What is turbocharger

Undoubtedly, each of us at least once in my life noticed on the usual car with the nameplate "turbo". Manufacturers, as if on purpose, make these small-sized labels and place them in inconspicuous places so that the uninitiated passer-by will not notice and pass by. A person who understands by all means stops and is interested in a car. Below is a story about the reasons for this behavior.

Automotive designers (since the birth of this profession) are constantly concerned about the problem of increasing the power of motors. The laws of physics say that the engine's power directly depends on the amount of fuel burned in one working cycle. The more fuel we burn, the more power. And, say, we wanted to increase the "number of horses" under the hood - how to do it? This is where the problems await us.

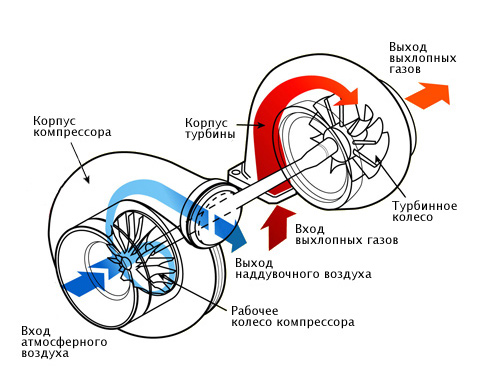

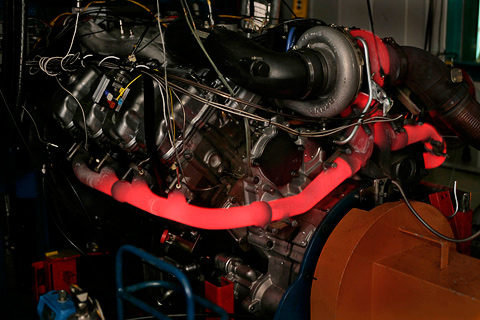

Turbocharger consists of two "snails" - one passes the exhaust gases, and the second "pumps" the air into the cylinders.

The thing is that oxygen is needed to burn the fuel. So in the cylinders, not the fuel burns, but the fuel-air mixture. It is not necessary to interfere with fuel with air, not in the eye, but in a certain ratio. For example, for gasoline engines, 14-15 parts of air depend on one part of the fuel - depending on the operating mode, the composition of the fuel and other factors.

As we see, air is required very much. If we increase the fuel supply (this is not a problem), we will also have to significantly increase the air supply. Conventional engines suck it on their own due to the difference in pressure in the cylinder and in the atmosphere. The dependence turns straight - the larger the volume of the cylinder, the more oxygen it will get on each cycle. So did the Americans, releasing huge engines with a staggering fuel consumption. Is there any way to drive more air into the same volume?

The exhaust gases from the engine rotate the turbine rotor, which in turn drives the compressor, which pumps compressed air into the cylinders. Before this happens, the air passes through the intercooler and cools - so you can increase its density.

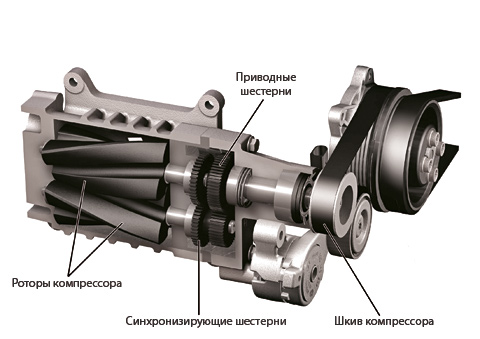

There is, and for the first time invented by his Mister Gottlieb Wilhelm Daimler (Gottlieb Wilhelm Daimler). A familiar name? Still, it is used in the name DaimlerChrysler. So, this German was very good at thinking about motors and in 1885 came up with how to drive more air into them. He guessed to pump air into the cylinders using a supercharger, which was a fan (compressor), which received rotation directly from the engine shaft and forced compressed air into the cylinders.

The Swiss engineer-inventor Alfred J. Büchi went even further. He headed the development of diesel engines in the company Sulzer Brothers, and he categorically did not like that the motors were big and heavy, and the power developed a little. To take away energy from the "engine" to rotate the drive compressor, he also did not want to. Therefore, in 1905, Mr. Büchi patented the world's first injection device, which used exhaust gas as a propulsion device. Simply put, he came up with a turbocharger.

