EcoTop - Fuel economy and power increase

- START

- EKOTYUNING-KIT

- SuperAquaCar

- Pulse

- UPG-2

- Activator Magnetic

- Fuel Activator

- Water injection (ECOMACS)

- HBO

- NanoVit

- V-Tech box

- EcoTop

- AirWing

- Anticoron AKOR

- Roher

- Ecotuning Oil

- Efficiency plus

- FFI MPG Supplements

- Zero filters (K & N)

- Lambda probe emulator

- Diesel particulate filter emitter

- Emulator of lambda probe and MAF

- Usefulness

- A PHOTO

- BUY & CONTACTS

EcoTop is a device that improves the following characteristics:

- Saving fuel by 15-20%

- Increase in the dynamics of the acceleration by 20-30%

- Reduction of CO in 8-14 times

- Compliance with Euro-2 standards

- EcoTop fits all carburetted cars

A simple and effective method for fuel economy of ICE cars (by 10-15%) has been developed, patented and tested. At the same time, it allows to reduce the toxicity of motor vehicle exhaust gases by dozens of times with the implementation of simple vortex mixing devices.

Motor transport - the main culprit of toxic pollution of the atmosphere in the cities, since it is the road transport of goods and passengers in the cities - the most massive and popular. However, the modern gasoline engine of cars is not only extremely imperfect from the position of ecology, but also primitive in terms of energy performance. He has the efficiency. Only about 20%, And since fuel is not cheap now, and constantly rising in price, this fuel inefficiency of engines becomes a real ruin not only for car owners, but for all of us. After all, the cost of expensive trucking of goods and passengers is our daily expenses ..

Despite a significant number of patents, developments in the field of fuel economy and reduction of toxicity of exhaust gases, the modern car is still far from energy and ecological perfection. And the ecology of our vehicles is so bad that it has already created an acute environmental situation of atmospheric pollution of virtually all cities. But for a number of reasons the factories - manufacturers of automotive engines are in no hurry to improve them. And motor transport still literally ruins all of us because of its extreme imperfection. And still for this fuel "gluttony" cars have to pay to us, ordinary citizens. But there is a simple solution to all problems - EcoTop. All information about EcoTop is collected below.

Various methods and devices for fuel economy of petrol internal combustion engines are known. These include methods and devices for fuel and oxidizer activation, turbo boost, electronic dosage systems and electromagnetic fuel injectors, injectors, powerful electric ignition systems, various homogenizers for improving the formation of mixtures, and others. However, the vast majority of these innovations and developments do not allow to significantly increase the fuel efficiency of the gasoline engine.

In addition, because of the complexity of technical solutions, many of these analogues are expensive to implement and therefore never reached mass production

Therefore, taking into account the urgency of this problem and the Russian difficulties in financing science and implementing new developments, we need just a simple "oak" purely Russian solution to this problem.

2. MAIN STAGES OF CREATION AND FORMATION OF ECOTOPE

Vortex device fuel economy of a carburetor engine (abbreviated "ECOTOP") was first proposed and patented in 1998. It consists of a body, vortex nozzles inserted into the body, air filter and air regulator. Later in 1999, the first versions of operating devices of this type were produced: a vortex mixing device for fuel assemblies. At the same time, tests were carried out on the carburetor gasoline engine of the VAZ 2106 vehicle. Experimental studies of one of the first variants of the vortex mixture improvement device carried out on test Stands, and at real driving of the car on a city at once have shown essential economy of fuel of the petrol engine. This fuel economy is most significant on motor modes close to idling, and is about 40-50%. The experiments also showed that the device also provides both fuel economy and reduced exhaust gas toxicity. Moreover, in all dynamic modes of ICE. After all, the vortex of the fuel-air mixture of fuel assemblies in the intake duct of the ICE from the "Ecotope" is formed not only on the hydraulic system, but also when the two carburetor dampers are opened. The beneficial ecological effect of the multiple reduction of toxic carbon monoxide in the exhaust gases of the motor -10 times.) Depending on the mode of operation of the motor. Certification tests of such devices "Econom" in Samara and "Ekotop" in the leading research automotive mechanics institute (NAMI, Moscow) in general have also confirmed its fuel and environmental efficiency in all modes of operation of the automotive engine. Tests of these vortex mixers FA were carried out on gasoline engines of VAZ cars in idle and urban cycle modes on modern test benches. On the device "Ecotope" the State Standard of Russia issued to the firm-developer ZAO "Nitron" the certificate of conformity № РОСС RU.МТ14.В09304, developed and approved the technical specifications TU 4591-001-56647860-2002

