How are the power transmission towers arranged?

E-transmission line (LEP) is one of the components of the electric network, a system of power equipment designed to transmit electricity through an electric current. Also an electric line in the structure of such a system, which goes beyond the limits of a power station or substation. There are air and cable power lines. Recently, the gas-insulated lines GIL have become popular. The transmission line also transmits information using high-frequency signals (according to experts, about 60,000 HF channels over the transmission lines are used in the CIS) and FOCL. They are used for dispatching control, telemetry data transmission, relay protection signals and emergency automatics. It is also noteworthy that in the 1985s, developments were made for power lines reaching a height of 70 meters.

Support of the overhead power line (power line support) is a structure for holding wires and, if available, lightning protection cables of the overhead power transmission line and fiber-optic communication lines at a given distance from the ground surface and from each other.

What can be more ordinary than power lines? Power line supports are one of the most common engineering structures, and they are always in front of our eyes. However, in this sphere too, there are technological subtleties and even scope for technical progress. Not very noticeable for us overhead power lines acquire a new look and a new design.

Most often, we imagine the support of transmission lines in the form of a lattice construction. About 30 years ago this was the only option, and these days they continue to build. A set of metal corners is brought to the construction site and a support is made step-by-step from these standard elements. Then comes the crane and puts the structure upright. This process takes quite a long time, which affects the timing of the laying of lines, and these supports with dull lattice silhouettes are very short-lived. The reason is a weak protection against corrosion. The technological imperfection of such a support is supplemented by a simple concrete foundation. If it is done in bad faith, for example with the use of a solution of inadequate quality, then after a while the concrete becomes cracked, water gets into cracks. Several cycles of frost-thawing, and the foundation must be remade or seriously repaired.

Pipes instead of corners

The fact that the alternatives are replacing the traditional supports made of ferrous metal, we asked the representatives of PAO Rosseti. "In our company, which is the largest electric grid operator in Russia," says the expert of this organization, "we have long been trying to find a solution to the problems associated with lattice supports, and in the late 1990s began to move to the pivot. These are cylindrical racks of bent profile, in fact pipes, in cross-section having the form of a polyhedron. In addition, we began to apply new methods of corrosion protection, mainly the method of hot-dip galvanizing. This is an electrochemical method of applying a protective coating to the metal. In an aggressive environment, the zinc layer is thinned, but the supporting part of the support remains unscathed. "

Supports of electric overhead lines, we usually imagine this way. However, the classic lattice design gradually gives way to more advanced options - multi-faceted supports and supports made of composite materials.

In addition to greater durability, the new supports are also more simple to install. There is no need to make any more corners: the tubular elements of the future support are simply inserted into each other, then the connection is fixed. Mount this design can be eight to ten times faster than the collection of trellised. Corresponding transformations have undergone also the foundations. Instead of the usual concrete steel, the so-called piles are used. The design is lowered to the ground, the return flange is attached to it, and the support itself is already placed on it. The estimated service life of such supports is up to 70 years, that is, about twice as much as in latticework.

