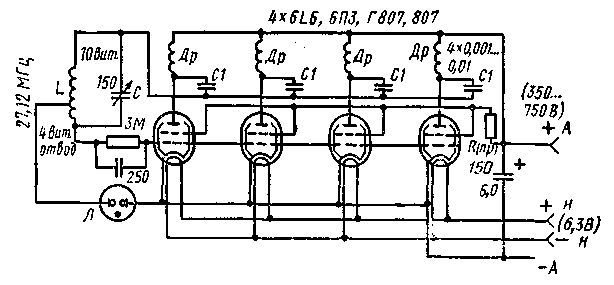

Scheme of a self-made induction furnace

| Scheme of a self-made induction furnace |

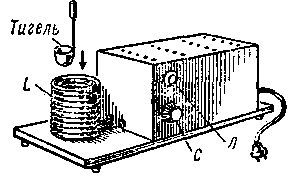

Homemade melting induction furnaceThe current induction furnace model is shown in Fig. The HF generator generates oscillations with a frequency of 27.12 MHz. It is assembled on four electron tubes (tetrodes). Neon lamp signals the device is ready for operation. The variable capacity capacitor (CPE) handle C is output to the outside. With the maximum capacity of the KPE, a quick heating of a piece of metal placed (in a crucible) in a coil L takes place.  Fig.1. The circuit of the generator. To melt a piece of zinc, it is enough to heat it for 15 ... 20 seconds. The coil L is frameless, consists of 10 turns of PEV wire 0.8, the inner diameter of the turn is 12 mm. Condenser C from the broadcast radio (with each second plate removed).  Fig.2. The power of the device is such that it almost instantly heats up to red heat, for example, a screwdriver. The rate of metal melting in induction furnaces depends primarily on the generator power, frequency, hysteresis losses, eddy currents in a piece of metal and the rate of heat transfer to the environment. Lamps are recommended to use powerful, but the number of them with parallel inclusion should not exceed four. The oven is powered by an AC 220 V via a rectifier. Capacitors C1 - ceramic or mica with an operating voltage of 1500 ... 2000 V, Dr-chokes of high frequency. |

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.