About Chip Tuning

Chip tuning is the optimization of the engine management program in order to increase its power. The engines of most modern cars are equipped with electronic control units (ECU-Engine Control Unit), in which there is a chip-memory chip. This means that the operation of the engine is controlled by electronics using the software programmed into it. It generates control signals for the fuel supply, ignition and turbo systems.

That is, the most important characteristics and characteristics of the engine can be changed by modifying the engine management program. The initial factory program of the engine is changed to tuned. However, it must be noted that the manufacturer's warranty for the engine that has been subjected to the tuning is not covered. The main characteristics that can be improved are power, torque and "acceleration".

Each engine has a microprocessor. The program of its work is directly a program of data processing (software) and one-two-three-dimensional calibrations (tables with data). The calibrations are different for different operating modes of the engine (start, economical, power, XX, transient) and switch depending on the mode. Almost all tuning versions of the firmware have modernized the modes of cold start, stroke, maximum permissible engine speed and vehicle speed, change the ignition timing setting, the injection time, replace or even turn off the systems that control the level of exhaust toxicity. The increase in engine power can be 5-10 percent, except for the supercharged engines, where the power can increase by 20% or even more.

Advantages of the chip tuning

On a track with intensive movement, there is more opportunity to accelerate in overtaking-High traction and speed characteristics - it's easier to drive a car in the city

-Many faster and cheaper compared to engine forcing

-Easy to drive when the car is full

In favor of chip tuning says the fact that the tuning car sharply increases the elasticity of the engine and the torque, that is, when you suddenly press the accelerator pedal the engine will pick up at a lower speed - you get a greater intensity of acceleration. For engine tuning, monoinjection engines, as well as some engines with the KE-Jetronic injection system, are not suitable.

How is the chip tuning done

To begin with, it is necessary to diagnose all engine systems so that malfunctions do not affect the final result. It is also necessary to find out whether it is possible to change the parameters of the electronic control units on your engine. If everything is in order, then go ahead. The ECU is removed from the car and the software is read from it. We are interested in parameter tables. We need to change their values in such a way to get higher values than in the standard program. To modify the programs, you need to work with the ignition timing tables, the injection duration and the boost pressure limitation. In general, the program for managing a modern car has up to 100 tables, and only 10-20 of them can be changed to increase power and traction. For cars of each brand and model, these tables are purely individual and if you simply transfer them to another ECU you will be completely disappointed - the engine just will not start.The cost of high-quality tuning engine ranges from 300 to 600 dollars.

Chip-tuning for beginners

Introduction The word "tuning" means "adjustment", "adjustment", "tuning".

However, this is not just an increase in power, it is an increase in the overall performance to match a specific user. It happens that following the desire to make a certain tuning of their car people go to the auto-tuning store, being mistaken in their idea of the need for this or that detail. In this case, in order to satisfy the client's needs, for the correct choice of the details, he must first determine what is necessary and for what exactly. First, let's give an explanation of the so-called "easy" tuning.

The overall increase in the performance of the car, in its correct interpretation by the user, is the observance of the main condition of "safety", which includes, among other things, the balance of concepts such as "driving", "turning", "stopping". Often, for example, there are cases when, after increasing the engine's power, there is a certain discomfort and uncertainty during braking. There is a feeling that the brake started to work worse, although before that, there were no complaints against him. Naturally, because of this, confidence on the road is lost. Due to the increase in engine power, the wheels begin to slip along the asphalt - "polished". Hence, the efficiency of transferring engine power to the road is low, because of what deteriorates such operational performance of the car as stability in driving. The quality of acceleration has increased, and the corresponding deceleration leaves much to be desired. There are a lot of such examples, when tuning is subjected to a certain operational quality, and the overall balance in operation is absent, thereby causing complete concern to the user. It is also necessary to balance not only the entire car as a whole, but also individual qualities of driving, turning and braking. Sometimes, when the engine power is increased, the power is increased at high rpm, and the power at low and medium revs remains the same. At the same time, the user feels that the effect of the done procedure for increasing the engine power is somehow lost. In addition to the above inconveniences, it can be worse when installing any part of the tuning during operation leads to the breakdown of other, innocent "native" details. Obviously, it is necessary to think about maintaining a balance when tuning your car.

