Copying of statuettes. Mold making for casting.

For example, copying a figure of a cute cat, we show one of the ways of making a mold for polyurethane casting , which is simply necessary for pulling out an animal with wool, full of scoring and negative angles.

For example, copying a figure of a cute cat, we show one of the ways of making a mold for polyurethane casting , which is simply necessary for pulling out an animal with wool, full of scoring and negative angles.

To increase the volume of the figure, we used paraffin. You can use clay, but it spoils the shape and it's more difficult to work with. The paraffin was melted and poured into a container with a layer of about 5 mm. That's the amount of space we want to leave for the future shape - 5mm around the cat. They waited for the paraffin to freeze until the phase at which it does not flow, but remains plastic. From the bottom of the shape of the knife pieces of the necessary size are cut off and applied to the figure.

As a result, it turned out fat (from paraffin in the literal sense of the word), replenished by 5 mm along the perimeter of the cat.

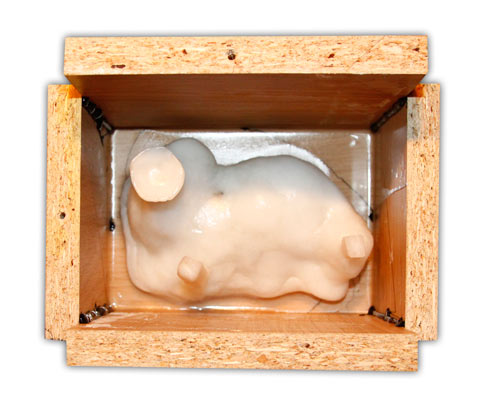

The paraffin wax is laid on the base with a pre-melted bottom for a close fit to the bottom of the formwork. For the uniform distribution of polyurethane and the release of the accumulated in the form of air, two air ducts and a filler neck were made, which you see sticking upward from the bulk of the paraffin.

A box is glued from the available dsp blanks.

Gypsum was poured into the formwork. After setting the gypsum, the formwork was removed. The gypsum form with paraffin inside was sent to the oven at 120 degrees to soften and remove paraffin and release the cat.

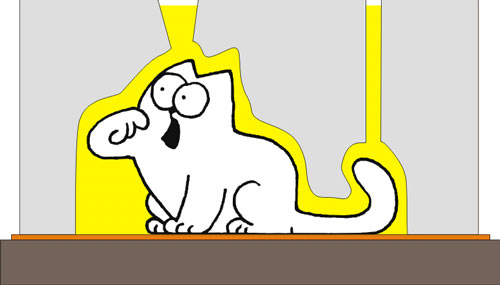

The released cat was treated with a separating grease, installed on the base of the formwork and covered with a gypsum casing. Since the photos at this stage do not reflect the depth of the depths, we are using the skills of three-dimensional modeling of virtual reality, as if looking inside the process, recreated the picture from the inside. In the role of the orange strip in the picture in our case was a millimeter layer of paraffin, which sealed the connection of the casing and the base of the cat with the base of the formwork, so that the molded polyurethane did not flow out of the mold. As the dear reader has already guessed, polyurethane is indicated in yellow.

After curing the elastic form, thanks to the separating lubricant, the structure was disassembled after 12 hours.

View from the outer and the back of the elastic form.

Immediately the gypsum was prepared and poured into a mold through a sieve.

In an hour, two clones of the original model were obtained.

This form can be turned to the wrong side, while it will withstand such treatment for many cycles of use.

Comments

Commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.