Free gasoline make the house yourself!

Manual for the manufacture of a small home appliance 100% of a gasoline substitute of any brand from water and domestic gas entering the apartment , as well as a description of the technology of its manufacture.

general description

The liquid - methanol (methyl alcohol) obtained with the help of this description.

Methanol in its pure form is used as a solvent and as a high-octane additive to motor fuel, and also as the most high-octane (octane number is 150) gasoline. This is the same gasoline, which is filled with tanks of racing motorcycles and cars. As shown by foreign studies, the engine running on methanol, is many times longer than using conventional gasoline, its power is increased by 20% (with the engine working at the same time). The exhaust of the engine running on this fuel is environmentally friendly and there are practically no harmful substances when testing it for toxicity.

A small-sized apparatus for obtaining this fuel is easy to manufacture, does not require special knowledge and scarce details, is trouble-free in operation.

Its performance depends on various reasons, including the size.

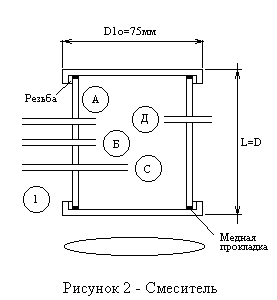

The apparatus, scheme and description of the assembly which we offer to your attention, at D = 75 mm gives three liters of finished fuel per hour, has a weight of about

Attention: methanol is a strong poison. It is a colorless liquid with a boiling point of 65 ° C, has a smell similar to the smell of ordinary drinking alcohol, and is mixed in all respects with water and many organic liquids. Remember that 30 milliliters of methanol drunk are deadly !

The principle of operation and operation of the apparatus

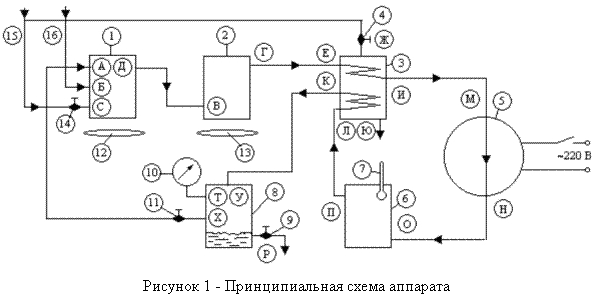

Tap water is connected to the "water inlet" (15) and, going further, is divided into two streams: one flow through the tap (14) and the opening (C) enters the mixer (1) and the other flow through the tap (4) and the hole (G) goes into the refrigerator (3), passing through which water, cooling the synthesis gas and condensate of gasoline, leaves through the hole (10).