Thus, the initial value of tuning, like balance, is important in its interpretation as adjustment, adjustment, tuning.

1. DEVICE OF THE ENGINE.

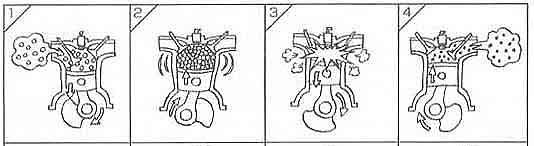

1) Drawing in air, mixing it with fuel (drawing in, mixing) .

2) The air drawn in from outside and the fuel (air-fuel mixture) are compressed under pressure ( compression ) .

3) The compressed mixture ignites from a spark (ignition) , an explosion occurs.

4) Burning gas (exhaust gas) is output (exhaust) .

And so there is a cyclical repetition.

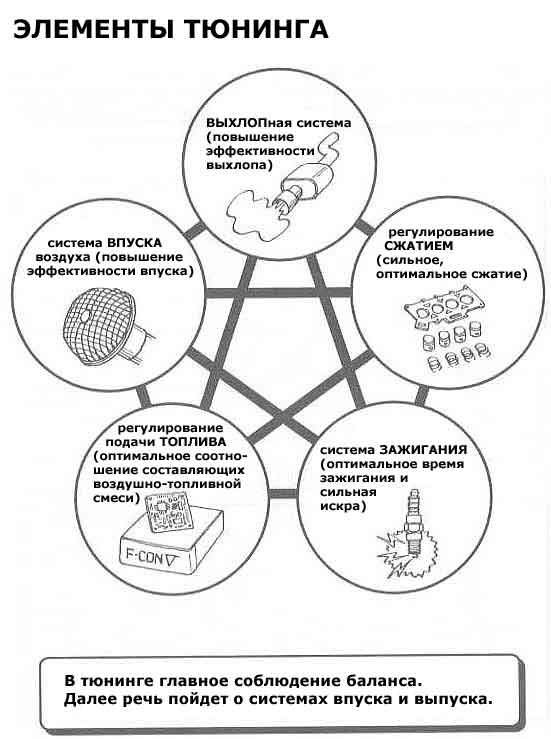

It is believed that for the engine the most important are three points, namely: compression, air-fuel mixture, ignition. In this case, tuning (increasing the efficiency of ignition of the fuel-air mixture) is an intensification of these factors, bringing their state to optimum. There are two main directions for strengthening these factors, which are inherently different. These are positive directional methods that enhance the above processes, and methods of negative orientation, designed to reduce the losses with which these processes are accompanied. Tuning, designed to reduce losses, is to reduce the load on the engine itself (without any side effect), resulting in increased power. The procedure for such tuning is to get rid of objects or parts that are a burden, or to change their shape (kind) in order to minimize their negative impact.

An example of tuning.

As the amount of compressed air and the force of its compression increase, the explosive

As the amount of compressed air and the force of its compression increase, the explosive

As the amount of compressed air and the force of its compression increase, the explosive force will also increase, and, accordingly, the output power also increases. Obviously, the more air is sucked into a certain engine, the more power to compress this engine should possess.

An example of tuning.

In the process of connecting the drawn-in air and the corresponding amount of fuel, a certain ratio of the components of the air-fuel mixture formed during compression is required, which will ensure its easiest ignition to increase the explosive force and, correspondingly, the output power of the engine. This process of adjusting the supply of the fuel connected to the air is also called: fuel regulation.

