Biogas plants

| Biogas plants |

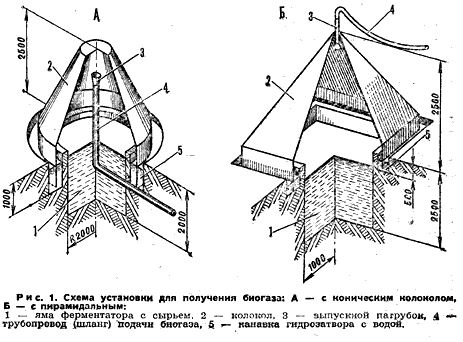

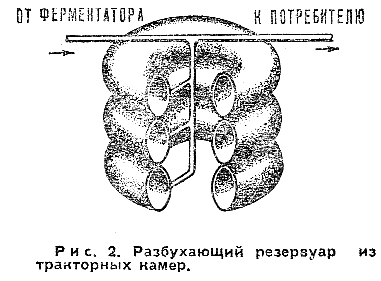

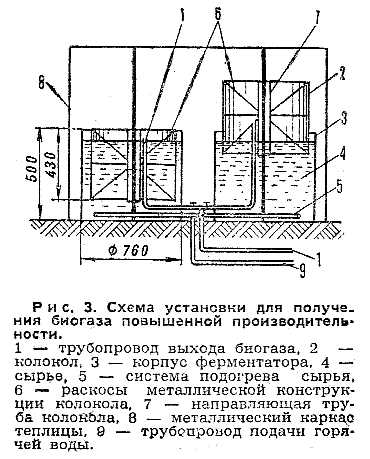

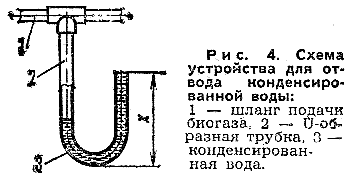

What is biogas?Recently, more and more attention has been attracted to non-traditional, from a technical point of view, energy sources: solar radiation, sea tides and waves and much more. Some of them, such as the wind, were widely used in the past, and today they are experiencing a second birth. One of the "forgotten" types of raw materials is biogas, which was used in ancient China and again "open" in our time.What is biogas? This term refers to a gaseous product obtained as the result of anaerobic, that is, occurring without access to air, fermentation (entrapment) of organic substances of very different origin. In any peasant farming during the year a significant amount of manure, plant leaves, various wastes is collected. Usually, after decomposition, they are used as an organic fertilizer. However, very few people know how much biogas and heat is released during fermentation. But this energy can also serve a good service for rural residents. Biogas is a mixture of gases. Its main components are methane (CH4) - 55-70% and carbon dioxide (CO2) - 28-43%, and also in very small amounts other gases, for example - hydrogen sulfide (H2S). On average, 1 kg of organic matter, biodegradable by 70%, produces 0.18 kg of methane, 0.32 kg of carbon dioxide, 0.2 kg of water and 0.3 kg of an indissoluble residue. Factors affecting the production of biogas.Since the decomposition of organic waste is due to the activity of certain types of bacteria, the environment has a significant impact on it. Thus, the amount of gas produced depends to a large extent on temperature: the warmer, the higher the rate and degree of fermentation of organic raw materials. That is why, probably, the first biogas plants appeared in countries with a warm climate. However, the use of reliable thermal insulation, and sometimes also of heated water, makes it possible to master the construction of biogas generators in regions where the temperature drops to -20? C in winter. There are certain requirements for raw materials: it should be suitable for the development of bacteria, contain biodegradable organic matter and in large quantities water (90-94%). It is desirable that the medium be neutral and without substances that interfere with the action of bacteria: for example, soaps, detergent powders, antibiotics.For the production of biogas, plant and household waste, manure, sewage, etc. can be used. During fermentation, the liquid in the tank tends to be divided into three fractions. Upper - a crust formed of large particles entrained by rising gas bubbles, after a while can become quite solid and will prevent the release of biogas. The liquid accumulates in the middle part of the fermenter, and the lower, mud-like fraction precipitates. Bacteria are most active in the middle zone. Therefore, the contents of the tank must be periodically mixed - at least once a day, and preferably - up to six times. Stirring can be carried out by means of mechanical devices, by hydraulic means (recirculation under the action of the pump), under the pressure of the pneumatic system (partial recycling of biogas) or by various methods of self-agitation. Installations for biogas production.In Romania, biogas generators have become widespread. One of the first individual installations (Fig. 1A) was put into operation in December 1982. Since then, it has successfully supplied gas to three neighboring families, each having a conventional gas cooker with three burners and an oven. The fermentor is located in a pit with a diameter of about 4 m and a depth of 2 m (volume approximately 21 m3), which is laid from the inside by roofing iron, welded twice: first by electric welding, and then, for reliability, gas. For the anticorrosion protection, the inner surface of the tank is covered with resin. On the outside of the upper edge of the fermentor, an annular groove is made of concrete with a depth of approximately 1 m, fulfilling the function of a water seal; In this groove, filled with water, the vertical part of the bell that closes the reservoir slides.The bell is about 2.5 m high - it is made of sheet steel of two millimeters. In the upper part of it, gas is collected.  The author of this project chose the option of collecting gas in contrast to other installations using a pipe located inside the fermenter and having three underground branches - to three farms. In addition, the water in the groove of the hydraulic seal is flowing, which prevents icing in the winter. The fermenter is loaded with approximately 12 m3 of fresh manure, over which cow urine pours out (without adding water, the generator starts working 7 days after filling. A similar arrangement has one more installation (Fig. 1B). Its fermentor is made in a pit with a square cross-section of 2 x 2 and a depth of about 2.5 m. The pit is lined with reinforced concrete slabs 10-12 cm thick, plastered with cement and covered with a resin for sealing. The groove of the hydraulic seal with a depth of about 50 cm is also concrete, the bell is welded from roofing iron and can slide freely on four "ears" along four vertical guides mounted on a concrete tank. The height of the bell is about 3 m, of which 0.5 m is immersed in the groove. At the first filling, 8 m3 of fresh cow manure was loaded into the fermenter, and approximately 400 liters of cow urine were topped up. After 7-8 days, the installation already fully provided the owners with gas. The biogas generator, designed to receive 6 m3 of mixed manure (from cows, sheep and pigs) has a similar construction. This