GLASSMAT - технология матирования стекла.

Эта новая уникальная технология позволяет качественно осуществлять персонализацию практически любого стекла. Посуда для гостиниц и ресторанов, престижные награды, дизайн витрин и зеркал, номера на стеклах автомашин и т.д. Нет такой стеклянной поверхности, которую нельзя украсить с помощью GlassMat! При этом получаемое изображение на стекле "вечное", его невозможно смыть или соскоблить. Матовая поверхность имеет мелкозернистую, "шелковую" поверхность, на которой не остается жирных отпечатков пальцев.

Основным компонентом технологии является специальная паста GlassMat. Для тех изделий, которые трудно обработать посредством пасты (например, объекты неправильной или круглой формы), применяется жидкость GlassMat. Чтобы формировать защитное покрытие на объектах, обрабатываемых посредством пасты или жидкости, используйте обычный скотч.

РАБОТА С Технология работы с пастой крайне проста и не требует больших вложений средств. Схематично процесс изготовления продукции можно описать следующим образом:

1) Необходимо изготовить шаблон. Для создания шаблона удобней всего воспользоваться режущим плоттером или , в крайнем случае канцелярским ножом.

2) Наклейте на Ваш шаблон лист монтажной пленки, равный по размеру шаблону. Теперь Ваш шаблон представляет из себя трехслойный сэндвич: бумажная подложка, виниловая пленка с клеевым слоем и монтажная пленка сверху.

Перед нанесением шаблона на стеклянный объект, стекло необходимо обработать любым стеклоочестителем и насухо вытереть полотенцем или салфеткой. Разместите шаблон на стекле так, как это требуется. Зафиксируйте его на стекле одним отрезком бумажного скотча вдоль верхнего края.

3) Отогните шаблон от стекла так, чтобы он держался на скотче, как дверь держится на петлях. Снимите бумажную подложку с шаблона, обнажив клеевой слой (не выкидывайте подложку - она Вам еще пригодится. Аккуратно приклейте шаблон используя для этого пластиковую лопатку.

4) Аккуратно снимите монтажную пленку с шаблона. Положив сверху на шаблон бумажную подложку сильно прогладьте его пластиковой лопаткой. Это необходимо, чтобы все части изображения надежно приклеились к стеклу, а между винилом и стеклом не было воздушных пузырей. Бумажная подложка не позволит лопатке зацепить мелкие детали.

5) С помощью монтажного или канцелярского ножа удалите те детали изображения, на месте которых Вы хотите получить матовую поверхность. Не пытайтесь цеплять детали за край - так Вы наверняка повредите ровный край рисунка. Вместо этого сделайте небольшой надрез в центре детали, вставьте в прорезь монтажный нож и медленно и аккуратно отделите деталь от стекла. После того, как Вы отделите от стекла все необходимые детали, накройте шаблон бумажной подложкой и еще раз прогладьте его пластиковой лопаткой.

5) С помощью монтажного или канцелярского ножа удалите те детали изображения, на месте которых Вы хотите получить матовую поверхность. Не пытайтесь цеплять детали за край - так Вы наверняка повредите ровный край рисунка. Вместо этого сделайте небольшой надрез в центре детали, вставьте в прорезь монтажный нож и медленно и аккуратно отделите деталь от стекла. После того, как Вы отделите от стекла все необходимые детали, накройте шаблон бумажной подложкой и еще раз прогладьте его пластиковой лопаткой.

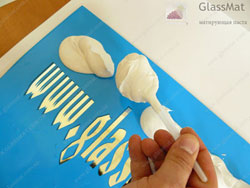

6) Внимательно посмотрите, не осталось ли на матируемых участках стекла частиц клея с виниловой пленки. Аккуратно удалите их ногтем. Не используйте для этого какие-либо стеклоочистители - они могут разрушить весь клеевой слой на виниле. Заклейте полосками винила или бумажным скотчем все области, которые Вы не намерены матировать, но куда случайно может попасть паста. Нанесите толстую полоску пасты GlassMat рядом с вашим изображением.

7) ВНИМАНИЕ! Не выливайте пасту прямо на изображение - в результате оно может получиться неравномерным!!!

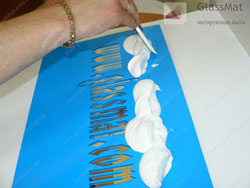

8) Используя пластиковую монтажную лопатку быстрыми движениями нанесите пасту на изображение так, чтобы она покрыла толстым слоем все детали. Никогда не пользуйтесь кисточкой для этого! Оставьте пасту на стекле на 7 минут. По истечении 7 минут при помощи все той же лопатки удалите пасту со стекла или соберите пасту в баночку, если Вы намерены использовать ее повторно. Хорошо промойте поверхность стекла, чтобы на нем и на шаблоне не осталось пасты.

9) Снимите шаблон под струей воды, стараясь делась это так, чтобы струя воды попадала между стеклом и шаблоном. Тщательно промойте и высушите стекло. Теперь ваша картинка останется на стекле навсегда!

ИСПОЛЬЗОВАНИЕ Технология работы с жидкостью также проста и не требует больших вложений средств, как и при работе с пастой.

Схематично процесс изготовления продукции можно описать следующим образом:

- Возьмите пластмассовый контейнер, больший по объему, чем выбранный для обработки объект.

- Разместите выбранный для обработки объект в пустом контейнере. - - Заполните контейнер водой до уровня, необходимого для гравировки.

- Удалите объект из контейнера и отметьте уровень воды на внешней стороне контейнера. Вылейте воду. Высушите сам контейнер и объект.

- Заполните контейнер жидкостью GLASSMAT до отмеченного уровня.

- Медленно опустите объект в контейнер; предотвратите его возможное движение в воде, например, наполнив его водой. Оставьте на 15 минут.

- По истечению указанного времени выньте объект из контейнера.

- Вымойте объект с мылом и водой. Высушите его.

- Перелейте жидкость GLASSMAT в ее первоначальную тару, т.к. жидкость можно использовать многократно.

Изделие готово.

Created/Updated: 25.05.2018