Homemade plasmatron

The principle of operation of most plasmatrons with a power from several kW to several megawatts is practically the same.

Between the cathode, made of refractory material, and an intensively cooled anode, an electric arc burns. Through this arc, the working body (PT) is blown - a plasma-forming gas, which can be air, water vapor, or whatever. The ionization of PT takes place, and as a result, the output is the fourth aggregate state of matter, called plasma. Between the cathode, made of refractory material, and an intensively cooled anode, an electric arc burns. Through this arc, the working body (PT) is blown - a plasma-forming gas, which can be air, water vapor, or whatever. The ionization of PT takes place, and as a result, the output is the fourth aggregate state of matter, called plasma.

In powerful apparatuses along the nozzle a coil of electromagnet is put, it serves to stabilize the plasma flow along the axis and to decrease the wear of the anode.

In this article, the second design is described; The first attempt to obtain a stable plasma was not a particularly successful one. After studying the device "Alplaz", we came to the conclusion that it is probably not worth repeating it one by one. If anyone is interested - everything is very well described in the instructions attached to it.

Our first model did not have active anode cooling. As a working fluid, steam was used from a specially constructed electric steam generator - a sealed boiler with two titanium plates immersed in water and connected to a 220V network. The cathode of the plasmatron was a 2 mm diameter tungsten electrode, which quickly burned off. The diameter of the aperture of the anode nozzle was 1.2 mm, and it was constantly clogged. It was not possible to obtain a stable plasma, but there were still glimpses, and this stimulated the continuation of the experiments.

In this plasma generator, the steam-water mixture and air were tested as the working fluid. The output of the plasma was intensified with water vapor, but for stable operation it must be heated to a temperature of not one hundred degrees, so as not to condense on the cooled nodes of the plasmatron. Such a heater has not yet been made, so experiments are still continuing only with air.

Photos of the interiors of the plasmatron:

The anode is made of copper, the diameter of the nozzle opening is from 1.8 to 2 mm. The anodic block is made of bronze, and consists of two hermetically welded parts, between which there is a cavity for pumping a cooling liquid - water or antifreeze.

The cathode is a slightly pointed tungsten rod with a diameter of 4 mm, obtained from a welding electrode. It is additionally cooled by the flow of a working fluid fed at a pressure of 0.5 to 1.5 atm.

Here is the completely disassembled plasmatron:

The power supply is supplied to the anode through the tubes of the cooling system, and to the cathode through the wire, attached to its holder.

Running, i.e. Ignition of the arc, is performed by twisting the cathode feeding handle until the moment of contact with the anode. Then the cathode should be immediately removed to a distance of 2..4 mm from the anode (a pair of knob turns), and an arc continues to burn between them.

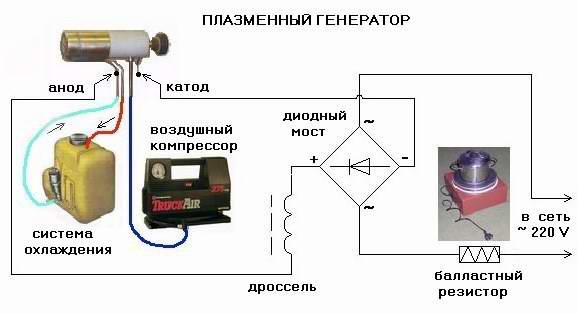

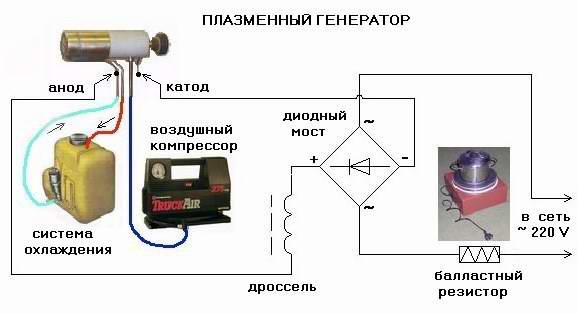

Power supply, connection of hoses of air supply from the compressor and cooling system - in the following scheme:

As a ballast resistor, any suitable electric heating device with a power of 3 to 5 kW can be used, for example, to select several boilers connected in parallel.

The reactor rectifier should be rated for current up to 20 A, our specimen contains about a hundred coils of thick copper wire.

Diodes fit any, designed for a current of 50 A and above, and a voltage of 500 V.

CAUTION!

THIS APPLIANCE USES

FREE TRANSFORMER SUPPLY FROM THE NETWORK!

The air compressor for supplying the working fluid is taken by the car, and for the pumping of the cooling liquid in a closed loop, an automotive glass washer is used. Power supply to them is supplied from a separate 12-volt transformer with a rectifier.

A little bit about the plans for the future:

As practice has shown, this design also turned out to be experimental. Finally, stable work was obtained within 5 to 10 minutes. But it is still far from complete perfection.

Replaceable anodes are gradually burned out, and making them from copper, and even with carving, is difficult, it would be better to be without thread. The cooling system does not have direct fluid contact with the exchange anode, and because of this the heat exchange leaves much to be desired. More successful would be a direct-cooling option.

Details are machined from the ready-made semi-finished products, the design as a whole is too complex for repetition.

It is also necessary to find a powerful uncoating transformer, without it it is dangerous to use a plasmatron.

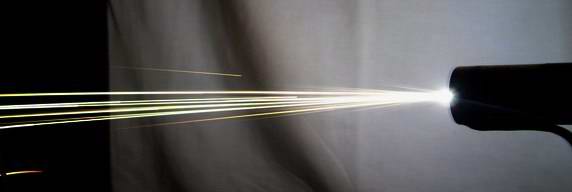

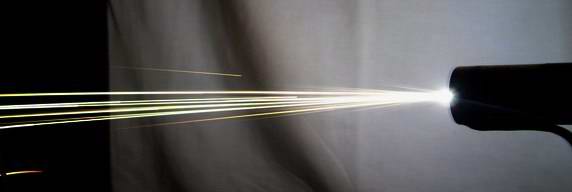

And at the end, still pictures of the plasmatron when cutting wire and steel plates. Sparks fly almost a meter

|

Between the cathode, made of refractory material, and an intensively cooled anode, an electric arc burns. Through this arc, the working body (PT) is blown - a plasma-forming gas, which can be air, water vapor, or whatever. The ionization of PT takes place, and as a result, the output is the fourth aggregate state of matter, called plasma.

Between the cathode, made of refractory material, and an intensively cooled anode, an electric arc burns. Through this arc, the working body (PT) is blown - a plasma-forming gas, which can be air, water vapor, or whatever. The ionization of PT takes place, and as a result, the output is the fourth aggregate state of matter, called plasma.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.