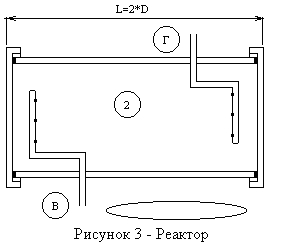

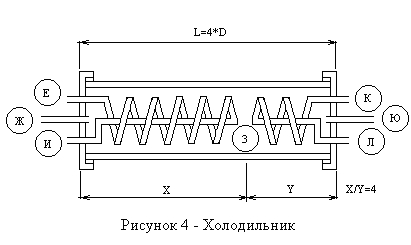

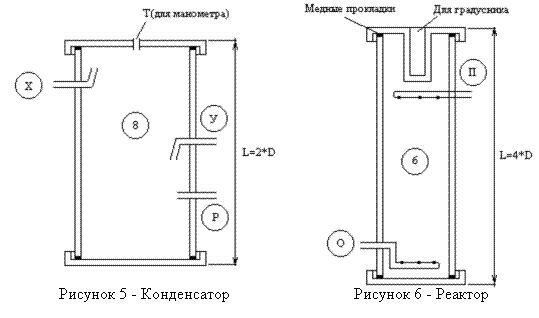

Household natural gas is connected to the pipeline "Gas inlet" (16). Then the gas enters the mixer (1) through the hole (B), in which, mixed with the water vapor, it is heated on the burner (12) to a temperature of 100-120 ° C. Then, from the mixer (1) through the hole (D), the heated mixture of gas and water vapor enters through the hole (B) into the reactor (2). The reactor (2) is filled with catalyst No. 1, consisting of 25% nickel and 75% aluminum (in the form of chips or grains, industrial grade GIAL-16). In the reactor, synthesis of gas occurs under the influence of temperature from 500oC and higher, obtained by heating the burner (13). Further, the heated synthesis gas enters through the hole (E) into the refrigerator (3), where it must be cooled to a temperature of 30-40 ° C or lower. Then the cooled synthesis gas through the hole (I) leaves the refrigerator and through the opening (M) enters the compressor (5), which can be used as a compressor from any household refrigerator. Then, the compressed synthesis gas with a pressure of 5-50 through the hole (H) leaves the compressor and enters the reactor (6) through the hole (O). The reactor (6) is filled with catalyst No. 2, consisting of 80% copper chips and 20% zinc (ICI composition, brand SNM-1 in Russia). In this reactor, which is the most important unit of the apparatus, a pair of synthesis gas is formed. The temperature in the reactor should not exceed 270 ° C, which can be checked with a thermometer (7) and adjusted with a tap (4). It is desirable to maintain a temperature in the range of 200-250 ° C, and can be lower. Then the gasoline vapor and the unreacted synthesis gas through the hole (P) exit the reactor (6) and enter through the hole (A) in the refrigerator (3), where the gasoline vapor condenses and through the hole (K) leaves the refrigerator. Further, the condensate and the unreacted synthesis gas enter through the hole (Y) into the condenser (8), where the finished gas is stored, which leaves the condenser through the opening (P) and the tap (9) into any container.

The hole (T) in the condenser (8) serves to install a pressure gauge (10), which is necessary for controlling the pressure in the condenser. It is maintained within 5-10 atmospheres or more, mainly with the help of a tap (11) and partly a tap (9). The opening (X) and the tap (11) are necessary to exit the unconverted synthesis gas from the condenser , which is recirculated back to the mixer (1) through the hole (A). The crane (9) is adjusted so that pure liquid gasoline constantly leaves without gas. It will be better if the level of gasoline in the condenser will increase, than decrease. But the most optimal case, when the level of gasoline will be constant (which can be controlled by built-in glass or some other method). The crane (14) is adjusted so that there is no water in the gasoline, and in the mixer the steam is formed better less than the larger.

Starting the unit

Open the gas access, the water (14) while closed, the burners (12), (13) work. The valve (4) is fully open, the compressor (5) is on, the cock (9) is closed, the cock (11) is fully open.

Then, the water access tap (14) is slightly opened, and the tap (11) regulates the required pressure in the condenser, controlling it with a pressure gauge (10). But in no case do not close the cock (11) completely !!! Then, after five minutes, the temperature in the reactor (6) is adjusted to 200-250 ° C by the valve (14). Then, slightly open the tap (9), from which a stream of gasoline should go. If it will go constantly - slightly open the cock, if there is gasoline mixed with gas - open the cock (14). In general, the better the tuning of the device, the better. The water content of gasoline (methanol) can be checked with an alcoholometer. The density of methanol is 793 kg / m3.

This device is preferably made of stainless steel or iron.

All parts are made of pipes, copper pipes can be used as thin connecting pipes.

In the refrigerator, it is necessary to keep the ratio X: Y = 4, that is, for example, if X + Y = 300 mm, then X should be equal to

Well, that's probably all. In conclusion, I would like to add that this design for home production of auto fuel was published in one of the numbers of the magazine "Parity".

The method of obtaining gasoline from gas and water

Comments of the author-inventor Gennady Nikolaevich Vaks.

Question: What is the consideration regarding the number of necessary compressors.

Answer: My installation of 74 codes, when gasoline cost something about 40 cents and when I spitefully made this machine, was designed for high pressure and I needed two compressors.

Now we have perfected it, calculated it, it turns out that we can conduct the process by supplying the normalized air.

This simplification was due to the creation of pressure jumps in the magnetic reactor.

There, pulses resembling claps appear inside the environment.

These claps and their generator are the invention that we brought into development.

Most of the things that we have described in connection with the methanol plant are well known.

I'm not a chemist, I'm a physicist and I took data from literature.

The new that we also made is a very compact heat exchanger.

And finally : if in classical reactors producing methanol (there are many of them, they are common), the granulometric composition of spherical catalyst pellets usually ranges from 1 to

Q: You recommend three catalysts: copper oxide, zinc oxide and cobalt oxide. With cobalt is very difficult position. Application of cobalt slightly increases the efficiency?

