Production of an air corn machine

| Production of an air corn machine |

|

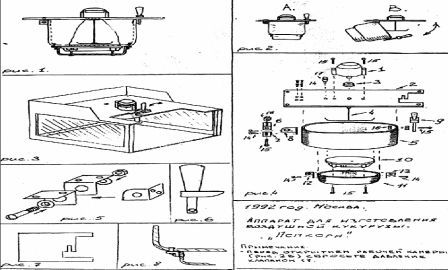

This unit is designed for production at home and is designed for the production of air corn in separate portions. The main nodes are: 1. The working unit (Figure 2) is intended for the direct preparation of air corn and consists of the following elements: slow-moving e. The engine -1, the plate is 2 (aluminum), the gland is 3, the blades are 4 (aluminum), the working capacity is 5, the turning unit is 6.7, 8 (aluminum), the locking unit is 9 (aluminum), steel, handle From wood), heating element - 10 (marmite from El. Tiles); Heating element casing - 11; Angles of fastening of a casing - 12, 13, rivets - 14; Bolts - 15; Nuts - 16; The plate 2 is made with a cutout of a special shape (Figure 7) to ensure fixation of the locking unit 9. The handle of the locking unit is manufactured as shown in Fig. 6 (it must ensure a tight fit of the working container 5 to the plate 2). The swivel unit is manufactured as shown in Fig. 5. The casing of the heating element 11 is fixed to the working container 5 (see Figure 8) 2. Container. It is intended for installation of the working unit and short-term presale storage of air corn. Performed in an arbitrary shape of metal or wood (Figure 3) 3. Electrical equipment. Includes El. The motor for driving the blades and the heating element. A power regulator, fuses, and a switch can be connected. 4. Controls. Are intended for inclusion Эл. The engine and the heating element. Cooking of popcorn: 1. Open the working unit (Fig. 2c), fill the corn grain, pre-mix it with sunflower oil and salt 2. Set the device in the working position (Fig. 2a), turn on the El. Engine and heating element. After a certain time (after the moisture is transferred to the steam and excess pressure is generated in the working vessel), insert El. Engine and open the working chamber (Fig. 2c). The pressure of the container will be compared with the atmospheric pressure and the grain will break. The air corn is ready. Unload it with a scoop (spoons) from the container and fill a new portion of the grain. Notes: 1. Operating time, rotation speed El. The engine, the heating temperature, the proportional ratio of oil, salt and grain is determined experimentally, based on the quality of the product obtained. 2. The rupture of grains can occur only from heating, i.e. Without differential pressure (if you did not manage to achieve tightness of all connections). But in this case, the quality of air corn will be lower. 3. The dimensions of the parts are not given intentionally, because they depend on the finished elements (engine, capacity) that you have. 4. It must be taken into account that this documentation is not a dogma, but a guide to action and the specific manufacture of the device depends on your capabilities. 5. When assembling and operating the device, it is necessary to remember: the device operates under pressure, at high temperature and high voltage. This can be life threatening. Be sure to install the safety valve 17 from the pressure cooker

|

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.