Chernobyl: Part 3. ANALYSIS OF THE PROCESS OF DEVELOPMENT OF THE ACCIDENT ON THE MATHEMATICAL MODEL.

Information on the Chernobyl accident and its consequences prepared for the IAEA Report No. 1 (INSAG-1)

C O R E R A N E E

Flash drive

0. Introduction

1. Description of the Chernobyl NPP with RBMK-1000 reactors.

2. Chronology of the development of the accident.

3. Analysis of the process of development of the accident on a mathematical model.

4. Causes of the accident.

5. Preventing the development of an accident and reducing its consequences.

6. Control over radioactive contamination of the environment and public health.

7. Recommendations for improving the safety of nuclear power.

3. ANALYSIS OF THE PROCESS OF DEVELOPMENT OF THE ACCIDENT ON THE MATHEMATICAL MODEL

The RVMK-1000 centralized control system (SKK) provides a program for diagnostic parameter registration (DREG), according to which several hundred analog and discrete parameters are interrogated and stored periodically (minimum cycle time of 1 s).

In connection with the testing with a high frequency, only those parameters were recorded that were important from the point of view of analyzing the results of the tests. Therefore, the process of accident development was restored by calculation on the mathematical model of the power unit using not only printouts of the DREG program, but also instrument readings and personnel survey results.

At the estimated restoration of the process of accident development, it was very important to make sure that the mathematical model of the power unit correctly describes the behavior of the reactor, as well as other equipment and systems, precisely under the conditions in which they faced destruction. As already noted in the previous section, the reactor after 1:00 AM on April 26, 1986 worked unstably and the operators almost continuously introduced "disturbances" into the control object in order to stabilize its parameters. This allowed us to compare the actual data sufficiently reliably fixed by the registration means for a fairly large time interval with various effects on the reactor facility, with the data obtained in numerical simulation. The results of the comparison turned out to be quite satisfactory, which indicates the adequacy of the mathematical model to the real object.

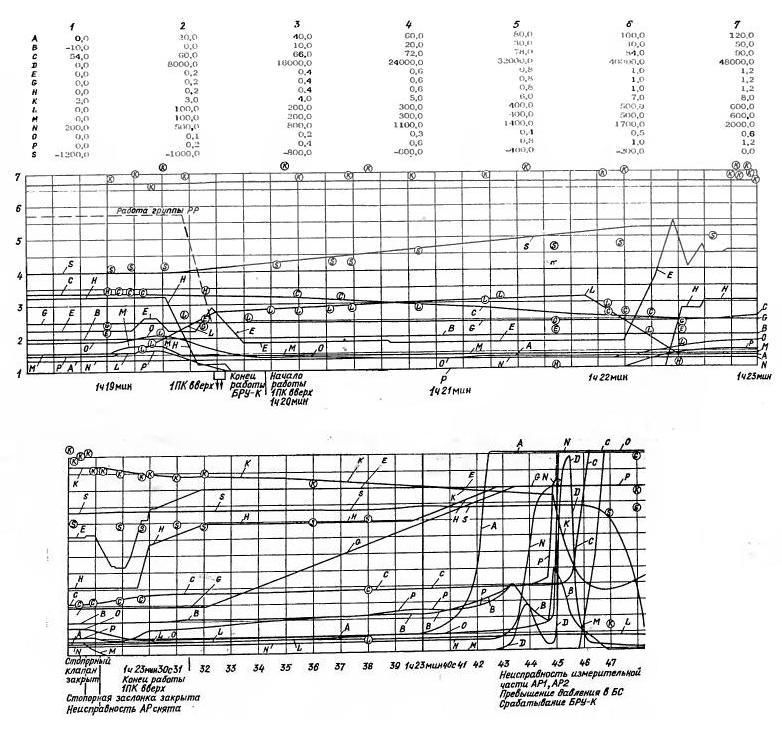

In order to better understand the influence of prehistory on the nature of accident development, the calculated data were analyzed starting from 1h 19min 00sec, i.e. 4 min before the start of the test with TG run-out (Fig. 3).

The operator began replenishing BC to prevent water levels from falling in them. After 30 seconds he managed to keep the level, increasing the flow of feed water more than 3 times. About a minute later, it was already 4 times higher than the original one.

As soon as the colder water from the BS reached the core, the steam generation decreased noticeably, causing a decrease in the volumetric vapor content, which led to the upward movement of the AP rods. After about 30 seconds they went to the upper limit switches, and the operator was forced to "help" them with PP rods, thereby reducing the operational reserve of reactivity. (This operation was not recorded in the operational journal, but without it it would be completely impossible to hold the power at 200 MW.) The operator, having moved the rods PP upwards, achieved overcompensation and one of the groups of rods AP dropped by 1.8 m.