3. WHAT IS THE PHYSICAL ESSENCE OF ECOTOPE WORK?

At the heart of this already patented simple aerodynamic design of development lies the vortex formation in the internal combustion engine. And our previously patented invention of vortex inclined mixing and simultaneously controlled depletion of fuel-air mixture (TVS.) The effect of extremely fine crushing and homogenization of fuel is achievable only for certain parameters and direction of the vortex And at a certain dose of additional atmospheric air supplied to the intake path of the motor from the atmosphere. It is in this case that the fuel assembly is best homogenized and burns in the combustion chambers of the ICE in the most complete way. The device "Ekotop" effectively improves the performance of the engine in almost all its modes, especially strongly in dynamic modes.

4. DESCRIPTION OF THE SIMPLEST ESTHOTIC DESIGN

Structurally, the Ekotop device is quite simple and represents a relatively thin vortex mechanical spacer with an original aerodynamic profile that not only does not increase the aerodynamic drag of the intake tract, but, on the contrary, reduces it due to the emerging vortex. Which is installed under the regular production car carburetor. This spacer is in essence an effective aerodynamic swirler of the fuel-air mixture (TVS) and consists of only three main parts - a body and two rings-air nozzles inserted in its housing. The spacer has in the body special calibrated sloping openings for communicating with the atmosphere and the intake path of the motor Creating an optimal atmospheric vortex in the motor. The design of the filter was further simplified further, which reduced the cost of the product to 100 r. And even lower when using the standard elements of this simple design.

5. CRUSHING AND MIXING THE CROWD

In this mode, thanks to "Ekotop", the maximum fragmentation of fuel particles occurs, a complete breakdown of the fuel film from the internal walls of the intake tract and many other interesting and useful effects in the cycle of preparation and combustion of FA in the motor. As you know, environmental and many other parameters of all gasoline engines are the worst on h.x. Our invention provides, in this previously problematic environmental regime, a significant reduction in the toxicity of exhaust gases (VG) of an internal combustion engine. Experiments have shown the efficiency of mixture formation and deeper combustion of fuel assemblies. In the test reports of the "Ecotope" on serial internal combustion engines, in particular, the increase in engine idle speed (hh) from 900 rpm to 1400-1600 rpm is recorded. This effect experimentally confirms the effective improvement of the quality of the combustion fuel mixture of a homogenized lean fuel assembly.

6. Efficiency of fuel economy

The efficiency of the fuel economy of a particular motor of motor vehicles largely depends on the correct one-time adjustment of the combustion engine carburetor after installing the "Ecotop" in the motor of our device. Indeed, the viral rotation of the fuel mixture is transferred to the motor itself, and therefore, the "Ecotop" increases the efficiency of combustion of fuel assemblies in combustion chambers. Therefore, the speed of the motor x.x initially increases sufficiently (by 300-400rpm) .. After re-adjusting the carburetor with the "Ecotope" - again to the base speed of 900 rpm, we achieve the fuel economy effect-reducing the fuel consumption by a screw of quality x. X. Carburetor. The fuel consumption of the engine VAZ 2106 on h.x. Is halved. Simultaneously with the improvement of the completeness of combustion of such a treated fuel assembly, the toxicity of the VGD IC decreases drastically. So carbon monoxide when installed in the motor of the vortex device "Ekotop" decreased in the SH by 10-15 times, and all the others, for example, hydrocarbons were reduced by 30-40% .. Moreover, experiments showed a decrease in fuel consumption and toxic components in the VGD engine Only on HP, but also in other modes of operation of ICE.

7. MODERNIZATION OF VORTEX HOMOGENIZERS OF ECOTOP TYPE

In the process of developing the "Ecotop" device, a great deal of design and survey and experimental work was done. In particular, the original design of the TVS swirler has been dramatically simplified, one of its simplest versions has also patented a single-hull design, optimal diameters and slopes of the swirl holes in the body and in the nozzle rings, the material of the structural elements has been selected for thermal and mechanical characteristics