Answer: I can not say. The chemical composition of the catalyst itself is taken from classic books. The first facilities for producing methanol worked with a catalyst only from zinc oxide. This is in principle zinc white, white powder. But later chemists began to make and on oxide of copper and oxide of chromium, oxide of cobalt. There are a huge number of reports. In SPST a whole rack stands. These catalysts are more effective than zinc oxide. The proposed method - grinding old " silver " coins, they consist of nickel and copper - gives a good catalyst. They, these sawdust, of course, must be burned, oxidized.

Question: And you can not add chrome?

Answer: You can not add. Apparently, the optimal catalyst is not yet known. So I think that we will just have to try.

Question: The circuit must be airtight. But the catalysts will have to be removed and loaded.

Answer: Regarding the welding of this system. We have recorded that the synthesis reaction proceeds at 350 ° C. Therefore, if they gave a choke according to the scheme and someone did a little wrong, the carbon monoxide, hydrogen and vaporous methanol, dangerous gases could leak into the room. We gave a recommendation - to brew, and this recommendation, in principle, remains. Well, if someone makes a cork with all the precautions, of course, with a copper gasket, and not some other one, to ensure the tightness of the process and at the same time the dismantling , it probably is possible. But there is no certainty, so it is necessary not to be too lazy - to brew, then to boil, pour and brew again, with argon.

Question: The circuit diagram of the converter is given in the journal, but nowhere is there any indication of the technological hole.

Answer: The technological hole is suitable for anyone, so that you can only fill up the powder. Concerning the need to compact the powder, I want to emphasize the following again. In the converter there is both an oxidizer and a reducing agent - methane and oxygen. In sinuses this mixture is explosive, but if it is in some kind of powdered medium, there is no danger. In the acetylene tanks in the pipeline, copper flame-retarding veins are always laid, since the flame does not pass through the capillary back. So we say: you need to fill the converter, shake it and fill it again. So that there are no sinuses. In the sinuses, there may not be a big one, but an explosion, a clap.

Question: Is the vertical location of the reactor mandatory ?

Answer: The vertical is mandatory.

Question: Are high-temperature coolers horizontal?

Answer: There are several subtleties there that must be observed. Recently people came: they did - and they went gas through a pipe. But they put the collector, well, of the type that is on the sink, the knee, so that the water could pass, but the gas could not.

Question: You write - you must warm up before starting. That is a high-temperature heat exchanger ...

Answer: If you paid attention, the process is described in several formulas. First - in the absence of oxygen. The reaction goes endothermic, absorbing heat. It will not happen if you do not let down the heat. After you apply oxygen, increasing the pressure - there you have a special screw - already burning starts to go. In principle, this is not combustion, this is an incomplete oxidation. But even then it goes with the release of heat. And you already do not need burners. They are only needed at the beginning of the process.

Question: Ejector: there, according to the scheme in the magazine, the outlet for methane

Answer: Here is a small mistake, it is necessary to correct it.

When

Question: Is there any mesh that should be in front of the ejector against clogging?

Answer: Yes, it is necessary to limit the grid. I have overlooked this, thank you for the amendment.

Question: Is it possible to make the catalytic pump loading port dismountable? If it is possible, then how to compact?

Answer: The catalytic pump is the most important part. It is better to brew there. In principle, the pump should serve a very long time. The main disease of all reactors where a catalyst is used is the catalyst, after a while, as the chemists say, is poisoned. Let's say you have an admixture in your gas - sulfur or something. A film appears on the surface of the granules. Due to the vibration that we produce, the catalyst self-cleaning. This is facilitated by the fact that ferrite is more abrasive than zinc oxide - it is very soft. Therefore, poisoning of the surface is eliminated, and the working capacity of the catalyst is extended.

Question: What is the diameter of the dispersant ?

Answer:

Question: How is the percentage ratio between methane and water regulated?

Answer: It is regulated by temperature and, in turn, by voltage and degree of vibration. In general, this process is very complicated. The system of control and measuring devices for such processes occupies a solid room. I was at the Tallinn methanol plant and I saw it. Complex system. Of course, we could not repeat it. But still, to implement the process, all this instrumentation, all this feedback we reduced to one wick. The smaller the flame, the less remains for you unreacted methane, hydrogen, carbon monoxide. The more they do not react, the more the flame wicks on the outlet. And you will already optimize the process. Because the gas comes from the network evenly, it's a constant. Before the operator, the main task is to do so that the wick decreases. To this end, the temperature is regulated on the disperser , and the air supplied. Day or two will spend and learn how to regulate.