In the process of connecting the drawn-in air and the corresponding amount of fuel, a certain ratio of the components of the air-fuel mixture formed during compression is required, which will ensure its easiest ignition to increase the explosive force and, correspondingly, the output power of the engine. This process of adjusting the supply of the fuel connected to the air is also called: fuel regulation.

An example of tuning.

Another important point is time, more precisely the time interval in which the compressed air-fuel mixture is ignited. With the optimal timing of the ignition of the air-fuel mixture, during which it will be thoroughly and completely ignited, the greatest explosion force and, as a result, the greatest output power will also be provided.

Another important point is time, more precisely the time interval in which the compressed air-fuel mixture is ignited. With the optimal timing of the ignition of the air-fuel mixture, during which it will be thoroughly and completely ignited, the greatest explosion force and, as a result, the greatest output power will also be provided.

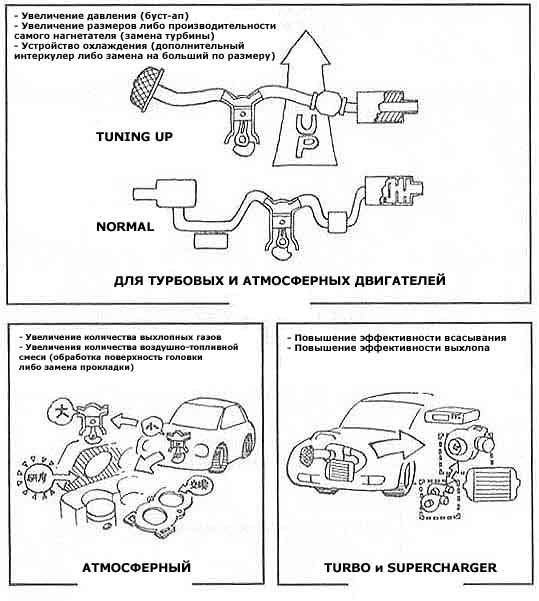

AIR INLET AND EXHAUST SYSTEM.

1. AIR INTAKE SYSTEM.

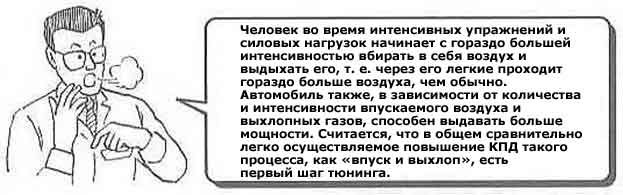

To increase the efficiency of the air intake system, if possible, all objects that create resistance to the air flow must be eliminated for the most unobstructed intake of air into the engine. Whatever it was, the tuning of the air intake system consists in replacing the air filter. HKS, for example, produces the Super Power Flow line and Super Filter. Conventional standard filters are designed for use in a wide range of conditions, so with prolonged use they lose their properties. And if there are still details, the purpose of which is to reduce the sound when the air is sucked in, then the retraction efficiency drops significantly. Similarly, you can describe a runner-marathon runner wearing a gas mask.

To increase the efficiency of the air intake system, if possible, all objects that create resistance to the air flow must be eliminated for the most unobstructed intake of air into the engine. Whatever it was, the tuning of the air intake system consists in replacing the air filter. HKS, for example, produces the Super Power Flow line and Super Filter. Conventional standard filters are designed for use in a wide range of conditions, so with prolonged use they lose their properties. And if there are still details, the purpose of which is to reduce the sound when the air is sucked in, then the retraction efficiency drops significantly. Similarly, you can describe a runner-marathon runner wearing a gas mask.

Here, replacing the standard conventional filter in its original location (filter box) with a Super Filter filter will undoubtedly affect the efficiency of air retraction. However, the installation of a qualitatively different filter instead of a standard box Super Power Flow, which, in view of its design, is able to draw a much larger volume of air, corresponds to a higher level of tuning. The efficiency of the filter depends largely on the shape of the structure, since air passes through its walls as well. In comparison with a standard filter, in order to maintain the high efficiency of such a filter, it is necessary to withstand exactly the cycle of its replacement, which, by the way, is shorter than that of the usual one. But this is the key to successfully maintaining the filter function.

