NanoVit Motor Renovator

- START

- EKOTYUNING-KIT

- SuperAquaCar

- Pulse

- UPG-2

- Activator Magnetic

- Fuel Activator

- Water injection (ECOMACS)

- HBO

- NanoVit

- V-Tech box

- EcoTop

- AirWing

- Anticoron AKOR

- Roher

- Ecotuning Oil

- Efficiency plus

- FFI MPG Supplements

- Zero filters (K & N)

- Lambda probe emulator

- Diesel particulate filter emitter

- Emulator of lambda probe and MAF

- Usefulness

- A PHOTO

- BUY & CONTACTS

NANOVIT - WINNER OF THE 2008 INNOVATION COMPETITION FOR THE GERMAN AUTOMOBILE INDUSTRY!

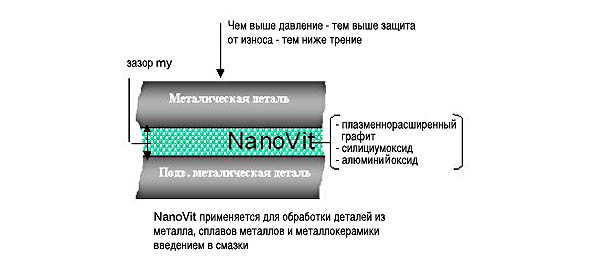

NanoVit Motor-Renovator - a product of nanotechnology, is a mixture of silicon dioxide, aluminum trioxide and plasma-expanded graphite

Preserves its lubricating properties up to 1200 ° C.

The thickness of compensated wear is from 0.0001 to 0.1 mm.

Reducing the friction coefficient to 0.0001.

The use of nanotechnology to reduce friction losses in engines and other aggregates makes it possible to realize a new principle of extending the life of kinematic friction pairs through micromodification of friction surfaces in the process of machines and mechanisms using friction energy. The introduction of NanoVit into friction zones leads to the active construction, using friction energy, of nanocrystalline structures in the form of a self-healing micromodified layer on the metal surface. On the metal surface, the micromodified layer is a strong and elastic structure, the surface part of which is dynamically destroyed and restored, remaining in a certain equilibrium. The micro-modified layer can be adjusted by the amount of the product. The large friction force and high temperature repeatedly increase the activity of NanoVit in modifying the surface layer.

Economic effects:

- Fuel economy 10-25%

- Savings of lubricants and oils 3-5 times

- Extend the service life of parts 2-5 times

Results of application:

- Compression recovery

- Oil Pressure Restoration

- Reducing wear of friction parts of the engine

- Increase the engine power (by reducing friction losses, restoring the geometry of rubbing surfaces, restoring the compression)

- Noise reduction

- Reduction of toxicity

- Processing is performed 1 time for the entire life of the engine

How does NanoVit-Motor-Renovator work?

The processing process can be divided into two stages. At the first stage, there is a thorough cleaning of surfaces from wear products, carbon deposits and other contaminants.

Further, the multilayer coating is synthesized on the prepared and cleaned surfaces of the friction pairs. First, due to the formation of the coating, an increase in the area of the highly stressed friction zones occurs, and then the coating extends to all rubbing surfaces, depending on the magnitude of the contact loads applied to them, restoring the geometry of the rubbing surfaces.

During the formation of the multilayer coating, the temperature in the friction zones decreases, and the growth in the thickness of the coating slows down until its complete cessation. Thus, self-regulation of the thickness of the protective layer takes place.

The synthesized surface consists of three layers:

- The first is a reduced layer, which has a common crystal lattice with a metal of friction parts;

- Second - an intermediate, elastic layer;

- Third - an external, protective layer with a low coefficient of friction and high abrasion resistance

The resulting multilayer coating has a high microhardness and elasticity.

Characterized by protective properties against electrochemical corrosion.

This surface is capable of regeneration and operates under frictional conditions, like a protective layer.

Areas of administration:

- Oils and lubrication systems in automotive engines

- In all traction engines on ships and railway locomotives

- For all parts from metals, metal alloys and cermets, working with all types of lubrication

- As an additive to oils

Economic effects:

- Decrease in material costs

- Reduced maintenance and maintenance costs

- Reduced repair time and downtime

- Reducing the cost of spare parts

Operational and technical effects:

- Improved parts surfaces

- Reduction of loads in power units

- Increased wear protection and continuous protection

- Increased service life of aggregates

- Noise reduction

- Elimination of defects on friction surfaces

- Preservation of oil properties

- Protection against electrochemical corrosion

Fields of industrial application

The product is used with a positive effect in all technical devices that realize mechanical movements of parts and have lubrication systems from simple to technically perfect. In all cases, the internal mechanical losses and the wear rate of the mating parts decrease, the temperature of the lubricating oil decreases.

