| section Home

Production, Amateur Radio amateurs Model aircraft, rocket- Useful, entertaining |

Stealth master

Electronics Physics Technologies invention |

space Mystery

Earth Mysteries Secrets of the Ocean Stealth section Map |

|

| Use of material is permitted for reference (for websites - hyperlinks) | |||

TECHNOLOGY OF MICROWAVE

![]()

Guriev Alexey

See also: |

All equipment for microfiche consists of a flask, a centrifuge is also a burner.

Opoka is a piece of pipe with a wall thickness of 2-3 mm . It is necessary to prepare several flasks of different diameters for models of different sizes. The essence of the condition is that the largest mold can fit freely on the centrifuge stand.

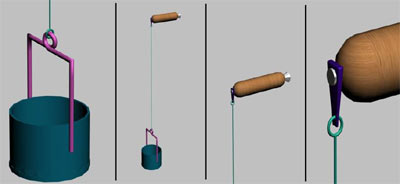

Manufacture of a centrifuge. Put a metal rod with a diameter of 5-6 mm into the wooden handle. An earring is fixed to the rod. The rod should rotate freely in the handle. The stand for the flask is made of metal (in my case it is also made of galvanized steel). Its diameter is 7-8 cm , the height of the rim is 2.5-3 cm . To the side, rivet the bracket 11-12 cm high from the base of the stand. At the top of the brace make a twisted ring. The clamp is connected to the earring by a wire yoke with bent rings at the ends. The length of the rocker is 25-30 cm , the diameter is 4 mm .

|

|

Alloy for casting - 64% copper, 32% zinc, 3% tin, 1% lead. It is not necessary to adhere to the exact proportions. In extreme cases, it is possible to use molten "copper" coins (old fines). The material for the model is wax, for the form - gypsum, alabaster, cement mixes (fine-screened), talcum powder or pumice powder.

Burners can be used any, if only the temperature of the flame could reach about 1100 degrees.

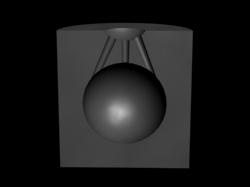

When making a model of wax, carefully trim its surface, otherwise the metal will repeat all the flaws of the model. To the model, attach the metal sprue pins with wax. A benign pin is obtained from a sewing needle with a broken point. The pins are attached to the model closer to the edges and also set them so that they converge at one point. Considering the dimensions of the model, select the bead so that the distance between the bottom is also a model, only it seems that between the model and the top of the molding mass there was at least 1 cm .

Molding mass, prepare from 2 elements of gypsum, one element of talc or pumice (I advise you to experiment with different mixtures to get the best results). Mix the mixture well into the water. The mass should have the consistency of a thin sour cream. Put the flask on the asbestos sheet also fill with the mixture. While the mass does not solidify, take the model for the pins and also immerse it in it, slightly vibrating to remove air bubbles. After half an hour, cut the gate bowl, carefully remove the pins. The runner channels must be located in the center of the bowl, each with an independent outlet (see the figure above). Place the dipper in the oven gutter channels downwards and within a couple of hours, gradually increase the temperature to 350 degrees . Later, put the flask on the side of the flue on the gas stove to burn off the remaining wax. Firing to produce before the reddening of the walls of the flask. At the same time, transfer the flask to the centrifuge, insert the desired number of metal, a bit of borax into the spout cup. Melt the metal with a torch, start hastily rotating the centrifuge (due to the centrifugal force, the necessary pressure is created to penetrate the metal into the mold). Twenty revolutions are sufficient for the filled filling of the mold, the crystallization of the metal. To extract the casting hot casting must be put under a stream of water. Casting the casting in a 15% solution of sulfuric acid.

Guriev Alexey

Comments

Commenting, keep in mind that the content and the tone of your messages can hurt the feelings of real people, show respect and tolerance to his interlocutors, even if you do not share their opinion, your behavior in terms of freedom of speech and anonymity offered by the Internet, is changing not only virtual, but real world. All comments are hidden from the index, spam is controlled.