Question: An ejector mixer is shown, but the size of the delivery tube is not given.

Answer: This diameter does not matter much. It can be 8-10 millimeters.

Question: Is the gas pressure in the pipeline sufficient?

Answer: There is such pressure , so let it be. You still can not not increase it, do not decrease it.

Question: What about the air pressure?

Answer: It really does not matter. For what do we have on the compressor and this pressure sensor, more precisely the pressure regulator. The point is that this oxygen reaction should have very accurate values - from 2 to 4 percent of oxygen relative to methane. Methane should be 98 - 96%. In fact, we have a compressor with this pressure regulator playing the role of an oxygen dispenser, so that oxygen comes in a strictly dosage amount. If you give more oxygen, then the process will not work, but there will be a simple burning of methane. The task of the compressor is not to do a lot of pressure. All the same, it runs from the nozzles, where the ejector is, and it will be what the gas pressure in the distribution network is. The compressor is quite reliable, and can operate in continuous mode. If you put the maximum in the refrigerator, the compressor is practically working without shutdowns. It has a great safety margin.

Question: And if freon pairs fall? After all, the compressor is filled with freon oil. J

Answer: If you look carefully, there is made so that the oil can not go. You put up the phone and it's okay . And if it does, it will roll through the system, that's all.

Question: Is it possible to replace gas burners with electric heaters?

Answer: You can.

But it's expensive, probably?

Electricity is more expensive than gas.

Gas can be taken directly from one burner gas stove.

The length of the flame is approximately 120 -

Question: How to get ferrite powder?

Answer: I can give you advice on where to take it. In the White Church, near Kiev. There is a factory there. We need not iron, but kerite . We need ceramics. Iron will be oxidized . Armor cores (J) are suitable. They are not rigid, they are loose, but not all.

Question: But there is, probably, an easy way to get fine ceramics?

Answer: I do in a conventional mortar, grinding holes through a hole in a rag. First heat the material in an oven or on a gas and then throw it into the water. It will not burst, but will be covered with small cracks, after which it can be ground in a mortar.

Question: Does the heat exchanger brew?

Answer: You can brew. With him you will not have any problems.

Q: How tight is the temperature control?

Answer: Not very hard. Within 100oC. Of course, you could offer a thermocouple. But most people could not graduate . Platinum thermocouples are also very expensive. The easiest way is thermo-colors or even alloys. Each has its own melting point. There must be an alloy of the type of high-melting solder.

Q: How do I start the installation?

Answer: Turn on the burner first. Throughout the system, gas is discharged. First of all, light the wick. The gas begins to pass through the dispersant and is saturated with water. On the final canister, at the very end, you light the wick, the wick begins to burn strongly. The gas is just burning. Nothing happens. And turn on the entire electrical part. That is, the dispersant is already beginning to work actively, the saturation is active, the burners are burning. The temperature rises to 350 - 800оС. Methane conversion begins, which turns into carbon monoxide and hydrogen. And partially remains untouched methane. Along the way, carbon dioxide appears. The excess water is still coming. The process is endothermic, that is, with the absorption of heat. Gradually start to apply air. This procedure will last for 40-50 minutes. While the heat exchangers warm up, the wick will burn with variable force. The conversion produces heat. Then the process will go on, he begins to swing himself. I specially wrote - where there is a heat release, where - absorption.

Question: What is the expected service life of such an installation?

Answer: Installation will work for a long time, so the catalyst service life will limit continuous operation.

Here much depends on the contamination of the gas, on the properties of the catalyst.

If there is a lot of sulfur in the gas, sulfuric acid can form, it is aggressive at high temperatures.

I apologize for the change in the parameters of the tubes for the refrigerator.

The first numbers mentioned that they are thick-walled,

Question: Is the use of two heat exchangers justified? Is it possible to manage one?

Answer: That is, do not heat up to the dispersant ? Then you will spend excess heat, excess electricity.

Question: But there will be one heat exchanger.

