Simple ultrasonic washing machine

| Simple ultrasonic washing machine |

|

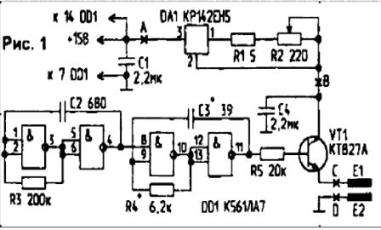

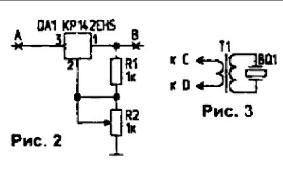

The introduction of advanced energy-saving technologies put forward a new device for household use, an ultrasonic washing device, to the forefront of progress. Washing by ultrasound occurs due to the periodic formation in the volume of the liquid compression-rarefaction waves arising in a practically incompressible medium - water. Linen placed in such a liquid is subjected to intense hydroacoustic effects. Hydroacoustic waves initiate the appearance of microscopic gas bubbles that contribute to the separation of microparticles of dirt from the volume of the laundry being washed. In the formation and subsequent collapse (destruction) of gas bubbles, ozone is formed, sterilizing laundry. In a number of cases, with a large energy of ultrasonic vibrations, sonoluminescence can be observed-liquid glow, especially noticeable in a darkened room. The advantage of washing using ultrasonic vibrations is that the laundry is not deformed, does not rub and does not break. It is possible to wash even woolen clothes and thin linen. In addition to washing and disinfecting the laundry, it is possible to process vegetables and fruits intended for preservation, to disinfect water. The ultrasonic washing devices (UOS) of the "Bionika" type appeared on the market [1] represent a compact electric device weighing 200 g. "Bionics" consists of a network adapter - a power source and the ultrasonic ultrasound. The device itself is filled with a compound in order to preserve the know-how, and a description of its conceptual scheme and meaningful for reproduction of the characteristics is not given. However, having secondary characteristics obtained by measuring and analyzing the modes of the device, it is possible to imagine one of the possible schemes of a SSS in the following form (Fig. 1).  The SSS consists of a power source (DA1 chip), two interconnected generators operating at 10 kHz and 1 MHz (DD1 chip), an output stage on a VT1 transistor and an emitter activator connected to the C and D points of the device. The power source in the prototype is made unregulated, designed for the maximum power consumed from the network - 3 W, which is enough to wash the laundry in a liquid volume of 10 ... 25 liters. It would be more expedient to provide the UZS with a smooth adjustment of the output power. In Fig. 1, a controlled source of stabilized direct current (25 ... 1000 mA) is included in the gap between points A and B.  Figure 2 shows a diagram of the regulated power supply (5 ... 13 V). The pulse packet generator is made according to the traditional scheme on the DD1 chip and has no features. The RC elements of the high-frequency part of the generator can be corrected by tuning the frequency into resonance with the frequency of the ultrasonic radiator-activator. The DA1 chip and the VT1 transistor should be installed on the heat sink plates. The most problematic in the practical implementation of the ultrasonic vibrating system is the selection of an ultrasonic radiator-activator and provision of its waterproofing while achieving the maximum energy return of ultrasonic vibrations to the environment (liquid). Usually, piezoelectric ceramics - barium titanate, strontium, radiators on ferrite or permalloy cores, piezoquartz plates (Fig. 3) [2-4] are used as an ultrasonic radiator, which opens a wide field for the experiment. One interesting option for obtaining ultrasonic vibrations is simply to transmit pulses of electric current through water using a system of closely located electrodes connected to points A and B of the device. Periodic passage of current pulses between the electrodes will cause acoustic electrostimulated modulation of the solution. Electrodes can be recommended aluminum or graphite. When washing, a reliable isolation from the mains supply must be ensured. The washing container (bucket, pelvis) should be removed from grounded items and installed on a dry floor. Acoustic vibrations in the washing solution can also be excited in the range of sound frequencies. Experiments have shown that washing under such conditions occurs with an acceptable result in comparison with the prototype. Features of washing with the use of ultrasound - in the washing solution, as much washing powder as for hand washing, the temperature of the water should be about 65 ° C. The underwear should float freely in a solution, occasionally it should be stirred with wooden forceps. Strongly soiled areas of laundry are recommended to be additionally lathered. The washing process lasts 30 ... 40 minutes or more (depending on the efficiency of the ultrasound activator). Rinse the laundry can also be using ultrasound. It should be noted that the experience of the optimal use of ultrasound displays after several washings. |

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.