Why the wires are buzzing

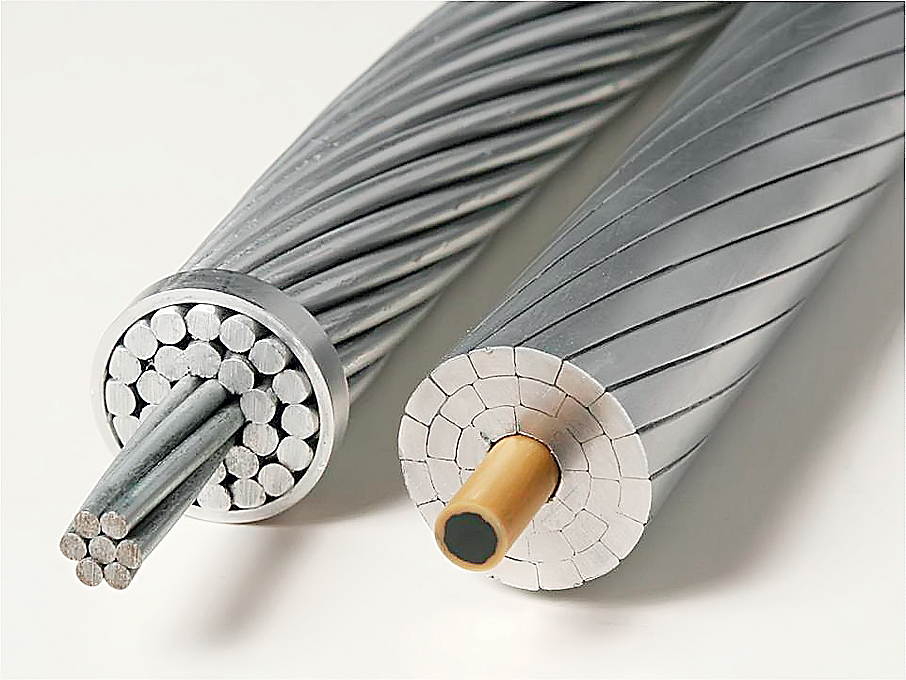

And the wires? They hang high above the ground and from a distance look like thick monolithic cables. In fact, the high-voltage wires of the suite from the wire. The usual and widely used wire has a steel core that provides structural strength and is surrounded by an aluminum wire, the so-called external coils, through which the current is transferred. Between the steel and aluminum, a lubricant is laid. It is needed in order to reduce the friction between steel and aluminum - materials that have a different coefficient of thermal expansion. But since the aluminum wire has a circular cross-section, the turns do not adhere to each other loosely, the wire surface has a pronounced relief. This shortcoming has two consequences. First, in the gap between the coils penetrates moisture and flushes out the lubricant. Friction increases, and conditions for corrosion are created. As a result, the life of such a wire is no more than 12 years. To extend the service life, the wire is sometimes worn repair cuffs, which can also cause problems (more on this later). In addition, this design of the wire contributes to the creation of a distinct hum around the air line. It occurs because the alternating voltage of 50 Hz gives rise to an alternating magnetic field that causes the individual veins in the wire to vibrate, which results in their collision with each other, and we hear a characteristic buzz. In the EU countries, such noise is considered an acoustic pollution, and it is being fought with. Now such a struggle has begun with us.

"We now want to replace the old wires with wires of a new design, which we are developing," says the representative of PJSC "Rosseti". - This is also steel-aluminum wires, but the wire there is not applied round-shaped, but rather trapezoidal. The povil turns dense, and the wire surface is smooth, without cracks. Moisture can hardly get inside, the lubricant is not washed away, the core does not rust, and the life of such a wire is approaching thirty years. Wires of similar design are already used in countries such as Finland and Austria. Lines with new wires are also in Russia - in the Kaluga region. This is the line "Orbita-Sputnik" with a length of 37 km. And there the wires have not only a smooth surface, but also another core. It is not made of steel, but of fiberglass. Such a wire is lighter, but stronger to break than conventional steel-aluminum. "

However, the latest design achievement in this area can be considered a wire created by the American concern 3M. In these wires, the carrying capacity is provided only by current-carrying coils. There is no core, but the coils themselves are reinforced with aluminum oxide, which ensures high strength. This wire has excellent load-carrying capacity, and with standard supports it can withstand its spans of up to 700 m (standard 250x300 m) due to its strength and low weight. In addition, the wire is very resistant to thermal loads, which causes its use in the southern US states and, for example, in Italy. However, the wire from 3M has one significant disadvantage - too high a price.

