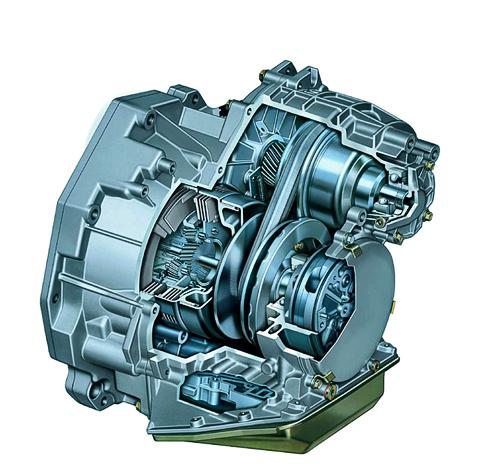

How the variator is arranged. Variator - a special sub-type of automatic transmissions.

Leafing the car collectors, almost all met this phrase: "The car is set continuously variable speed." Either could see this phrase in the table of technical features. What is the mechanical transmission of gear, everyone knows (except, perhaps, the Americans), to the "machine" is also long since all accustomed to (unusually amerikosy). But the Variator (CVT, Multitronic, Autotronic)

Variator - one of the varieties of automatic transmissions. It differs from the lack of fixed stages and ensures a smooth (stepless) change in the gear ratio as far as acceleration or deceleration. According to the design variators visit several types, but the most common (almost the only one on the serial models) is the V-belt variator. In it, the gear ratio changes when the conical pulleys approach and move apart from each other, between which the belt is clamped. These pulleys are moved by a hydraulic drive under the control of electronics, from time to time having several switching modes (for example, ordinary and sporty). Variator little animal little known. But he is far from a novelty.

You will be surprised, but this invention belongs not to Honda and not even to Mercedes. The patent for the variator was issued at the end of the XIX century! Moreover, the first variator was invented and in 1490 at all. His creator was a good bearded Leonardo da Vinci.

The first able-bodied car with this type of box, however, did not originate in the era of the Restoration, but later - in 500 years, in the

In fact, the variator (the more common English designation - CVT - continuously variable transmission) is, sorry for the tautology, a variation on the theme of the automatic box. And the car equipped with it, for the first time, does not give anything away - there are only two pedals and the switch of the modes of the box - P, R, N, D - is the same as for a car with a traditional automatic transmission (automatic box, machine)

The automaton switches gears, providing greater convenience and convenience, also allowing the driver to pay more attention to the road. The automatic transmission protects the engine and the running gear of the car from overloads. Car with automatic transmission, usually, differs by the great expense of fuel and a little bit worse dynamics. But on the final models of automatic transmissions with several switchable control programs (economical, sporty, winter, etc.), and (or) the mode of manual gear selection - this defect is almost eliminated. From an ordinary mechanical box has a couple of main differences: the switching takes place without a break in the power flow between the engine and the wheels. And, almost always (depending on the model), the automatic transmission does not allow the towing of the machine by an ordinary method, but asks for the hanging of the driving axle on the tow truck. In the case of a long tow on the cable, the automatic transmission is out of order. Automatic transmission. Everything is ordinary. But the variator works absolutely differently. In it there are no fixed first, second, tenth gears. Try to imagine how many stars in our universe or how many grains of sand on all the beaches of the Earth taken together - the variator gears are all much much more. And "switching" between them occurs smoothly and insignificantly.

Therefore, here there are no pushes at the touching and "switching". In spite of this, we wrote this word in quotation marks: there are no switchings like these here. Variator constantly and smoothly changes the gear ratio

The gear ratio is the ratio of the number of teeth driven to the number of teeth of the driving gear. Traditionally mentioned in the description of transmissions and various options for their implementation. A larger gear ratio on a particular (first, second, and so on) gear means a great traction. They say that the transfer is "shorter" or "more difficult". The motor quickly untwists to the maximum speed - the car is better accelerated. But with all this, the fastest speed on this gear decreases, and it means there is a need for the most early switching "up". The smallest gear ratio means the "longest" gear. Also from time to time they talk about "close" gear ratios in a box or a "close series". Here, it is assumed that the gear ratios of neighboring steps are close. It is used on cars of a dynamic nature - because when moving to a step up the engine loses less speed, remaining in the zone of the highest torque. "> The gear ratio as the vehicle accelerates or slows down.