Answer: In order to evaporation, you must constantly bring heat. It is necessary that the water is in a certain ratio. Humidity greater than 100% can not be achieved. But at 100% humidity, the amount of water at different temperatures is different. The higher the temperature, the less moisture at the same humidity percentage (? J). The dispersant can create 100% humidity in the air bubble. But in order for this moisture to have a certain amount of water in grams per cubic meter of gas, a certain temperature is also needed. You need to maintain 80-90oC and adjust the water temperature, which is in the dispersant . Depending on this adjustment, you will have different amounts of water per cubic meter of gas. And our formula stipulates this ratio.

Question: The pressure valve is self-made. Can you use KIPovsky , needle?

Answer: You can. It's absolutely safe here. If the pressure in the system becomes more than the pressure with which the ball presses the spring, then the ball is squeezed out and the excess gas is discharged.

Question: Then what pressure should be?

Answer: And then you look. At you, in principle, the compressor of the refrigerator develops pressure up to 2.5 atm. You, in all likelihood, will need 1-2 atm. But you do not need to put a manometer. You just adjust by the wick.

Question: How to insulate the upper chamber of the converter?

Answer: It must be insulated from the outside. They are very many different thermal insulation, it's just that we once learned how to make them from the usual silicate office glue. It can withstand temperatures up to 15000 ° C.

Question: Is it possible to put the converter-reactor close to the installation?

Answer: No.

The distance should be 3-

Question: In the converter-reactor, we have a height

Answer: The mixing chamber and storage chamber must be

Q: The diameter of the outlet?

Answer: This chimney has you.

Here the 50-

Question: Here it is purely schematically shown - the discharge of methanol from below. And if in a can ...

Answer: No, you can not.

Question: ... if the tube to the bottom is ...

Answer: If the tube to the bottom is - you can. It is important not to pour methanol from above.

Question: In the reactor, what is the size of the catalyst particles, since the size of the grid cell depends on this?

Answer: 0.05 -

Question: Are we doing the right thing by designing fittings at the outlet and inlet of the reactor, meaning that the reactor connections to other units of the installation are carried out by stainless tubes?

Answer: The fittings are shown conditionally. The tubes are welded.

Question: What is the fundamental need for compressors from refrigerators?

Answer: In their durability, reliability, noiselessness, accessibility.

Question: What pressure should a sealed canister withstand?

Answer: There is no pressure in the canister.

Methanol as a substitute for gasoline

The advice and experience of practitioners who made installations and driving methanol

Gennady Ivanovich Fedan , a mechanic, an inventor, he has many of his developments. His special passion is the car. He is a mining engineer, graduate of the Donetsk Polytechnic University. Working at one time as a speedway service mechanic , he got acquainted with the use of methanol.

About eight years ago we started using methanol in the car. In the course of the first two years, we fought corrosion. A condensate of water formed, it was necessary to somehow neutralize it. In general, corrosion affected the piston system. In Zaporozhets the engine itself is cast iron, and the carburetor is duralumin. The piston system is steel. Corrosion of the valve, seat of valves was exposed. We tried to add castor oil. It significantly increases the compression. Air modelers, for example, use methanol, adding 15% castor oil. But there is a lot of corrosion: after each use of this mixture, you should wash everything.

We were saved from this by the addition of aviation oil.

On

I must say that methanol is very attractive in many respects as automobile fuel. With the application of it, the pressure temperature (?) Is significantly reduced. By the way , we have an old engine, worn out in order, and it works perfectly well with methanol. At speeds above the average, it makes sense to add water. In this case, the fuel reserve of the engine is increased. I'm still experimenting with the dosage. I am developing the plant in order to have a dosed water additive depending on the operating mode of the engine. As soon as high speeds go, injection begins.

Let's say for some reason you need to temporarily or permanently switch to gasoline. For these cases, I simplified the adjustment of the main fuel system's jet. The point is that the cross section must be increased for methanol. If you leave the jet as it was for gasoline, then when using methanol, the power will fall. To avoid this, you need to increase the cross section of the jet, and the engine will work fine.

In winter, the engine with methanol starts much easier than on gasoline, literally for a few seconds.

Detonation is not at all.

Another positive thing.

Often it was necessary to help the owners of the "Zhiguli", which formed an ice cork in the fuel path.

This now happens very often.

Sell gasoline, diluted with water.

This can not be determined by eye.

The man bought, filled in - and that's it.

In winter, an ice cork is formed in the fuel system.