Here, replacing the standard conventional filter in its original location (filter box) with a Super Filter filter will undoubtedly affect the efficiency of air retraction. However, the installation of a qualitatively different filter instead of a standard box Super Power Flow, which, in view of its design, is able to draw a much larger volume of air, corresponds to a higher level of tuning. The efficiency of the filter depends largely on the shape of the structure, since air passes through its walls as well. In comparison with a standard filter, in order to maintain the high efficiency of such a filter, it is necessary to withstand exactly the cycle of its replacement, which, by the way, is shorter than that of the usual one. But this is the key to successfully maintaining the filter function.

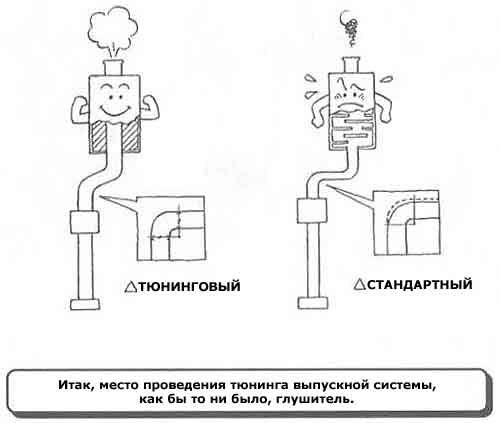

2. EXHAUST GAS SYSTEM

In principle, the prerequisite for tuning the exhaust gas system will be to increase the efficiency of its operation. However, only the elimination of various kinds of resistance in this system, and the increase in the efficiency of its work - are not the same. Removing the exhaust pipe of the muffler, you eliminate the exhaust resistance, but at the same time quality deteriorates the properties of torque and the process of exhaust. Therefore, it is necessary to establish some moderate resistance. A good example is the exhaust manifold, the shape and type of the collective part of which determines the nature of the car. In addition, exhaust fumes and adverse noise effects on the environment are again under certain influence of this element. Therefore, it is necessary to carefully consider all possible consequences when implementing the tuning of the exhaust system. Whatever the case, the place for implementing the tuning of the exhaust system is the replacement of the silencer.

Standard silencers, in view of their form of torsion and cost, rather quickly become unusable from the formation of unnecessary bends and cracks ("hole"). Therefore, as a design designed to highly efficiently provide noise reduction and torque at low speeds, such mufflers look far from the best example. On the contrary, on sports mufflers, the formation of unnecessary bends is a rarity, and cracks are almost not formed, and besides, their design features allow achieving high efficiency. The effect of such a silencer can be compared as a seasoning for foods. The motor of the sports car starts to breathe easier, and for ordinary motorists it is possible to select the appropriate behavior of their "swallows", providing a certain torque. As for the sound, there is also the possibility of selecting a muffler for a certain car so that the driver can feel all the nuances of her behavior. And although the talk about the turbine will be lower, here we can note the following. Because the turbine uses the exhaust energy, it creates resistance for it. Consequently, an increased outlet pressure is necessary. In comparison of cars with a turbine and without a turbine, the importance of the design of a silencer having a minimum resistance is evident. By varying the different forms of the silencer for certain cars, it is possible to increase the discharge pressure, and thus achieve an increase in power.

THE SYSTEM OF THE INJECTION

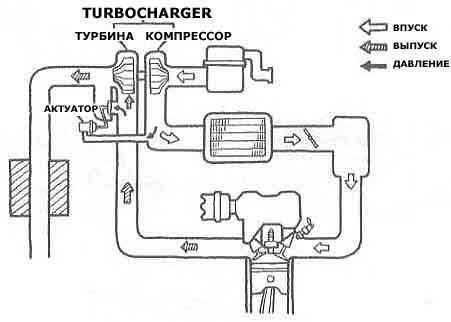

Turbocharger is ...