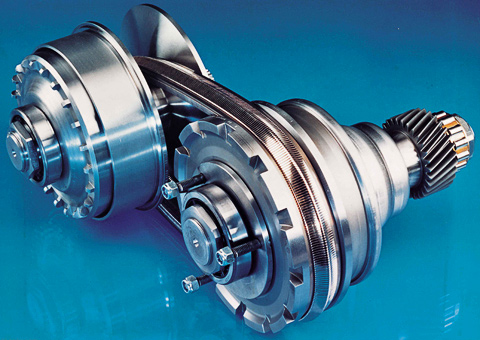

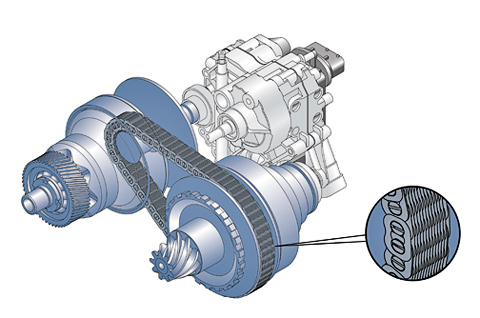

Variators visit several types: V-belts with variable-width pulleys, chain, toroidal ... The 1st type is the most common. Let's see how it works.

Wedge-clutch variator MINI.

Here's a nice example: take two pencils (a cylinder), lying in parallel at a certain distance from each other. We tighten them with an elastic band and begin to twist one of them. Here it starts to turn and the second - with the same speed. But if the pencils are of different diameters, a completely different story begins - until one of them, which is bigger, makes one turn, the second, say, two.

The variator is arranged similar, only the diameter of the "pencils" in it is continuously changing. He has two pulleys, any of which is made in the form of a pair of cones, turned with sharpened ends towards each other. And between the pulleys is clamped a V-belt.

By changing the radius of the belt around the driving and driven pulley, you can smoothly change the gear ratio.

Now, if any of the pairs of cones can move towards each other and back, we will get pulleys with a variable working width. After all, when the cones are moving apart, the belt that touches them with its ribs will seem to fall through the center of the pulley and run around it in a small radius. And when convergence of cones - on a great radius.

It remains only to supply the two pulleys with a system (usually a hydraulics, but maybe

It remains to add a node responsible for changing the direction of rotation of the output shaft (for the reverse), and it may be, say, the ordinary planetary gear

A system of several gears, satellites, revolving around the central, solar, gear. Traditionally, planetary gears are fixed together with the help of a carrier. The planetary gear may also include an additional outer ring gear (crown or epicycle) having an internal engagement with the planetary gears.

Planetary gear can be used as a reducer, when one of the parts is fixed, or for the summation of two power flows. In this version, all the elements are free. "> Planetary gear.

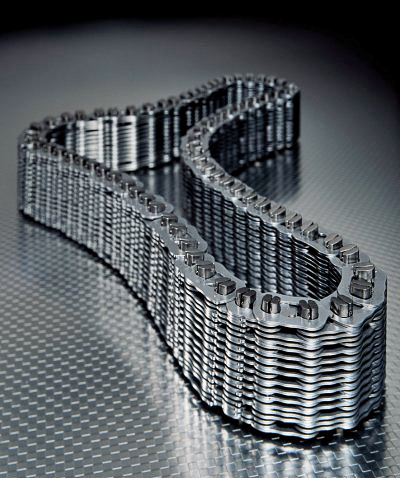

By the way, an entertaining question - what kind of belt is used here? Obviously, an ordinary belt made of rubber and fabric, like those that are turned by generators and other suspension equipment, would not have lived here even thousands of kilometers. Belts in V-belt variators have a difficult device.

Belt in the variator, as you can see, is not a belt at all, but a set of iron ribbons.

з>

з>

This may be an iron tape with some coating or a set of iron cables (tapes) of difficult cross-section on which a huge number of thin transverse iron plates of trapezoidal shape are strung, the edges of which are in contact with the pulleys. By the way, this way it was possible to create a pushing belt that transmits power not only to that half of it, which runs from the slave to the driving pulley, and the opposite one. The ordinary belt when trying to transmit the compressive force would simply have formed, and the metal set-up would acquire rigidity.

