DISK PARAMETERS

Alloy wheels are one of the main parts that affect the appearance of the car. Made of lightweight aluminum alloys using injection molding technology. Alloy wheels have very high strength characteristics. Painted with special anti-corrosion paints and varnishes.

Alloy wheels are one of the main parts that affect the appearance of the car. Made of lightweight aluminum alloys using injection molding technology. Alloy wheels have very high strength characteristics. Painted with special anti-corrosion paints and varnishes. But this is not the only advantage of light alloys. There are other reasons for buying light alloy wheels:

- Weight reduction of the wheel and as a result, weight reduction improves the acceleration dynamics, reduces the load on the engine and transmission, reduces fuel consumption, increases the smoothness of the course;

- The use of an alloy wheel improves the cooling of the brake unit, due to the high thermal conductivity of the alloy and the better blowing due to the design;

- The technology of production of cast discs provides high accuracy, which minimizes imbalance, and therefore, the balancing can be done more accurately;

- A multi-layer coating ensures the protection of the wheel from the environment.

The correspondence of the drive to the car is determined by the following basic parameters:

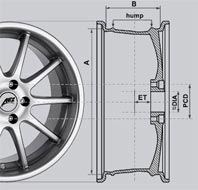

A - landing diameter (measured in inches) - diameter of the ring part of the rim on which the tire rests.

A - landing diameter (measured in inches) - diameter of the ring part of the rim on which the tire rests. B - the width of the rim (measured in inches) - the distance between the inner surfaces of the side beams of the wheel. Determines the possible width of the profile of the installed bus

The width of the tire profile - a parameter directly related to the landing width of the rim - has a significant impact on economy, dynamics, maximum speed, handling, braking distance. A wider wheel has a larger contact patch and therefore better grip with the road, but there is more rolling resistance and flow of counter-air. As a result: the dynamics of overclocking deteriorates, manageability improves.

ET ( departure ) - the distance from the plane of the wheel adjacent to the hub, to the plane passing through the middle of the landing width of the rim (measured in millimeters). For each car, the manufacturer provides a list of permissible options for installing wheels. There are both "positive" and "negative", the latter is found mainly in SUVs. Departure is not a constant value and, depending on the design features of the disk, can fluctuate up to 10 mm for the same car. The majority of passenger cars are from 30 to 40 mm.

If there are significant deviations in the departure from the recommended tire, they may be caught by wheel arches or suspension elements. In addition, the installation of wheels with outreach, which is much smaller than the one envisaged, leads to a significant decrease in the stability of the car in bends, increased sensitivity of the steering to road irregularities and uneven braking forces.

DIA - The diameter of the central hole must correspond (with minimal clearance) to the diameter of the centering projection on the car's hub (measured in millimeters). A deviation of its magnitude in the larger side is allowed. In this case, the centering rings (included in the set of light-alloy wheels) are used to install the wheel.

Hump are small annular projections on the surface of the disc, made for a tubeless tire. In turns, they improve the fixation of the bead of the tire on the disc, thereby preventing the depressurization of the wheel.

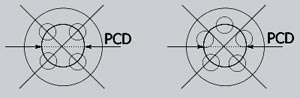

PCD is the diameter of the circle of the centers of the fixing holes (measured in millimeters). This value must match the standard one, otherwise it will not be possible to secure a reliable fixation of the wheel to the hub. A deviation of even 2 mm will lead to a skewing of the fastening elements (bolts).

PCD can be calculated by measuring the distance between the centers of the far fastening holes (this can be done with a conventional ruler without removing the wheels from the car)

-

For disks with four fixing bolts (or nuts), the PCD is equal to the distance between the centers of the far (opposite) bolts or nuts.

For disks with four fixing bolts (or nuts), the PCD is equal to the distance between the centers of the far (opposite) bolts or nuts. - For disks with five fastening bolts (or nuts), the PCD is equal to the distance between the centers of distant (any non-adjacent) bolts or nuts multiplied by a coefficient of 1,051

For example: 6.5 J 15 5 × 114.3 ET45 d54.1

6.5 - The width of the disc in inches. (B)

15 - Diameter of the disc in inches (D)

5 × 114.3 - The number of bolts (or nuts) in our case 5. The diameter on which they are located,

Called PCD (Pitch Circle Diameter) and in our case it is equal to 114.3 mm .

ET45 - Departure ( ET ) is measured in mm. And in our case it is equal to 45 mm .

D54.1 - Diameter ( DIA ) is measured in mm. And in our case is equal to 54.1 mm .

6.5 - The width of the disc in inches. (B)

15 - Diameter of the disc in inches (D)

5 × 114.3 - The number of bolts (or nuts) in our case 5. The diameter on which they are located,

Called PCD (Pitch Circle Diameter) and in our case it is equal to 114.3 mm .

ET45 - Departure ( ET ) is measured in mm. And in our case it is equal to 45 mm .

D54.1 - Diameter ( DIA ) is measured in mm. And in our case is equal to 54.1 mm .

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.