The energy of the exhaust gases emitted from the engine acts on the turbine blades, which rotates like a mill. A similar mill is a compressor mounted on one axis with a turbine. It also rotates, in full accordance with it, compressing the air and forcibly pumping it into the engine, thereby representing a power-boosting device.

In this case, the volume (pressure) of the injected air is denoted as the discharge pressure, or boost. The exhaust gases entering the turbine regulate the booster by their quantity. Adjustment of the amount of exhaust gas entering the turbine is performed by the so-called cut-off valve, which is located between the turbine and the engine. With its help, some of the gases, before reaching the turbine, are ejected further into the outlet. The operation of the valve itself depends on the pressure of the compressor. Ideally, increasing the boost, you can pump into the engine as much as possible a large amount of air. In fact, the intensity of the engine and the abnormal combustion in its cylinders - the knocking of the engine, or detonation - is a problem limiting the boost. In general, the installation of a certain boost in a conventional machine occurs, proceeding from various conditions and assignments, in the process of their exploitation by motorists, taking into account also strict restrictive norms for exhaust gases.

* The cut-off valve can be in the form of an actuator and in the form of a so-called west -gate (English waste-gate ).

Bust-up is ...

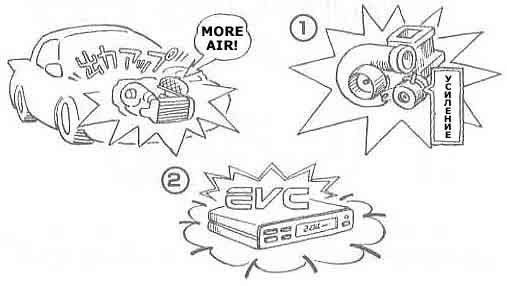

In the process of forced injection of air into the engine, the amount of which is further increased, the explosive force rises, thereby increasing the output power of the motor.

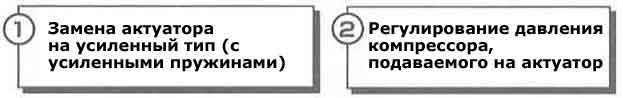

Ways of implementation.

The most common is the second method, carried out with the help of VVC (mechanical pressure pumped pressure controller) or EVC (electric pressure pumped pressure controller). Bust-up is relatively easy to implement, but here, too, there are the previously mentioned problems of knocking the engine (detonation) and limiting the injection. Improper implementation of boost-apa can lead to engine failure, so it is necessary to understand all the nuances of this procedure well before it is implemented.

Concerning the replacement of the turbine.

After the Bust-Up procedure, you can take the next step - replace the turbine.

It is commonly thought that with equally pressurized pressure in these two turbines, the output of horsepower will also be the same. In fact, the power produced by a large turbine will be

INTERKULER IS IT ...

Intercooler is a cooling device or, in another way, a heat exchanger. It "takes" heat from the compressed air passing through it, thereby increasing its density.

Intercooler is a cooling device or, in another way, a heat exchanger. It "takes" heat from the compressed air passing through it, thereby increasing its density.

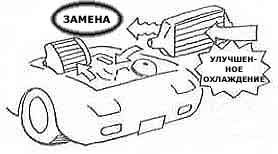

The next step of tuning the engine after boost-apa and replacement of the turbine is to replace the regular intercooler with a larger one, with improved heat transfer characteristics. Obviously, its efficiency is greater than the efficiency of a conventional intercooler. A good intercooler is a device that is capable of combining the performance of two normally conflicting conditions - the minimum pressure loss of the passing airflow as it increases and while cooling it.

INJECTION is ...

Injection is the fuel emitted into the engine for mixing with the air mass that enters it, regulated in accordance with its quantity.