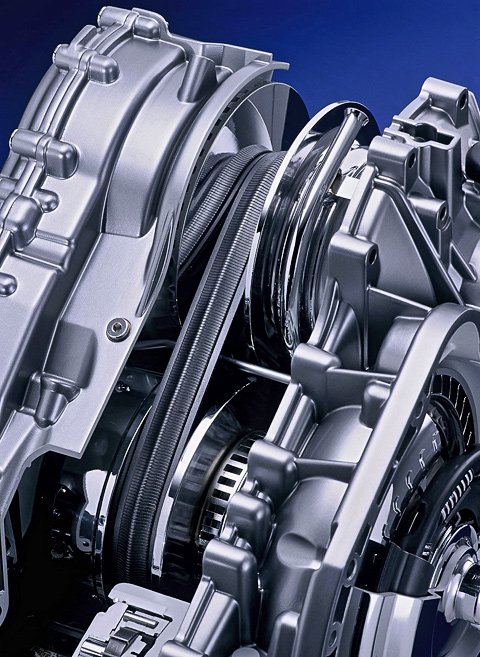

And also as a V-belt can act a wide plate iron chain that touches the cones with its edges. Specifically, the "belt" works in variators of Audi cars.

This is the chain used in the variators of the company Audi ..

з>

з>

Interestingly, a special fluid is used to lubricate the chain, which changes its phase state under the powerful pressure that occurs at the point of contact with the pulley. Due to this, the chain can transmit a forceful effort, not actually slipping, despite the extremely tiny contact area.

How specifically the variator will change the gear ratio during acceleration depends on the selected control program. If during acceleration on an ordinary car we twist the engine on each gear, then we pass to the subsequent transmission, and so on, when the speed of the car with the variator is set, the motor stays on the same revolutions (say, on the revolutions corresponding to the greatest torque), but Smoothly changes the gear ratio.

It creates a few weird feelings. We squeeze gas into the floor, the motor goes to great speed, and so it remains on them during the entire acceleration, howling like a vacuum cleaner. But the pace of acceleration - the highest, well, and the switching between the stages is not wasted.

In general, in some variants, the variator is tuned so that acceleration with it is more prompted by acceleration with an ordinary box, with a gradual increase in engine speed.

Obviously, when you try to drive to the hill and when you slow down the car, regardless of pressing the accelerator pedal, a sensible variator will not leave the "high gear" switched on. Pulleys for assured assault high altitude will move back - to increase the torque at the exit from the box.

And even on some machines you can choose a mode with several "virtual" transmissions (with 6 or even 8), given by the electronics. The transmissions between which the variator will jump abruptly, like a classic automatic box. Even in this version, you can switch "transmissions" at will. As on the "automatic machine" with manual sequential (alternate) mode.

Thus, the variator has a lot of advantages. But there are shortcomings. For example, a relatively small, by modern standards, "digestible" engine power. Not looking at such boxes began their procession around the world on small typewriters. Well, at the moment, strong cars - all pretty often equipped with either "mechanics", or classic "machines", or mechanized boxes.

True, progress is underway. And here it is impossible not to remember the record holders. For example, on the Audi A4 2.0 TFSI the V-belt Multitronic (with a chain) without problems fixes the flow of 200 "horses".

Belt in the variator, as you can see, is not a belt at all, but a set of iron ribbons.

з>

з>

You can argue that class D is not everything. For executive and business class cars, and even more so for a large jeep - 200 forces already can not be called such a great size. But the merits of the most variators that go with the times are not exhausted. So, on the Nissan Murano crossover with a 3,

The second disadvantage of variators is comparable precious service and repair, special, and means, inexpensive, transmission fluid. Belt variators can every

And yet, variators are becoming more and more common on typewriters of various classes, besides, they are, traditionally, cheaper than the excellent "automata" of the classical type.

Since the variators have an unlimited number of gears, they allow the engine to operate in more favorable modes - do we need (at light traffic races) the greatest power, or, against, the smoothness and lower fuel consumption (with serene driving). Therefore, models with variators distinguish, with other identical, the highest profitability, combined with a more solid dynamics.

Belt in the variator, as you can see, is not a belt at all, but a set of iron ribbons.

By the way, in the final period, there has been a trend towards an increase in the number of programs for classical "machines". In the final models, there are already 8 gears (on the car, we will note, the car). And this is done specifically to combine the highest dynamics and economy. Quickly see machines with 10 steps or even with twelve? But the variators are already located where ordinary automata with their switched planetary rows never come. After all, the number of transmissions of the variator is unlimited.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.