We have to disassemble the engine, it's all washed.

Motorists spend on this up to two days.

Meanwhile, it is possible to eliminate the traffic jam just in the course of two hours.

I take

Help for " Metanshchikov "

In the August issue of the newspaper "Auto Revue" for 1991, there was an article "Gasoline factory in the barn."

It says that a unique installation for the production of gasoline was developed by the Novosibirsk Science and Engineering Center " Zeosit ".

It can be placed in a freight trailer and received from

Additions

Hello!

Accidentally in the search engine came across your publication and was very interested in its contents. After a brief introduction, at once the inaccuracies admitted by the author surfaced.

Information about methanol was published in the magazine Priority in N 2,3 for 1991 , and not in Parity, as stated in the article, but the fully prepared project was published (as far as I know). In these numbers there were drawings of the reactor with The electric control circuit and the cooler design, after which Mr. Wax (the author of the article) politely apologized and said that further publication is stopped at the request of the power structures of the USSR and those who want to repeat this setting the field of creativity unlimitedly.

I would be more than happy to get acquainted with this project in more detail (unless it's another soap opera).

I return to the inaccuracies of the article: the catalyst for which the rivers is recommended for the 2nd reactor is not GIAL-16, but GIAP-16 (data on the manufacture of catalysts can be found in the book "Catalyst Technology" edited by IP Mukhlenov et al. ).

It is strictly forbidden to supply water directly from the tap to the reactor. It contains chlorine , which instantly poisons the catalyst of the second reactor, the same applies to the gas, which contains impurities of sulfur and active organic substances.

In my setup, I used distilled water and monoethanolamine gas cleaning , all this gives a good result.

After a more detailed study of your article, there appeared a lot of inaccuracies, which we will consider a little later.

This information is for those who seek to obtain a source, ie. The publication of the magazine "Priority", I personally received the data of the journal number by cash on delivery , sending a request to Mr. M. Oshkva ul.B.Kommunisticheskaya, 44, the editorial office of the magazine "Priority" tel. Edition of 272-62-38, 272-27-72 (this was in 1993). I could throw off my magazines , but about 3 years ago I was asked by them to get acquainted with the article and did not return it. I have only the first issue of the magazine , from where the address and phone are taken. Editorial staff.

Let us now turn to the inaccuracy of the description of the schematic diagram of the apparatus according to the nodes.

1st stage - as it was said earlier, water and gas must be purified , so that catalysts 2 and 6 of the reactors can not be poisoned immediately.

More precisely, the ratio of pairs : ras is as follows: 2: 1. There should not be a return of unreacted products in the 1st stage.

2nd stage - methane conversion starts at t ~ = 400 * C, but at such t the low percentage of converted gas , the most optimal t = 700 * C, it is desirable to control it with a chromel- aluminum thermocouple. The catalyst can be applied GIAP-3, it is easier to fabricate .

Refrigerator 4-I recommend for each step to make your own , this will further facilitate the adjustment and not use a coil for these purposes, it is better to turn to the original source there is a rational grain.

Reactor 6- will better address the source, where the principle of operation of the reactor with the electromagnetic pump is described more clearly and the method of manufacturing the electromagnetic pump is described . The data on the catalytic one can be found in Mukhlenov's book.

After the reactor, in my installation there is a refrigerator and a pressure gauge adjusted to a pressure of 25-35at (the choice of pressure depends on the degree of catalyst wear) . I used 2 compressors for injection of synthesis gas .

Condenser 8- I advise you to make a non-cylindrical shape , and a conical (this is done to reduce the evaporation area of methanol) with a window to control the level of methanol. The reacted products are fed from the top of the cone by means of a tube of 8 mm. The trough is lowered into a conical vessel below the throttling tap of 9 by 10 mm.

Unreacted synthesis gas is withdrawn through a tube of 5 mm. Which is welded into the top of the cone , the exhaust gas is fed through the regulating tap to the nozzle where it is burnt. The level of methanol is maintained at 2/3 of the total height of the vessel.

On this I will conclude a brief analysis of the article. For those who are going to repeat this installation, I strongly advise you to get acquainted with the literature on this subject, and especially with the book edited by I. Gohrakh and others. "Chemistry and Technology of Artificial Liquid Fuels" 1954. Edition (the book is old , but sensible).

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.