8. EXPERIMENTS AND CALCULATIONS

Experiments and calculations have shown the dependence of the stability of the engine at idle and in the modes of a small gas together with this swirler, on the velocity of the vortex and on the angle of inclination of the vortex flow to the normal of the carburettor .. Elements of the swirler providing the optimal velocity of the vortex, The inclination of the vortex inlet into the combustion engine inlet. In the process of experiments and debugging of the device "Ecotope", the essential role of the primary tuning of the carburetor and the degree of enrichment of the fuel mixture produced by the carburetor was also revealed ... As is known, the most common mode of tuning carburetors, especially worn out motors, for some re-enrichment of fuel assemblies. The need for such tuning of a worn carburetor is due to the need for a stable starter motor start, especially in the winter. It is with this soma common adjustment of carburetors, the fuel economy effect from the use of the vortex device "Ekotop" is maximal and reaches about 15-20% in the Moscow city cycle (idle time up to 30%) ... In the case of the optimal initial setting of the unearned carburetor, the effect of economy Fuel in the installation of the "Ecotope" on the motor is slightly lower, but still the effect of environmental cleaning of the VG DVE remains.

9. EXAMPLE OF THE PRACTICAL IMPLEMENTATION OF THE INVENTION

Let's consider in more detail the work of the developed device for vortex mixture formation "ECOTOPE". The device works on gasoline carburetor ICE as follows. When starting the engine of the engine in the intake manifold creates an air discharge, under the action of which from the jet nozzle fuel flows and is crushed in the main airflow. However, due to the almost completely closed throttle valve of the carburetor. In this mode of operation of the engine, the fuel mixture is usually re-enriched, and mixed poorly with air. So it is the poor quality of fuel assemblies in this mode of operation of the motor that leads to over-consumption of fuel and to an increase in the toxicity of the VG DVS. When installing the "Ecotop" on the motor for its carburetor, the operation of the fuel assembly system of the engine slightly changes. Namely, in the idle mode of the motor, in its intake path through the tangential openings of our spacer below the throttle valve, an additional air flow from the atmosphere, dosed and swirled in the aerodynamic profile of this device, arrives. As a result, this vortex twists the main flow of fuel assemblies and finely divides the droplets of fuel. In addition, due to the optimal inclination of the inlet of this vortex in the intake path, it tears off the fuel film from the inner walls of the intake path of the motor and homogenizes it, creating the effect of additional savings and improving the quality of fuel assemblies. Moreover, as shown by experimental studies, this partially created TVS vortex is also transferred to the combustion chambers themselves, improving its combustion quality, and hence the ecology of the motor. Of course, this device provides the greatest effect of improving the quality of fuel assemblies in idle and dynamic modes (with opening and closing of throttle valves), but taking into account the fact that dynamic modes of operation of engines and idle mode of cars in cities (traffic lights, congested urban Routes, and low speeds of motor transport, traffic jams, etc.) occupies 30-40% of the total time of driving cars, the total fuel saving effect from the "Ecotope" is quite large and on average reaches 15-20%. It is necessary to note once again that when installing the device "Ekotop" on the carburetor engine, it is necessary to first adjust the carburetor to the economical mode of operation in connection with the effect of increasing the speed due to the depletion of fuel assemblies and the activation of fuel assemblies by ours with a vortex method

10. ELECTRICAL FAILURE AND INTRODUCTION OF WATER INTO THE INTERNAL INTAKE TRACT

We also carry out further technical upgrades of the proposed method and devices for vortex homogenization of fuel assemblies in order to increase the fuel economy of the engine. In particular, a method of electrifying fuel assembly and water ballasting of a fuel mixture with distilled water vapor is proposed.

A) electrification of fuel assemblies

This becomes technically possible when manufacturing a vortex mixer made of heat-resistant plastic, from triboelectric materials, for example, from fluoroplastic or ebonite. The essence of this effect of electric fuel crushing consists in using for such an electric crushing of powerful Coulomb electrostatic forces repulsing electrically charged fuel droplets from each other with their subsequent fine crushing in the intake tract of the motor. Experiments have shown the possibility of achieving an even more significant effect of homogenization of fuel assemblies in the case of electrostatic crushing of droplets Fuel and electrification of fuel assemblies. As a result, a reduction in fuel consumption and toxicity of the VGD engine by 5-10%

B) production and injection of steam into the combustion chambers of combustion engines

Indeed, the modern thermal engine ICE has an extremely low efficiency. And as a result, huge heat losses (up to 30 kW). So why not use them to produce steam and inject it under pressure into the engine's intake path. And we did it. The economical effect of such a steam engine is quite obvious. After all, with such use of the thermal energy of the ICE, a simple variant of steam turbo-supercharging is obtained in the motor, which allows you to save up to 30-40% of the crowd while maintaining the previous power of the engine.