A decrease in the generation of steam led to a slight drop in pressure. After about a minute, a high-speed reduction device (BRU-K) was closed at 1h 19min 58sec, through which excess steam was poured into the condenser. This contributed to a slight decrease in the rate of pressure drop. However, until the test began, the pressure continued to fall slowly. Over this period of time, it has changed by more than 0.5 MPa.

At 1h 22min 30sec at SCK "Skala" was obtained a printout of the actual energy release fields and the positions of all control rods. It was at this point in time that an attempt was made to "tie" the calculated and registered neutron fields.

The general characteristic of the neutron field at this instant is this: in the radial-azimuthal direction, it is practically convex, and in height it has an average two-humped head with a higher emis- sion in the upper part of the core. Such a field distribution is quite natural for the state in which the reactor was located: the burnt active zone, almost all control rods at the top, volumetric vapor content in the upper part of the core is much larger than below, 135Xe poisoning in the central parts of the reactor is greater than in the peripheral ones.

At 1h 22min 30sec, the reactivity margin was only 6-8 rods. This is at least twice less than the maximum permissible reserve, established by the technological regulations of operation. The reactor was in an unusual, non-regulated state, and to evaluate the subsequent development of events it was extremely important to determine the differential efficiency of the control rods and A3 at real neutron fields and the multiplying characteristics of the core. Numerical analysis showed a high sensitivity of the error in determining the efficiency of control rods to the error in recovering the high-altitude field of energy release. If we also take into account that at such small power levels (~ 6% 7 7%) the relative error of the field measurement is significantly higher than under nominal conditions, then it becomes clear that a very large number of design options need to be analyzed to verify the reliability or The inaccuracy of this or that version.

By 1 h 23 min the parameters of the reactor were the closest to the stable for the considered period of time, and the tests began. A minute before, the operator had drastically reduced the flow of feed water, which led to an increase in the temperature of the water at the entrance to the reactor with a delay equal to the time of passage of the coolant from the BS to the reactor. At 1 h 23 min 04 sec, the operator closed the SRK TG No. 8 and the turbogenerator started running. Because of the decrease in steam consumption from the BS, its pressure began to grow poorly (on average, at a rate of 6 kPa / s). The total flow of water through the reactor began to fall due to the fact that four of the eight MCPs were operating from a "running" turbogenerator.

The increase in steam pressure, on the one hand, and the reduction in the flow of water through the reactor, as well as the supply of feedwater to the BS, on the other, are competing factors that determine volumetric vapor content and, consequently, reactor power. It should be specially emphasized that in the state in which the reactor got into, a small change in power results in a volumetric vapor content directly affecting the reactivity that is many times stronger than at the rated power. The competition of these factors ultimately led to an increase in capacity. This circumstance could be the reason for pressing the button AZ-5.

Fig. 3. Calculated recovery of the accident process on a mathematical model:

A, D - neutron power,%;

B is reactivity of the reactor;

C - pressure in the drum-separator, atm;

E, G, AND - position of the rods AP-1, AP-2 and AP-3, respectively;

K, L, M - heat carrier flow (m3 / c), feed water (kg / s) and steam (kg / s) in one loop, respectively;

N - temperature of fuel, оС;

О, Р - mass and volume vapor content at the exit from the zone;

S - water level in the drum-separator, mm;

About - points from printout DREG

Button A3-5 was pressed at 1 h 23 min 40 sec. The introduction of the A3 rods began. By this time, the AP rods, partially compensating for the previous increase in power, were already in the lower part of the core, and the work of personnel with an unacceptably small operational reserve of reactivity led to the fact that practically all the remaining absorber rods were in the upper part of the core.

Under the circumstances, the violations committed by the personnel resulted in a significant decrease in the efficiency of A3. The total positive reactivity, which appeared in the core, began to grow. After 3 seconds the power exceeded 530 MW, and the overclocking period became much less than 20 seconds. The positive steam effect of reactivity contributed to the deterioration of the situation. Partially compensated for the reactivity introduced at this time only the Doppler effect.

The continued reduction in water flow through the reactor's reactor under conditions of increased power led to intense vaporization, and then to a heat-transfer crisis, fuel heating, its destruction, a boiling effervescence of the coolant, into which particles of destroyed fuel fell, a sudden increase in pressure in the TK, their destruction and thermal explosion , Which destroyed the reactor and part of the structure of the building and led to the release of active fission products into the external environment.

Steam formation and a sharp increase in temperature in the core have created conditions for the occurrence of steam zirconium and other chemical exothermic reactions. Eyewitnesses saw their manifestation in the form of fireworks of emitted hot and hot fragments.

As a result of these reactions, a mixture of gases containing hydrogen and carbon monoxide was formed, capable of thermal explosion when mixed with air oxygen. This confusion could occur after the depressurization of the reactor space.

Comments

Commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.