One day I made a door for the doorway between the hallway and the living room, with a picture glowing in the dark. At first everything was fine, but the door showed a few flaws.

Firstly, after the tree dried up, it slightly bent (I thought a "sandwich" from a glued tree would prevent it, but alas ... I was wrong ...)

In addition, it had only one layer of organic glass. The problem is that if the glass gets dirty, the dirt also starts to glow. This applies to fingerprints. As luck would have it, both the guests and my households are striving to slam the glass ...

In the end, faced with these problems, I decided to make a new door .

This time I decided to take cheap boards so that the door was straight and stable. In addition, I used four layers of glass - two external 3 mm thick polished glass and two internal 3 mm thick plexiglas, on which the picture is engraved. I had to use plexiglas, because it better conducts light than ordinary glass.

These are four sheets of glass (bringing them home was not easy, but that's another story). By the way, they are green because they are covered with protective plastic.

This is the first piece of cheap wood, cut out in the right shape. In fact, nothing interesting - all you saw, sawing ... Besides, I had to use a milling machine to cut all the boards of 2 mm: I bought boards 22 mm thick, and the thickness of the door - 40 mm. A hell of a lot of fuss. In addition, it was necessary to cut the grooves for the glasses. This process, I did not shoot, unfortunately, but on the other hand, there is nothing interesting in it.

All boards have already been cut to the desired shape. In two boards in the middle, besides, propylenes grooves. As you can see, in the middle layer of cheap boards, larger chips are used. In more detail I will discuss this later ...

This is the lower part of the door. Since the door is quite heavy, I was afraid that the usual wood screws could not stand, so sawed a small groove between two layers of wooden boards and pasted into them three nuts and M5 (A4 stainless steel - for sure). Below is a photograph of the grooves for the two 6 mm nuts and the two threaded rods. They serve as a support for the glass. Glass is fed through the lower part of the door (it would be easier from above, but this is not possible due to the large structural strength of the frame). Under the glass is a board and two threaded rods. Between them, too, is a piece of wood - to strengthen the structure and distribute the weight.

A snapshot of the nuts and washers for the loop close-up. The hinge and screws are already screwed to ensure that the nuts are stuck in the right place.

All is glued and filled with filler.

Slotted grooves for glass close-up. I had to use a filler to flatten the surface, because in the middle the density of the boards is less. In addition, I carefully sawed the edge with a milling machine. I hoped that the paint would be enough to fill all the irregularities and make the tree smooth ... alas, it did not work out. Here, too, had to use filler (photos, again, no ...).

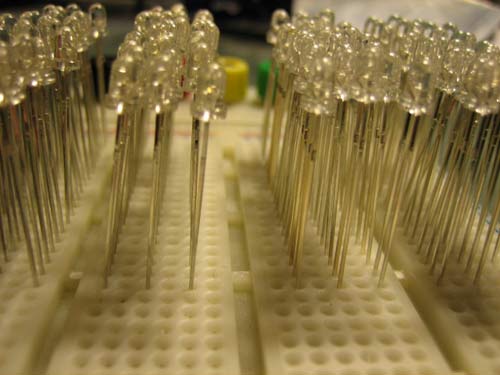

LEDs! To be precise - 120 pieces, 60 blue and 60 white. They will illuminate the glass.

Holders for LEDs made of strips of Plexiglas 3 mm thick, 1 x 62 cm. I cut through the hole for each LED and for each resistor (one resistor for three LEDs). In addition, I had to cut a groove for the cord. It will be located above and under the glass, under the weight of one sheet of Plexiglas.

It's on!

A picture of strips with light-emitting diodes close-up looks like an art photo. White seems bluish - forgot to adjust the white balance on the camera ...

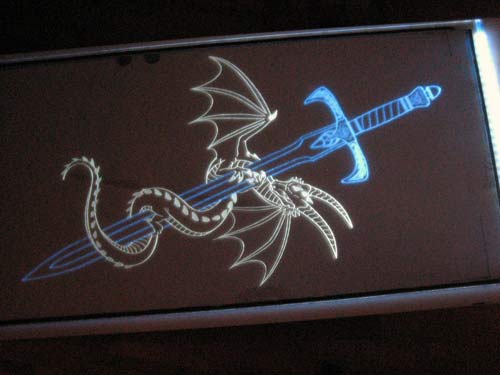

This is the first layer of glass with an engraved pattern on it (it will be blue).

... And the second layer (it will be white).

Both layers are connected to each other. Engraving is located on both sheets from different sides. Ideally, it would be nice to engrave the drawing on both sheets on the same side, but in that case the image would look fine at right angles, but would double if viewed at an angle (the patterns would not coincide with each other by 3 mm).

Therefore, the sides on which the picture is carved are arranged face to face. The problem is that at the same time the picture seems somewhat clearer on one side than on the other. However, as a result, everything was not as scary as I expected.

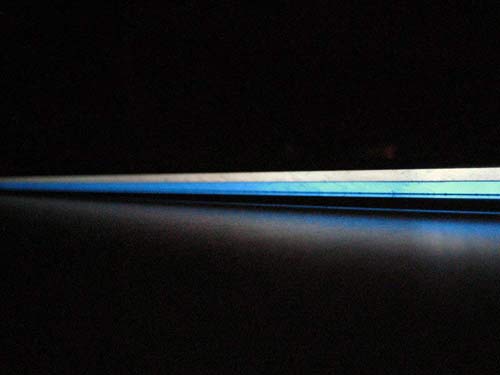

This is a very bad photograph of the first sample of LEDs. All four sheets of glass are stacked on top of each other. The black edge visible in the picture is the tape that serves as a gasket / sealant.

By the way, the whole construction lies on the other door - not the one I replace.

Here we see how the light is distributed over the glass. The outer glass does not let light in at all, and the plexiglass lets in two different colors. The light is dissipated much less than I expected. In fact, the blue color is much "cleaner", just my camera could not fix the pure blue glow of the LEDs.

This is a ready "sandwich". The white film ensures that the glass will hold tightly in the wooden frame of the door.

Unfortunately, I was not able to completely clean the glass. If you look at an angle, it is noticeable dirt. But this, fortunately, is not deadly.

It turned out that the "sandwich" was even too dense - I had to push hard on the glass to cram it into the frame (and lime so much grease that any nightclub would envy). As a result, I managed to push the glass into the frame, but I will be able to pull it out - time will tell. I hope, I still will never have to take it out.

A picture of a close-up picture.

Note: the blue and white colors overlap slightly. In the photo, blue seems very heterogeneous, but in fact, it looks much better. So it happened because the white is shown here from the "right" side, and the blue one from the "inside".

And here, at last, the door is entirely in the illuminated room. The light in the hallway is off. The glass is absolutely transparent, but in the photos taken with the light on, the picture looks bad. True, in reality this problem does not exist.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.