11. ABOUT THE PHYSICAL ESSENCE OF THE DATA OF INNOVATION

The additional effect of fuel economy of the car is achievable with the addition of a TVS swirler to the fuel assembly in addition to the dosed amount of pure steam or the amount of distilled water in the intake path. The idea of ballasting gasoline with water is not new, However, in our case of turbulent fuel treatment, such a combined method With dilution of fuel with water) has a number of new advantages. The fact is that the depletion of fuel assemblies results in a certain increase in the combustion temperature of the mixture in the models of combustion of the motor. And with improper adjustment of the "Ecotop" device to a too lean mixture there is a potential danger of overheating of the engine during the burning of lean fuel assemblies. And the appearance in the process of this burning of toxic nitric oxide. A dosed introduction of steam or water into the intake duct of the internal combustion engine and the active mixing of their vortex with the rest of the fuel assembly just allows programmatically to lower the combustion temperature of the lean fuel assembly in the combustion chambers to an optimum level of 1000 degrees Celsius, and thereby limit or eliminate the combustion temperature effect Eliminate the occurrence of nitric oxide in the exhaust gases of combustion engines.

12. CONCLUSIONS

- 1 vortex device "Ecotop" for today the most effective and simple means for reducing fuel consumption and toxicity of VG DVS of all types and types of carburetor motor vehicles

- 2 Guaranteed fuel economy of the engine when installing the Ecotope in urban mode 10-15%, depending on the degree of wear and tear of the motor and driving characteristics in the city cycle. (Seasons, topography and population density, etc.)

- 3 The payback period of the device is 1-2 months.

SUMMARY

The present development of the vortex homogenizer "Ekotop" has been approved, certified and already mastered in series production.

As shown by the tests, it is effective for reducing fuel consumption, and the toxicity of VGD DVS, extremely simple to set up and operate, maintenance-free (filter replacement). The device is applicable on all models of VAZ and GAZ vehicles with carburetor internal combustion engines, including gazelle and sable vehicles. The greatest effect of fuel economy the device gives in rear-wheel drive vehicles with carburetor Ozone. According to our estimation, the "Economy" device pays off due to fuel economy on the VAZ 06 vehicle in almost 1-2 months. According to this development, "Econom" has patents, a certificate of compliance, a full package of technical documentation and promotional materials. The creative development of this device allows to expand the number of useful functions of the device, increase its fuel efficiency and the effect of environmental cleaning of the VG DVS. With a small technical revision, this device can be used and with in petrol injectors. Such experimental studies are currently being carried out by the authors of the development. To further improve this useful device and more effectively promote it across Russia and the CIS, it is advisable to cooperate with our interested firms and organizations.

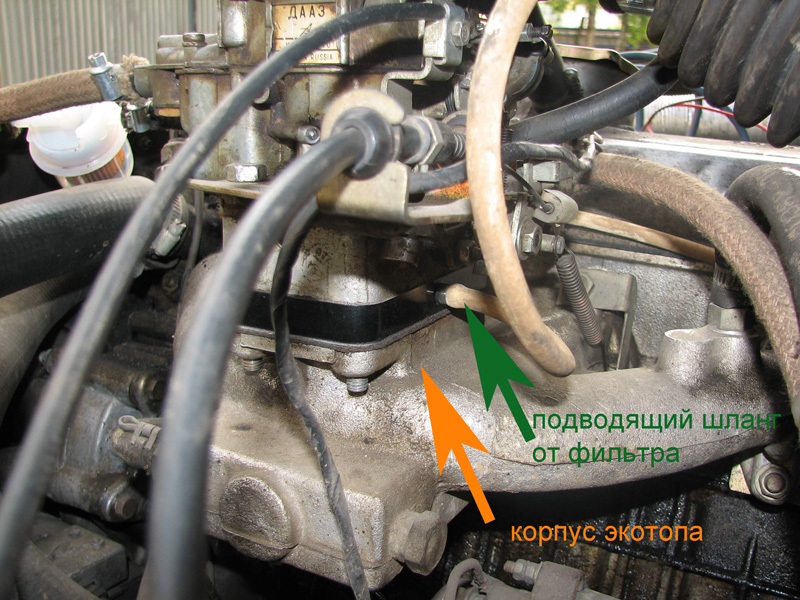

PHOTO OF SERIES SAMPLE ECOTOP

Vortex Ecotope in full set (with a hose and a regular filter at the end - a fine gasoline filter was used as its filter)

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.