Ультразвуковой металлоискатель

Ультразвуковой металлоискатель

А. Гошев, г. Ростов-на-Дону

В практике любителей поиска кладов большинство случаев обнаружения металла оказываются "пустыми", то есть найденный предмет - это простая ржавая железка, а времени на работы по ее извлечению бывает затрачено много. Для того, чтобы освободить искателей от лишней работы и дать им возможность сразу при обнаружении металла определить его наименование, и разработана эта схема.

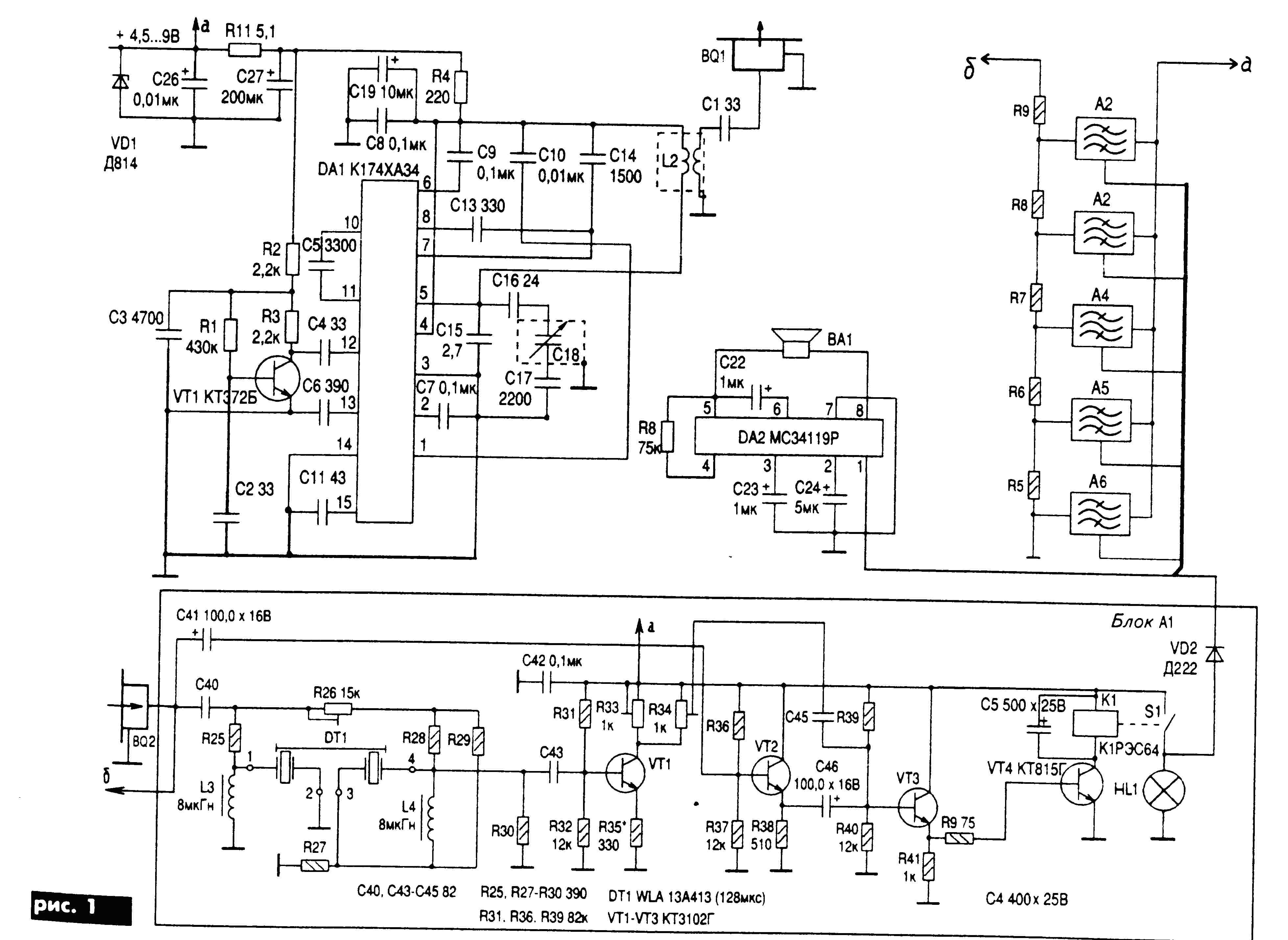

Схема ультразвукового металлоискателя показана на рис. 1. В основе принципа действия его заложено свойство магнитострикции, которое проявляется как изменение размеров металлического предмета при действии на него механической силы в постоянном магнитном поле.

Излучатель - пьезоэлемент BQ1 воздействует на грунт или строительные конструкции, которые чаще всего скрывают искомый предмет, ультразвуком с частотой 6 МГц. Длина волны излучения таково, что частицы кристаллической решетки веществ полупроводникового типа, например, кремний, кальция, и пр. или молекулы таких веществ, как углерод, хлор и др., из которых состоит почва или стены домов, приходят в неравновесное состояние. Оно характеризуется с одной стороны передачей механического воздействия ультразвука от частицы к частице, а с другой стороны - появлению так называемого состояния "текучести" веществ в ультразвуковом поле. Вследствие этого металлические предметы оказываются как бы взвешенными или свободно плавающими в области "текучести".

Вещество в состоянии "текучести" переизлучает сверхширокий спектр ультразвуковых колебаний (рис. 2) со средней частотой 6 МГц, при этом ширина полосы достигает 5 МГц. В нижней части полосы и находятся частоты магнитострикционных резонансов наиболее часто отыскиваемых металлов, которые обозначены спектральными составляющими (рис. 2). Металлические предметы возбуждаются на частотах собственных резонансов, отличных от других, при этом амплитуда резонансного излучения превышает шумовой фон области "текучести", что и позволяет осуществить их обнаружение.

