GLASSMAT - glass matting technology.

This new unique technology allows for high-quality personalization of virtually any glass. Tableware for hotels and restaurants, prestigious awards, the design of showcases and mirrors, numbers on car windows, etc. There is no such glass surface that can not be decorated with GlassMat ! At the same time, the resulting image on the glass is "eternal", it can not be washed off or scraped. Matte surface has a fine-grained, "silk" surface, on which there are no fat fingerprints.

The main component of the technology is a special paste GlassMat. For those products that are difficult to treat with paste (for example, objects of irregular or circular shape), GlassMat fluid is used. To form a protective coating on objects treated with paste or liquid, use a regular adhesive tape.

WORK WITH The technology of working with paste is extremely simple and does not require large investments of funds. Schematically, the process of manufacturing products can be described as follows:

1) It is necessary to make a template . To create a template, it is most convenient to use a cutting plotter or, in extreme cases, a stationery knife.

2) Glue on your template a sheet of mounting film, equal in size to the template. Now your template is a three-layer sandwich: a paper substrate, a vinyl film with an adhesive layer and a mounting film on top.

Before applying the template to the glass object, the glass must be treated with any glass cleaner and wiped dry with a towel or napkin. Place the template on the glass as required. Fix it to the glass with one piece of paper tape along the top edge.

3) Unbend the template from the glass so that it sticks to the adhesive tape, as the door hinges. Remove the paper substrate from the template, exposing the adhesive layer (do not throw out the substrate - it's still useful.) Gently glue the template using a plastic spatula for this.

4) Carefully remove the mounting film from the template. Put a paper backing on top of the template with a plastic spatula. It is necessary that all parts of the image are securely glued to the glass, and there is no air bubbles between the vinyl and the glass. The paper substrate will not allow the blade to catch small parts.

5) Using a mounting or clerical knife, remove those parts of the image where you want to get a matte surface. Do not try to cling details to the edge - so you'll probably damage the even edge of the picture. Instead, make a small incision in the center of the part, insert a mounting knife into the slot and slowly and carefully separate the part from the glass. After you have separated all necessary parts from the glass, cover the template with a paper backing and once again iron it with a plastic spatula.

5) Using a mounting or clerical knife, remove those parts of the image where you want to get a matte surface. Do not try to cling details to the edge - so you'll probably damage the even edge of the picture. Instead, make a small incision in the center of the part, insert a mounting knife into the slot and slowly and carefully separate the part from the glass. After you have separated all necessary parts from the glass, cover the template with a paper backing and once again iron it with a plastic spatula.

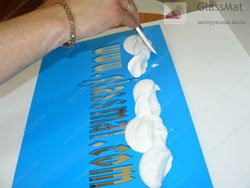

6) Carefully check to see if there are any remaining glue particles on the matt glass areas from the vinyl film. Gently remove them with your fingernail. Do not use any windshield wipers for this - they can destroy the entire adhesive layer on the vinyl. Seal with strips of vinyl or paper tape all the areas that you do not intend to matte, but where the paste can accidentally get to. Apply a thick strip of GlassMat paste next to your image.

7) ATTENTION! Do not pour the paste directly onto the image - as a result, it can turn out uneven !!!

8) Using a plastic mounting shovel, quickly apply the paste on the image so that it covers all parts with a thick layer. Never use a brush for this! Leave the paste on the glass for 7 minutes. After 7 minutes with the help of the same scapula, remove the paste from the glass or assemble the paste in a jar if you intend to use it again. Rinse the surface of the glass well enough that no paste remains on the template.

9) Remove the pattern under the stream of water, trying to do it so that a jet of water gets between the glass and the template. Rinse thoroughly and dry the glass. Now your picture will remain on the glass forever!

USING The technology of working with a liquid is also simple and does not require large investment of funds, as it is when working with paste.

Schematically, the process of manufacturing products can be described as follows:

- Take a plastic container that is larger in volume than the object selected for processing.

- Place the object selected for processing in an empty container. - Fill the container with water to the level required for engraving.

- Remove the object from the container and mark the water level on the outside of the container. Pour out the water. Dry the container itself and the object.

- Fill the container with liquid GLASSMAT to the marked level.

- Slowly lower the object into the container; Prevent its possible movement in the water, for example, filling it with water. Leave it for 15 minutes.

- At the end of the specified time, remove the object from the container.

- Wash the object with soap and water. Dry it up.

- Pour the GLASSMAT liquid into its original packaging, as it will not be removed. Liquid can be used repeatedly.

The product is ready.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.