Injection is the fuel emitted into the engine for mixing with the air mass that enters it, regulated in accordance with its quantity.

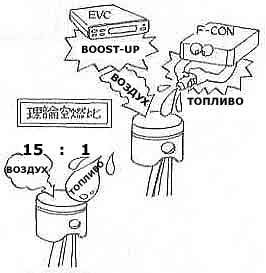

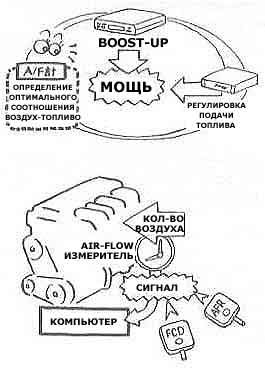

In theory, for the complete combustion of fuel, an optimum air-fuel ratio is required as 15: 1, that is, 15 grams of air need 1 gram of fuel. True, in reality, due to the combination of such factors as the formation of a vapor of the fuel-air mixture and the cooling of the incoming fuel, depending on its brand, the fuel-air mixture formed is actually thicker than optimal. Adjustment of the ratio of the components of the fuel-air mixture is carried out by measuring A / F ( 1 ). In a conventional computer, the adjustment is done using the available oxygen sensors. The computer is responsible for the formation of a fuel-air mixture of a certain quality, creating a proportion of its components, suitable for this standard engine and its normal operating conditions. Receiving the signal from the so - called Air Flow device ( 2 ) (English Air-Flow ), the computer determines the amount of fuel emitted by the injectors ( 3 ), which corresponds to the quality of the fuel-air mixture established by the manufacturer (usually it is thicker theoretically optimal). A normal computer is programmed for normal operating conditions of this engine in the standard version, so when making changes to certain parameters of a particular car, it is also necessary to change the amount of fuel injected.

In practice, the implementation of fuel supply regulation has so far been carried out mainly by devices such as A / F measurement or analyzing devices ( analyzers ( 4 )) that process data from several standard sensors. More progressive in this regard are devices of the type F-con (developed by HKS), which is able to regulate (reduce or increase) fuel supply, receiving signals from the injectors. In addition, depending on the changing signal from  Air-flow, the computer is able to change the ratio of the components of the air-fuel mixture, even when obtaining incorrect data on the amount of incoming air. Thus, F-con includes the functions of AFR and FCD.

Air-flow, the computer is able to change the ratio of the components of the air-fuel mixture, even when obtaining incorrect data on the amount of incoming air. Thus, F-con includes the functions of AFR and FCD.

1) A / F - (English Air / Fuel ) device with a screen that allows you to visually track the ratio of the components of the air-fuel mixture.

2) Air-flow meter ( L- jetro ) - a device that reads the amount of air entering the engine. There may be several types - hot-wire, with a damper and vortex type.

3) Injectors are devices similar to a water tap, which emit a certain amount of fuel, depending on the time period of air supply. This time is transformed into an electrical signal, which is called a signal from the injectors.

4) A device that monitors and stores data streams from different sensors (A / F, engine speed, boost-apa, etc.).

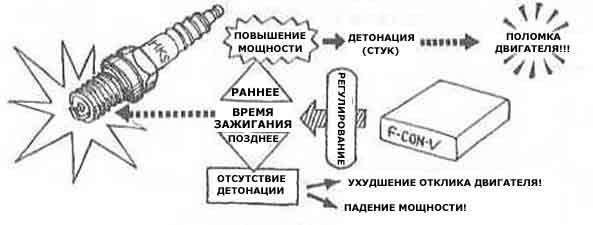

IGNITION SYSTEM

In the ignition system, a significant factor is a strong spark and a reliable ignition. The usual, simplest tuning involves replacing the spark plugs ( 1 ). In addition, the timing also has an ignition value, which, like fuel, is controlled by a computer. The ignition time can vary depending on various conditions, in accordance with the rhythm of ignition of the compressed air-fuel mixture. Generally speaking, if the ignition is carried out with some advance, the output power increases, but at the same time the probability of a knock in the engine (detonation) increases. Conversely, if the ignition is delayed, the probability of a knock is reduced, but at the same time, the output power decreases.

