannom in the direction of the electric field vector of the electric field along the predominantly capillaries, and two flat electrodes may be tightly mechanically coupled to the ends of the capillary material, such as mechanical slicing wood, electrical interconnection them to heteronymic electric potentials of the high voltage of constant sign of the voltage converter, and a third electrode, for example, circular, covering drained capillary material, e.g. , a tree trunk may be movable with the movement of it along these capillaries, for example, with its original spatial placement near an electrode with an opposite electrical potential, and its subsequent disposable or cyclic displacement with a minimum clearance along the capillary bore, for example, between the positively and negatively charged electrodes electrically attached to an output of the voltage converter.

20. The device according to claim 1, 19, characterized in that the drying is completed intensifier, for example, a container of boiling liquid is easily, tightly connected to the ejecting electrode, wherein one of the two electrodes of the electroosmotic pump is made porous and is shipped, for example, an end surface dried material in the readily boiling liquid, such as acetone, which by means of electroosmosis is introduced into the capillaries of the material, on the opposite side of the moisture removal, the apparatus is provided and both local heater of low-boiling liquids in the capillaries of the material to heat it to boiling, a subsequent displacement educated the fluid steam from moisture in the material to be dried.

21. Apparatus according p.1-20, characterized in that the liquid introduced into the wood or other porous material may be used for example, antiseptic solution, fire wood treatment solution, staining solution and so forth.

22. The apparatus of para. 1-21, characterized in that it is provided with interconnected, for example via a processor control system comprising a drying device controls, for example, to regulate the intensity of drying, for example, control the heating rate of the material, productivity regulator electroosmotic pump for example, a controller of the electric field between the electrodes and (or) the frequency of the electric field pulses, control the frequency and amplitude of the sound vibrations regulator degree working area vacuuming humidity sensors positioned in the volume of the dried material, and and and the device (s) commutation electrical circuits during the drying and at the end of a programmable device and drying the porous material for a given program.

23. Apparatus according p.1-22, characterized in that the moisture removing device is supplemented with a porous adsorbent, the working surface attached to one or more electrodes, and (or) enveloping the entire porous material to be dried, the ultimate moisture content of the porous adsorbent is chosen from certain conditions, e.g. It should be sufficient to accommodate all of the drained moisture electroosmosis, porous material.

24. The apparatus of claim. 1-23, characterized in that the stacking device is completed drying material, such as wood, and its sealing device, which is made of an elastic material, such as thick polyethylene, synthetic leather, for example, folding, for example, concertina, dress up on a pile of wood and fastened at one end of the pile with a drying material, such as a vacuum ring, which is at the same time drawing out electrode electroosmotic installation, the stacking device can be structurally combined with the other elements of the drying device, for example, with the electrodes of the electroosmotic pump , adsorbent and heating elements.

25. The apparatus of para. 1-24, characterized in that the device can be designed as a mobile container such as a vehicle-based and device may be complemented by tight packing of the dried material, such as lumber.

print version

Author: Dudyshev Valery

PS material is protected.

Publication date 26.01.2005gg

Comments

Commenting, keep in mind that the content and the tone of your messages can hurt the feelings of real people, show respect and tolerance to his interlocutors, even if you do not share their opinion, your behavior in terms of freedom of speech and anonymity offered by the Internet, is changing not only virtual, but real world. All comments are hidden from the index, spam control.