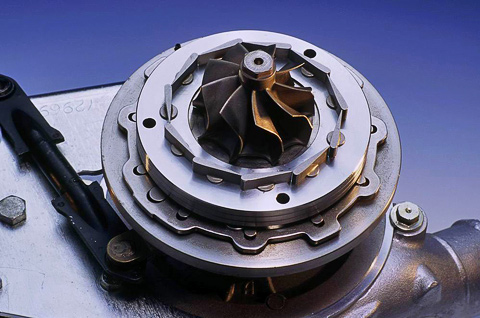

The idea of a smart Swiss is simple, like all ingenious. As the wind rotates the wings of the mill, also the exhaust gases spin the wheel with the blades. The only difference is that the wheel is very small, and there are a lot of blades. A wheel with blades is called a turbine rotor and is planted on one shaft with a compressor wheel. So the turbocharger can be divided into two parts - the rotor and the compressor. The rotor receives rotation from exhaust gases, and the compressor connected to it, working as a "fan", pumps additional air into the cylinders. All this tricky design is called turbocharger (from the Latin words turbo - vortex and compressio - compression) or turbocharger.

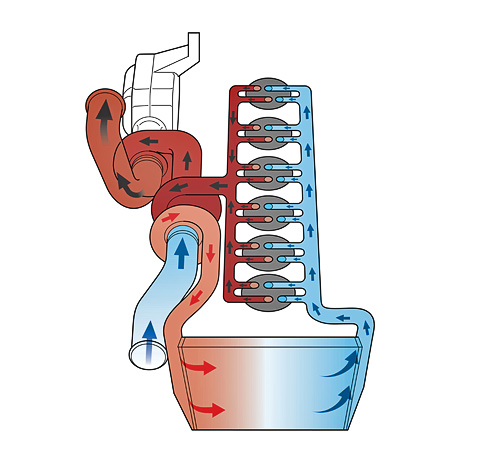

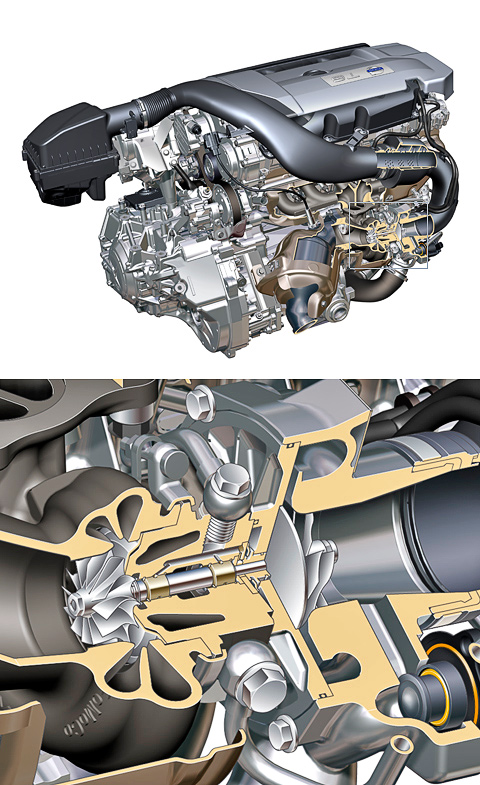

In a turbomotor, the air that enters the cylinders often has to be further cooled - then its pressure can be made higher by driving more oxygen into the cylinder. After all, to compress the cold air (already in the cylinder of the ICE) is easier than hot.

The air passing through the turbine is heated by compression, as well as from turbo parts heated by exhaust gases. The air fed to the engine is cooled with a so-called intercooler (intercooler). This is a radiator installed in the air path from the compressor to the motor cylinders. Passing through it, he gives his warmth to the atmosphere. And the cold air is more dense - it means that it can be driven into the cylinder even more.

The more exhaust gases enter the turbine, the faster it rotates and the more additional air enters the cylinders, the higher the power. The efficiency of this solution compared, for example, with a driving supercharger is that only a little bit of engine energy is spent on "self-service" of the boost - only 1.5%. The fact is that the turbine rotor receives energy from the exhaust gases not at the expense of their deceleration, but due to their cooling - after the turbine the exhaust gases are still fast, but colder. In addition, the free energy expended on air compression increases the efficiency of the engine. And the ability to remove more power from a smaller capacity means less friction loss, less weight of the engine (and the car as a whole). All this makes turbo-charged cars more economical compared to their atmospheric counterparts of equal power. It would seem, here it is, happiness. But no, it's not so simple. The problems have just begun.