Machine building, automotive, shipbuilding, power equipment, agricultural machinery, road machinery, wind power, rolling mills, etc. (Gearboxes, bearings, gasoline internal combustion engines, diesel engines-automobile, diesel, ship, transmission, electric motors, turbine generators, compressors, hydraulic systems, etc.)

The consumer of the product always gets a real economic and ecological effect.

The consumption of fuel and lubricants is reduced, the emission of pollutants into the environment is reduced, the service life of the equipment is extended, the costs for current and capital repairs are reduced.

The application procedure is technically simple, does not require the stoppage of equipment and is carried out during its operation. The product is compatible with any oils.

Practical application of the product on motor transport, sea vessels, diesel locomotives, quarry equipment, bulldozers, excavators, tractors and agricultural combines has fully confirmed the effectiveness and economic feasibility of using the product.

Manufacturer: "MSH Mineralstoffhandel GmbH" Germany.

Certification tests: TUV-Thuringia.

|

NanoVit-Motor Renovator for internal combustion engine up to 2.0 liters with an oil volume of up to 5 liters. For complex engine treatment. 2 bottles * 150 ml. |

|

It is designed for working volume of the engine up to 2 liters and the volume of oil to be filled up to 5 liters and is also used for refilling. * 1 bottle of 150 ml. |

|

NanoVit-Motor-Renovator for the ICE of trucks with an oil volume of up to 40 liters. 2 bottles * 250 ml. |

|

NanoVit-Motor-Renovator for the ICE of trucks with an oil volume of up to 20 liters, also used for refilling. * 1 bottle of 250 ml. |

|

NanoVit-Getriebe-Renovator for manual transmission / differential / bridge with oil volume up to 20 liters. * 1 bottle of 250 ml. |

|

NanoVit-Getriebe-Renovator - Renovator for automatic transmission with oil volume up to 20 liters. * 1 bottle of 250 ml. |

|

NanoVit-Truck-Service kit - kit for complex processing of trucks with manual transmission 2xMotorrenovator (for ICE) 2xGetrieberenovator (for manual gearbox / differential / axle). 2 bottles * 250 ml. |

|

NanoVit-Truck-Service kit-kit for trucks with automatic transmission 2xMotorrenovator (for ICE) 1xGetrieberenovatorfor 1xGetrieberenovator (for differential / bridge). 2 bottles * 250 ml. |

|

For prom. Consumers offer a concentrated order |

For the engine

The product is a specially prepared mixture of nanopowders (14-16 nm) of silicon dioxide, aluminum trioxide and plasma activated graphite, which does not change its structure at temperatures up to 1200 ° C. This mixture is made on the basis of a unique activation method for each component that allows the creation of friction parts of engines in the process Their work antifriction coating with a long-lasting effect of non-wear and low coefficient of friction. This coating is created in the process of friction of the metal surfaces of engine parts and represents a dynamic equilibrium structure that reduces friction and wear and extends the life of the engines. NanoVit ® does not change the composition of lubricating oils and is compatible with any oils. NanoVit ® also works after changing the oil.

Range:

Set 2 * 150ml (for engines with engine capacity up to 2.5 liters and the volume of oil poured into the engine to 5 liters)

Set 2 * 250ml (for the engine with a volume of oil poured into the engine to 40 liters)

Single bottles of the indicated volumes are also offered.

The order of application:

The treatment consists of two stages, the product is poured into the oil filler of the engine.

First step: Shake the first bottle until the sediment dissolves on the bottom. After that, pour the contents of the bottle into the oil filler neck. 5-10 minutes the engine should run at idle. Drive at least 150 - 200 km

Second stage: After 150 - 200 km of traffic. Always replace the oil filter! Oil change is not necessary. Shake the second bottle thoroughly before dissolving the sediment on the bottom. After that, pour the contents of the bottle into the oil filler neck. The engine should idle for 3 minutes.

For gearbox and transmission

Getriebe-Renovator NanoVit ® provides long-term protection against wear of all types of transmissions, as well as differentials and bearings. Active components form on the surfaces of rubbing parts of gearboxes, a durable and elastic antifriction layer with a lasting effect. This coating is created during the friction of the metal surfaces of the gearbox parts and is a dynamically balanced structure that reduces friction and wear and extends the life of the gearbox. NanoVit ® does not change the composition of lubricating oils and is compatible with any oils.

Getriebe-Renovator NanoVit ® is a transmission oil with active ingredients incorporated into it. It is introduced into oil located in gearboxes, differentials and bearings. Devices and their parts must be in good order.

Getriebe-Renovator NanoVit ® can be obtained for all kinds of gearboxes in different volumes of concentrate.

The order of application:

Before use, vigorously shake the bottle until the sediment dissolves at the bottom. Pour into warm oil and drive by car for at least 10 minutes. Oil change in the device is not required.

Product action: Getriebe-Renovator NanoVit ® forms a strong and elastic protective layer that - has the properties of self-regulation when changing loads: stable and continuously restored with a low friction coefficient in nanocrystalline form.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.