The first designs of DC motors. Part 3

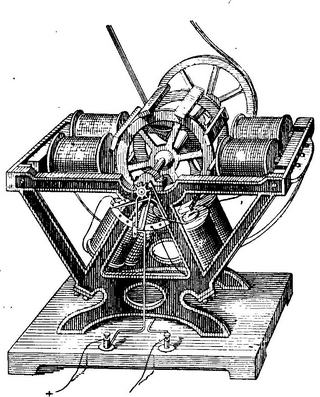

Devenport Electric Motor

In 1837, an American technician, T. Davenport, also built an electric motor with a direct armature rotation in which mobile electromagnets interacted with fixed permanent magnets. In this design, there were some progressive ideas, to which, apparently, the designers of electric motors, including BS Yakobi, drew attention.

The Davenport electric motor had four horizontal cruciform electromagnets mounted on a wooden disk rigidly connected to a vertical shaft. These electromagnets were located inside two permanent magnets in the form of semicircles, supported by a wooden ring; Magnets touched the same poles and created a ring with two poles: N and S.

On a special stand were placed copper plates, separated in the middle of the insulation. They were supplied with current from the power source. The ends of the series winding of each pair of electromagnets had spring contacts. The interaction of electromagnets and permanent magnets drove the electric motor into operation, with the polarity of the electromagnets changed at appropriate times with the help of the switch's power.

The new Jacobi engine of 1838

The Jacobi engine of the 1838 design was a combination of 40 small electric motors, combined in 20 pieces. On two vertical shafts installed in a wooden frame. The stationary part of each electric motor consisted of two electromagnets curved along an arc of a circle and fastened together by clips of non-magnetic material; These braces were screwed to a wooden frame. Each of these electromagnets occupied a quarter of the circumference of the ring along the length.

The moving part of the individual electric motors was composed of four electromagnets, located crosswise on a special bushing. To supply current to the windings of electromagnets on an "electric boat", galvanic cells were installed.

The change in the direction of the current in the windings of movable electromagnets was carried out by switches similar to the commutator of the first electric motor described above. By means of bevel gears, the rotation from the vertical shafts was transmitted to the horizontal shaft, on which the propellers mounted on both sides of the "electric boat" were reinforced.

Familiarity with this design of the electric motor shows that B. S. Jacobi went that way of mechanically connecting a certain number of elementary machines. This Jacobi's work reflected a typical tendency for the development of electric machines in the middle of the last century, when scientists, not finding yet qualitatively new solutions, tried to satisfy the needs of practice by simply combining a large number of existing machines.

Technical and economic characteristics of the first electric motors

Tests of Jacobi electric motors installed on the boat found that when the electric motors are powered by current from galvanic batteries, the mechanical energy is obtained excessively expensive; Because of this, the extreme inefficiency of electric motors was recognized - at this stage in the development of electrical engineering.

It should be noted that the main drawback of galvanic batteries is their low energy capacity (ie, low power per unit weight), which forced to use a very large number of batteries, which is unacceptable for many transport installations. So, for example, on the Jacobi bot, 320 galvanic cells were first installed.

Practical application of the first engines

The experiments carried out, as well as the theoretical study of the electric machine, led Jacobi to a very important conclusion for practice: the resolution of the question of the more or less wide application of electric motors is directly dependent on the cheapening of electric power, ie, from the creation of a current generator more economical than galvanic batteries .

However, even under conditions where the electric motors could only be powered by galvanic cells, in practice there were cases when it was more advantageous to install an electric motor than an aggregate for obtaining mechanical energy from a steam engine. Therefore, in the 50's and 60's in some industries, the motor was sometimes used.

As one example, you can specify a printing house. At that time, most of the production operations in printing houses were carried out either manually or manually. The appearance of large presses required the drive from the engine. For one large printing press, usual for a printing house of that time, which worked periodically, and not for the whole working day, it was easier to use an electric motor.

In these and similar cases of practice abroad, the electric motor of the French electrical engineer PG Froman had some distribution.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.