First, the speed of rotation of the turbine can reach 200 thousand rpm, secondly, the temperature of the glowing gases reaches, just try to imagine, 1000 ° C! What does all this mean? The fact that making a turbocharger that can withstand such long-term load is very expensive and not easy.

For these reasons, turbo-supercharging became widespread only during the Second World War, and even then only in aviation. In the 1950s, the American company Caterpillar managed to adapt it to its tractors, and the Cummins craftsmen designed the first turbodiesels for their trucks. On serial cars, turbo-motors appeared even later. It happened in 1962, when almost simultaneously saw the light of Oldsmobile Jetfire and Chevrolet Corvair Monza.

But the complexity and high cost of construction are not the only drawbacks. The fact is that the efficiency of the turbine depends heavily on engine speed. At low exhaust speeds a little, the rotor loosened weakly, and the compressor almost does not blow extra air into the cylinders. Therefore, it happens that up to three thousand revolutions per minute the engine does not pull at all, and only afterwards, thousands after four or five, "shoots". This fly-fly is called a turbojam. Moreover, the larger the turbine, the longer it will be untwisted. Therefore, motors with very high specific power and high-pressure turbines, as a rule, suffer from a turbojet in the first place. But in turbines that create low pressure, there are almost no thrust failures, but they do not raise power very much either.

There are also more sophisticated designs. For example, engineers have thought up to install on the motor not one but two turbines. One works at low engine speeds, creating traction on the "bottoms", and the second is turned on later. This decision was called twin-turbo and allowed to kill two birds with one stone - and turbojam, and the problem of power shortage. At the end of the last century, cars with a consistent turbine connection scheme had some popularity, they were produced by Nissan, Toyota, Mazda and even Porsche. However, due to the complexity of the design of the eyelids of such devices, it turned out to be short-lived, and other ideas received dissemination.

For example, a parallel turbo, or biturbo. That is, instead of one turbine, two small identical turbines are put, which operate independently of each other. The idea is this: the smaller the turbine, the faster it unwinds, the more "responsive" the engine turns out. As a rule, two small turbines were put on V-engines, one for each "half".

Another option is a turbine with two "snails", or a twin-scroll. One of them (slightly larger) takes exhaust gases from one half of the engine's cylinders, the second (slightly smaller) from the second half of the cylinders. Both supply gases to one turbine, effectively spinning it both at small and high revs.

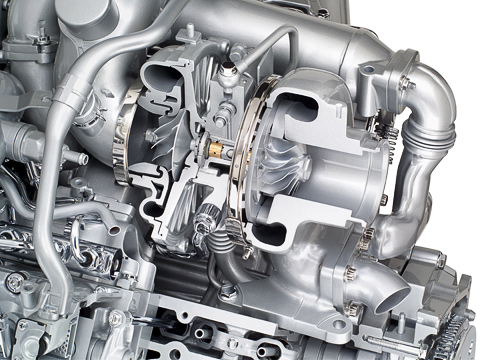

But even on this the designers did not calm down. Naturally, than to fake two turbines, it is much easier to manage one. It is only necessary to make the turbine work equally effectively in the entire range of revolutions. So there were turbines with variable geometry. Here the fun begins. Depending on the speed, special blades rotate and the shape of the nozzle varies. As a result, we get a "super turbine" that works well in the entire range of revolutions. These ideas have been in the air for several decades, but they were realized relatively recently. And first turbines with variable geometry appeared on diesel engines, good, the temperature of the gases there is much less. And from gasoline cars the first tried on such a Porsche turbo 911 Turbo.

The construction of turbomotors was brought to mind a long time ago, and recently their popularity has increased dramatically. Moreover, turbochargers proved to be promising not only in terms of boosting engines, but also in terms of increasing fuel economy and cleanliness of exhaust. This is especially true for diesel engines. Rare diesel today does not carry the prefix "turbo". Well, installing a turbine for gasoline engines allows you to turn a normal-looking car into a real "lighter". The same, with a small, barely noticeable "turbo" label.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.