was enough to ensure the normal operation of the gas cooker with three burners and an oven. Another installation differs from any dusty structural detail: near the fermenter are placed three large tractor chambers connected to it by means of a T-hose, connected together (Fig. 2). At night, when biogas is not used and accumulates under the bell, there is a danger that the latter will overturn due to excess pressure. The rubber reservoir serves as an additional reservoir. Fermenter size 2h2x1.5 m is enough for the operation of two burners, and with an increase in the useful volume of the installation to 1 m3, you can get the amount of biogas, sufficient for heating the home. The peculiarity of this variant of the installation is a bell device 138 cm high and 150 cm high from a rubberized cloth used for the manufacture of inflatable boats. The fermenter is a metal reservoir 140x380 cm and has a volume of 4.7 m3. The bell is introduced into the fermenter's manure to a depth of at least 30 cm to provide a hydraulic barrier to the biogas outlet to the atmosphere. In the upper part of the swelling tank, a crane connected to the hose is provided; On it gas is supplied to a gas cooker with three burners and a column for heating water. To ensure optimal conditions for the fermenter to work, manure is mixed with hot water. The best results were obtained with a moisture content of 90% and a temperature of 30-35 °.  To heat the fermenter, the effect of the greenhouse is also used. Above the container is built a metal frame, which is covered with a polyethylene film: under unfavorable weather conditions, it retains heat and makes it possible to significantly accelerate the process of decomposition of raw materials. In Romania, biogas generators are also used in state or cooperative farms. Here's one of them. It has two fermenters with a capacity of 203 m3, closed with a frame with a polyethylene film (Figure 3). In winter, manure is heated by hot water. The plant's capacity is 300-480 m3 of gas per day. This amount is enough to meet all the needs of the local agro-industrial complex. Practical advice.As already noted, the decisive role. The development of the fermentation process is played by temperature: heating of raw materials with 15? Up to 20 ° can double the production of energy. Therefore, often generators have a special system for heating raw materials, but most installations are not equipped with it; They use only the heat released during the very decomposition of organic substances. One of the most important conditions for the normal operation of the fermenter is the availability of reliable THERMAL INSULATION. In addition, it is necessary to minimize heat loss during cleaning and filling of the fermenter bunker.It is also necessary to remember the need to ensure biochemical equilibrium. Sometimes the rate of production of bacteria by acids is higher than the rate of their consumption by bacteria of the second group. In this case, the acidity of the mass increases, and the production of biogas is reduced. The situation can be corrected either by decreasing the daily portion of raw materials, or by increasing its solubility (if possible, with hot water), or, finally, by adding a neutralizing substance-for example, lime milk, washing or drinking soda. The production of biogas can be reduced by the violation of the ratio between carbon and nitrogen. In this case, substances containing nitrogen, urine or a small amount of ammonium salt, used usually as chemical fertilizers (50-100 g per 1 m3 of raw material) are introduced into the fermentor.  It should be remembered that high humidity and the presence of hydrogen sulphide (whose content in biogas can reach 0.5%) stimulate increased corrosion of the metal parts of the plant. Therefore, the state of all the other elements of the fermenter should be regularly monitored and carefully protected at the damage sites: it is best to use lead lead in one or two layers, and then with two more layers of any oil paint. As a pipeline for the transport of biogas from the outlet pipe in the upper part of the bell of the installation to the consumer, both pipes (metal or plastic) and rubber hoses can be used. It is desirable to conduct them in a deep trench to avoid ruptures due to the freezing in winter of condensed water. If the gas is transported by air using a hose, a special device is required to drain the condensate. The simplest circuit of such a device is a U-shaped tube attached to the hose at its lowest point (Figure 4). The length of the free branch of the tube (x) should be greater than the pressure of biogas expressed in millimeters of water column. As condensate drains into the tube from the pipeline, water pours out through its free end without gas leakage.  In the upper part of the bell, it is also advisable to provide a nozzle for installing a pressure gauge in order to judge the amount of biogas accumulated by the amount of pressure. The operating experience of the plants has shown that the use of a mixture of different organic substances as feedstock gives more biogas than when the fermenter is loaded with one of the components. The moisture content of the raw material is recommended to be slightly reduced in winter (up to 88-90%) and increased in summer (92-94%). The water used for dilution should be warm (preferably 35-40 °). Raw materials are served in portions, at least once a day. After the first loading of the fermenter, biogas is often produced first, which contains more than 60% of carbon dioxide and therefore does not burn. This gas is removed to the atmosphere, and after 1 -3 days the installation will start functioning normally. |

Comments

Commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.