1) Candles always have an indication of the degree of heating in the numerical display (potash number). As a rule, candles with a lower potassium number are of the type of low-heated, and with a large potassium number - respectively, to highly heated. Low-heated candles have a better ability to ignite at their own low temperature, while under the same condition high-heated candles can cause knocking (detonation) in the engine. In turn, at its own high heating temperature, high-heated candles have a better flammability, unlike low-heated candles, which can cause a fire. After the boost-up procedure, the increased explosion force decently raises the temperature in the combustion chamber, which is fraught with the formation of a knock in the engine, and in the worst case, its breakage. Therefore, in this situation, it becomes necessary to use highly heated candles.

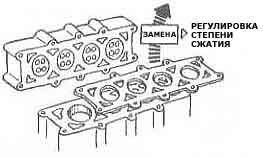

CONTROL OF COMPRESSION

As the air-fuel mixture is compressed in the engine, the explosive force in the cylinders increases, and accordingly, the power output from the engine. At the same time, the likelihood of a knock is also increasing. Therefore, especially in cars equipped with a turbocharged engine, initially set a low compression ratio. This can be done, for example, by replacing the gasket in the engine head.

As the air-fuel mixture is compressed in the engine, the explosive force in the cylinders increases, and accordingly, the power output from the engine. At the same time, the likelihood of a knock is also increasing. Therefore, especially in cars equipped with a turbocharged engine, initially set a low compression ratio. This can be done, for example, by replacing the gasket in the engine head.

STEP 1 (EXAMPLE OF A CAR WITH A TURBINE)

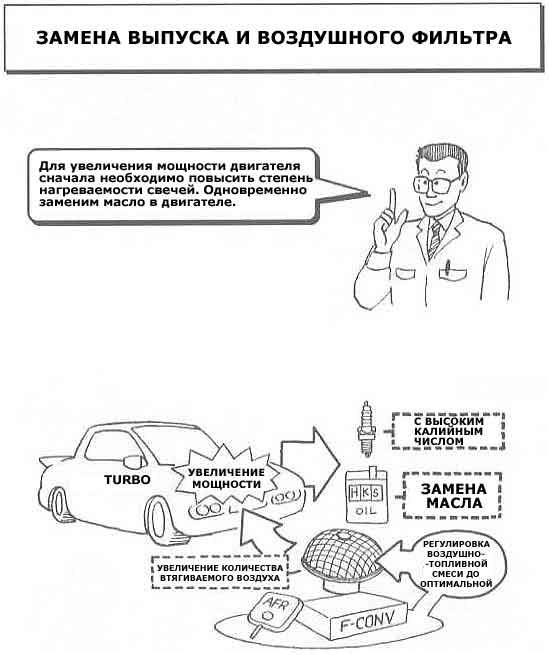

REPLACEMENT AND AIR FILTER REPLACEMENT

Recently, it has become widely accepted that after replacing the air filter the fuel becomes less saturated, as a result of which the engine performance is much improved. In fact, even if you pay attention to the candles, while leaving other details (for example, a computer) ordinary, then the degree of improvement is not that great. After replacing the air filter, the amount of air drawn in will clearly increase, "diluting" the fuel. In this case, tuned to a relatively more "dense" fuel conventional computer, due to the properties of a filter, will provide a certain degree of good quality air-fuel mixture. However, in this case, strictly speaking, there remains an impressive potential for regulating the air-fuel mixture to the optimum state. Having reached it one can achieve one of the main goals of tuning - a clear and instant reaction (response) of the engine to the slightest changes in the actions of the driver. One example of such regulation is the use of devices like AFR or F-con instead of the usual computer.

