The technology of manufacturing paving slabs.

Author: Yuri Zarva

Source: trotuar.ru

E-mail: [email protected]

|

The process of manufacturing paving slabs includes several basic stages:

PREPARATION FORMSForms for the manufacture of products can be used plastic, rubber and rubber-like (polyurethane). The number of molding cycles that can withstand molds is: for rubber - up to 500 cycles, for plastic - 230-250, for polyurethane - 80-100 cycles. Forms before pouring concrete in them are coated with special compounds or filled with concrete without pre-lubricating the mold. When working without lubrication, the new molds are treated with an antistatic agent, after inspection of the mold, they are inspected and, if necessary, washed with 5-10% hydrochloric acid solution. To lubricate molds, you can use emulsol, OPL-1 (Russia) and SNAA-3 (England). To preserve the surface of the mold, lubricants containing oil products can not be used. The layer of lubricant applied to the surface of the molds must be thin, because the excess of the lubricant leaves pores on the surface of the finished product. Greases emulsol and OPL-1 are applied by brush before each filling, lubricant CPA-3 is applied by brushing or by spraying. Lubricants SVA-3 is sufficient for 2-3 moldings. The temperature during application should be 18-20 ° C. |

FIG. No. 1 |

PREPARATION OF CONCRETE MIXTURESFor the preparation of decorative concrete, it is better to use a forced-mix concrete mixer. Basically the order of preparation of the mixture does not differ from the preparation of ordinary concrete (Figure 1). The pigment is fed about 30 seconds before the cement is fed. |

| Sand + pigment - 15-20 seconds;

Sand + pigment + crushed stone - 15-20 s; Sand + pigment + crushed stone + cement - about 20 s; Sand + pigment + crushed stone + cement + water + additives - 1-1,5 min; Only 2-2.5 minutes. |

To increase the durability of concrete, its wear resistance and impact resistance, it is also possible to add polypropylene, polyamide or glass alkali-resistant fibers 5-20 mm in length and 5-50 microns in diameter in the amount of 0.7-1.0 kg per 1 m3 of concrete. The length of the fibers should correspond to the largest diameter of the coarse aggregate in the concrete. Fibers with good dispersion form a three-dimensional lattice in concrete, which significantly increases the bending strength, impact resistance and wear resistance of concrete.

Polypropylene and alkali-resistant glass fibers are introduced with mixing water; The polyamide fiber is introduced into the finished concrete mixture, i.e. At the last stage, while the mixing time of the mixture is increased by 30-50 seconds.

When using a microsilica additive, the following schedule for the preparation of the concrete mix is adopted:

| Sand + microsilica + pigment - 30-40 s;

Sand + microsilica + pigment + cement - about 30 s; Sand + microsilica + pigment + cement + water + additives - 1-1.5 min. |

FIG. No. 2 - Vibration table |

FORMATION ON A VIBROSTALThe finished concrete mixture has a workability of OK = 3-4 cm. Therefore, short-time vibration processing is used for its compaction. After the preparation of the concrete mixture, it is laid into molds and compacted on a vibrating table (Fig. 2). |

In the production of colored tiles in plastic forms, layer-by-layer molding can be used to save pigment: the first face layer of concrete is prepared using pigment, the second layer of concrete without it. For separate molding it is necessary to have two mixers for the preparation of concrete of the first and second layer. |

FIG. № 3 - There is a curb in the curb. |

When molding, first lay the front layer of colored concrete 2 cm thick and compact for 40 seconds. After this, the second layer of concrete is laid without the pigment and is compacted by vibration for another 20 seconds. With a different mobility of concrete, it is necessary to choose your sealing time on the molding table. |

PRODUCT DEMOLITION

After molding, the products in the molds are installed in stacks 3-8 rows high, depending on the thickness and configuration of the tile. For example, square plates are placed in no more than 3 rows. After this, the piles are covered with a polyethylene film to prevent evaporation of moisture. The holding temperature should be at least 15 ° C. Additional heating is not required. After 24 hours of soaking in molds, it is possible to form (release products from molds).

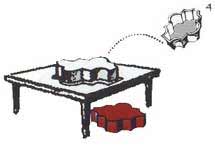

FIG. No. 4 - "Piling" of paving slabs on a vibrating table. |

STRIPPINGFormwork formwork is produced on a special knock-out table with vibration (Fig. 4), while it is recommended to warm 2-3 minutes in a hot water bath (temperature 45-50 ° C) to facilitate mold shavings with products. In this case, the effect of high thermal expansion of polymers is used in comparison with concrete. |

There is a process of knocking out paving slabs.

And its storage on pallets.

FIG. No. 5 - The tiles are packed and ready for sale. |

PACKING AND STORAGEAfter the decking, the tiles are laid on euro pallets "face" to "back", tie them with a packing tape. To ensure the further hardening of concrete and the preservation of the presentation of products, they must be covered with a polyethylene shrink or stretch film. |

In the summer, products are released when they reach 70% of the design strength, which corresponds approximately to 7 days of hardening of concrete, counting from the moment of its manufacture. In winter, leave is made when 100% of the design strength is reached (28 days from the date of preparation of concrete).

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.