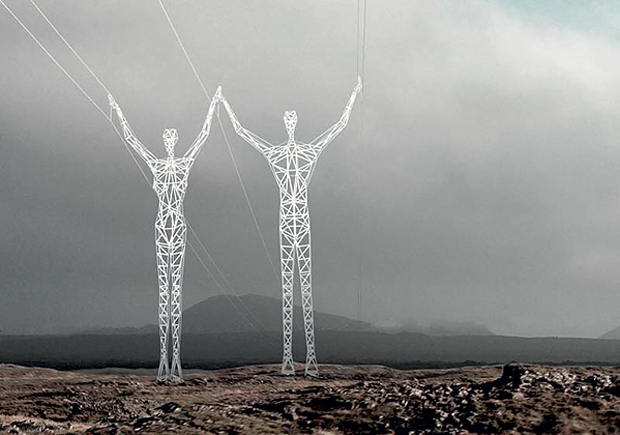

The original "designer" supports serve as an undoubted adornment of the landscape, but they are unlikely to become widespread. In priority, electric grid companies have the reliability of energy transfer, and not expensive "sculptures".

Ice and Strings

The overhead power lines have their own natural enemies. One of them is icing wires. Especially this disaster is typical for the southern regions of Russia. At a temperature near zero drops of drizzle fall on the wire and freeze on it. A crystalline cap is formed on the top of the wire. But this is only the beginning. The cap under its own weight gradually turns the wire, substituting the other side for the freezing moisture. Sooner or later, an ice clutch is formed around the wire, and if the clutch's weight exceeds 200 kg per meter, the wire will break and someone will be left without light. The company Rosseti has its know-how to combat ice. A section of the line with icy wires is disconnected from the line, but connected to a direct current source. When using a direct current, the ohmic resistance of the wire can be practically ignored and currents, say, twice as strong as the calculated value for alternating current, can be passed. The wire heats up, and the ice melts. The wires discard the unnecessary cargo. But if the wires have repair couplings, then there is additional resistance, and then the wire can burn out.

Another enemy is high-frequency and low-frequency oscillations. The drawn wire of an overhead line is a string, which under the influence of wind begins to vibrate at a high frequency. If this frequency coincides with the natural frequency of the wire and the amplitudes are aligned, the wire may tear. To cope with this problem, on the lines are installed special devices - vibration dampers, having the form of a cable with two weights. This design, which has its own oscillation frequency, detunes the amplitudes and dampens the vibration.

With low-frequency oscillations, such harmful effect as "dancing of wires" is connected. When a line breaks (for example, due to the formed ice), there are oscillations of the wires, which go on a wave further, after several spans. As a result, five to seven supports constituting an anchor span (the distance between two supports with rigid fastening of the wire) can bend or even fall. A well-known means of combating "dancing" is the establishment of interphase struts between neighboring wires. If there is a spacer, the wires will mutually quench their oscillations. Another option is the use on the line of supports made of composite materials, in particular from fiberglass. Unlike metal supports, the composite has the property of elastic deformation and easily "win back" the oscillation of the wires, bending over, and then restoring the vertical position. Such a support can prevent a cascading fall of a whole section of the line.

The photo clearly shows the difference between a traditional high-voltage wire and a new wire. Instead of a wire of circular cross section, a pre-deformed wire was used, and the place of the steel core was occupied by a composite core.

Supports-Unicum

Of course, there are different kinds of unique cases related to the laying of overhead lines. For example, when installing supports in flooded soil or in permafrost conditions, conventional piles for the foundation are not suitable. Then screw piles are used, which are screwed into the ground like a screw to reach the most solid foundation. A special case is the passage of power transmission lines of wide water obstacles. They use special high-altitude bearings, which weigh ten times more than usual and have a height of 250x270 m. Since the length of the span can be more than two kilometers, a special wire with a reinforced core is used, which is additionally supported by the ship. This is how, for example, a transmission line is constructed across the Kama with a span length of 2,250 m.

A separate group of supports are structures designed not only to hold wires, but also carry a certain aesthetic value, for example, sculpture supports. In 2006, the company "Rosseti" initiated the project with the goal of developing support with an original design. There were interesting works, but their authors, designers, often could not assess the feasibility and technology of the engineering implementation of these designs. In general, it must be said that the supports in which the artistic design is embedded, as, for example, the support-figures in Sochi, are usually established not on the initiative of grid companies, but on the order of some third-party commercial or state organizations. For example, in the US popular support in the form of the letter M, stylized under the logo of the fast food chain McDonald's.

Via popmech.com & wiki

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.