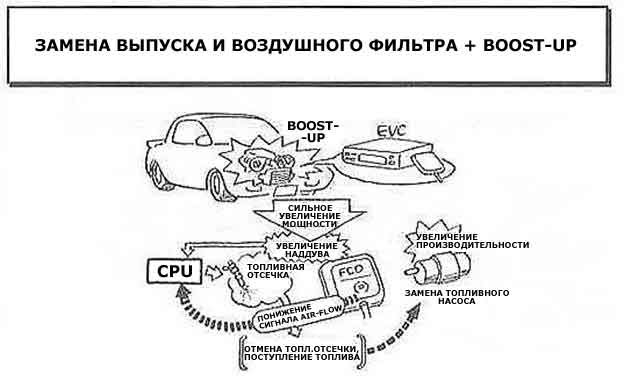

STEP 2 (EXAMPLE CAR WITH TURBINE)

The boost-up is carried out with the help of EVC and VVC. But in order to ensure that when the boost pressure is increased adequately the engine power, it is necessary to adjust the fuel supply regulation. A normal computer in case of exceeding the regular pressure of the air-fuel mixture decides that this is abnormal, and will reduce the fuel supply (fuel cut off) to ensure the safety of the engine. To cancel this procedure, use an FCD type device. With its help, the signal coming with AIR fl ow is reduced, thereby, as it were, removing information from the signal sent to the computer about the increase in the pressure of the air-fuel mixture. Thus, fuel cut-off is prevented. However, since in reality the pressure is increased and the amount of drawn in air increases, it is necessary, respectively, to increase the fuel supply.

In addition, some models of cars are equipped with fuel pumps and injectors that do not have the capacity (reserve) to increase their productivity. Then there is a need to replace such aggregates with more productive ones. The volume (quantity) is determined by special fuel pressure sensors or, so-called IP-monitors (an injection pulse monitor -a monitor showing how many percent of the fuel tap is open). When replacing the intercooler, it is also necessary to regulate the fuel supply in a similar manner.

STEP 3. REPLACING THE TURBINE

In the absence of a visible increase in power (at the sports turbine), it is possible to carry out the boost-apa procedure. However, it should be borne in mind that in this case all engine parts will carry the increased loads, to which the standard components are clearly not calculated. There are sets of turbo-whales ( full turbine kit ), the details of which have increased by an order of magnitude in carrying the applied loads. They are just designed for the corresponding high-power mode.

In the absence of a visible increase in power (at the sports turbine), it is possible to carry out the boost-apa procedure. However, it should be borne in mind that in this case all engine parts will carry the increased loads, to which the standard components are clearly not calculated. There are sets of turbo-whales ( full turbine kit ), the details of which have increased by an order of magnitude in carrying the applied loads. They are just designed for the corresponding high-power mode.

Continuing the above thought, let's say that when the engine power is increased, the remaining elements of the running gear and the braking system leave some dissatisfaction in the course of further operation. In addition, there is a need to strengthen the transmission system. In short, to feel comfortable and confident at the wheel of your "swallow", tuning must be balanced and harmonious.

Continuing the above thought, let's say that when the engine power is increased, the remaining elements of the running gear and the braking system leave some dissatisfaction in the course of further operation. In addition, there is a need to strengthen the transmission system. In short, to feel comfortable and confident at the wheel of your "swallow", tuning must be balanced and harmonious.

In fact, tuning your car is a real pleasure. However, mistaken about the expected result and understanding of the principles of good quality, you can not only cause trouble to others, but also endanger people's lives. Therefore, let us continue to conduct this activity, guided by common sense, and enjoy the results!

In fact, tuning your car is a real pleasure. However, mistaken about the expected result and understanding of the principles of good quality, you can not only cause trouble to others, but also endanger people's lives. Therefore, let us continue to conduct this activity, guided by common sense, and enjoy the results!

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.