Конструкция металлоискателя (рис. 1) состоит из передатчика, собранного по отечественной микросхеме типа К174ХАЗА по емкостной трехточке с параметрической стабилизацией частоты на транзисторе VT1, многоканального приемника в виде линейки частотно-селективных преобразователей-индикаторов Al…A6 и сигнализатора обнаружения на микросхеме типа МС34119Р (DA2). Передатчик, запитанный от одной-двух плоских батареек, нагружен на пьезоэлектрический излучатель BQ1, который для увеличения рабочей частоты укреплен на платформе из электротехнической стали весом

Такой же пьезоэлемент BQ2 используется для приема ультразвуковых колебаний, поэтому его помещают на аналогичную платформу по соседству с передающей, а для развязки по частоте излучения их граничащие ребра прокладывают резиной. С пьезоэлемента входной сигнал поступает на приемные модули каналов A1…A6, отличающиеся только по частоте настройки входных электромеханических фильтров, которая для алюминия (A1) равна 3245 кГц, для меди (А2) 3872 кГц, для железа (A3) 4731 кГц, для серебра (А4) 5278 кГц, для золота (А5) 5621 кГц и для платины (A6) 5722 кГц.

При наличии сигнала на входе усилителя канала, превышающего уровень шума, сигнал детектируется, усиливается и заставляет сработать реле К1, включающее световую сигнализацию, свидетельствующую о наличии металла определенного наименования. Одновременно в цепи индикатора путем подачи напряжения питания на генератор ЗЧ DA2 через развязывающий диод VD2 включается звуковая сигнализация.

Схема метоллоискателя проста, однако колебательная система передатчика и фильтры приемника требуют тщательной настройки по методикам, широко известным радиолюбителям.

Детали и элементы конструкции намеренно взяты доступными, чтобы облегчить повторение конструкции.

РАДИОАМАТОР 4’2001

Created/Updated: 25.05.2018