Fuel Activator

- START

- EKOTYUNING-KIT

- SuperAquaCar

- Pulse

- UPG-2

- Activator Magnetic

- Fuel Activator

- Water injection (ECOMACS)

- HBO

- NanoVit

- V-Tech box

- EcoTop

- AirWing

- Anticoron AKOR

- Roher

- Ecotuning Oil

- Efficiency plus

- FFI MPG Supplements

- Zero filters (K & N)

- Lambda probe emulator

- Diesel particulate filter emitter

- Emulator of lambda probe and MAF

- Usefulness

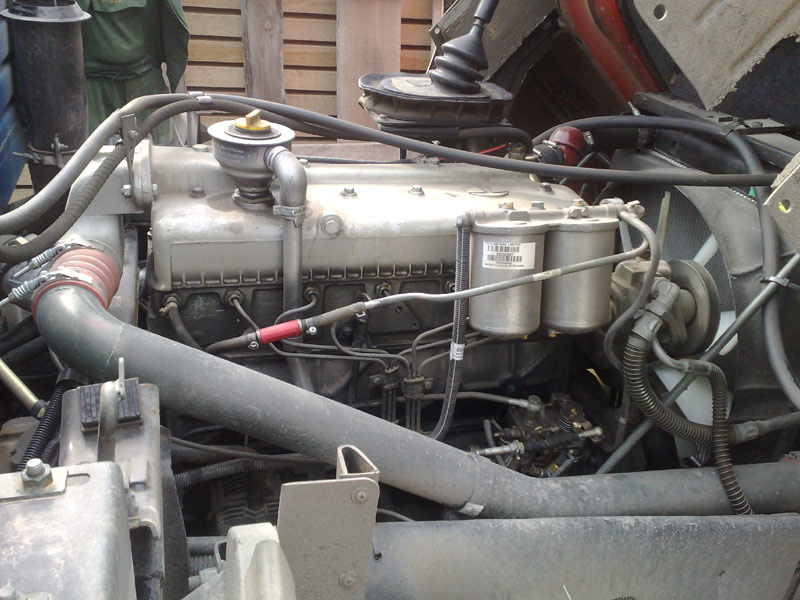

- A PHOTO

- BUY & CONTACTS

Fuel Activator - The device, developed on the basis of advanced modern technologies, can be installed on gasoline and diesel engines of heavy, medium and low power, with fuel consumption from 3 to 60 liters per 100 km.

The processing (activation) of the fuel before entering the combustion chamber of the internal combustion engine takes place in the channel of a fuel pipe with a variable cross-section. A positive effect is achieved at the molecular level in the channel volume of the fuel line with variable polarization by the magnetic field. Since an elementary liquid particle (molecule, ion) acts in a magnetic field, the Lorentz force tends to rotate it perpendicularly, then in the volume of a fuel line with variable polarization, resonant magnetostrictive effects arise that break hydrocarbon "chain fuel", leading the fuel structure to the state in which the oxidizing The combustion process proceeds much more efficiently, with a reduction in harmful emissions.

When researching at the booths of the design bureau for medium-power engines, when using the device in the fuel supply system of the forced automobile diesel SMD-23-07, the following results were obtained:

- To save fuel - 13-17%,

- Reduction of smokeiness - about 50%,

- Reduction of nitrogen oxide (NO2) emissions - 11-16%,

- Reduction of carbon monoxide emissions - 14-20%,

- Decrease in hydrocarbon emissions (HF) - 5-7%

The greatest effect is achieved when the device is located in close proximity to the executive body of the unit (in front of the carburettor, injector, sprayer). In this case, the effect of the greatest structural rearrangement of fuel molecules remains in preparation for effective combustion. Fuel, passing through the fuel line, fulfills the conditions of the Joule effect (with increasing deformation of the magneton, the magnetic permeability increases). As in any magnetostrictive effects, if there is a change in the dimensions in the volume of polarization, the change in the magnetization is inevitable. It is on this stretch and the magnetic tension is amplified - the condition of matching the Gillman effect. Diamagnetic filling is used to reduce the scattering of magnetic flux and to reduce external magnetic influences.

The fuel flow passes through 5 critical sections in a constantly compressing magnetic flux with an alternating field direction. Approximately 1/6 of the fuel flow receives a 3 "turn" by 180 ° and 5/6 of the fuel "turns" 4 times by 90 ° and one by 180 °.

Thus, in the proposed device, fuel preparation occurs just before the combustion process, the time of oxidation processes is determined mainly by the rate of the chemical reactions of fuel combustion. In turn, the rate of the course of chemical combustion reactions depends on the state of the hydrocarbon compounds.

An increase in the rate of chemical combustion reactions as a result of fuel reorganization at the molecular level increases the useful power of the ICE and, ultimately, increases the efficiency of fuel use, and also significantly improves the ecology of the exhaust.

The proposed device for preparing fuel before burning it, in this embodiment, performs the most effective destruction of "hydrocarbon chains" (hydrogen bonds) and keeps them in this state for the time necessary for the process of the most efficient combustion of fuel.

- Fuel economy 7 - 18%, whether it is gasoline or diesel fuel

- A noticeable increase in power and improved acceleration dynamics

- Extended engine life

- The possibility of using cheaper fuel with a lower octane number and avoiding problems associated with the use of low-quality gasoline

- Reduction of harmful emissions by 25-30%

- Increase engine's engine up to 50%

- Significant savings on car maintenance: replacing the spark plugs, injectors, valves and cleaning the injector / carburetor

- Easing engine start in winter

The activator is easily installed on any type of car, does not require additional maintenance, is not influenced by external factors and the environment.

Testing

The device was tested at the Main Specialized Design Bureau for Medium Power Engines (Kharkov).

All necessary parameters were determined in accordance with GOST 14846-81, including fuel and air consumption, as well as emissions of nitrogen oxides, carbon monoxide, hydrocarbons and smoke of exhaust gases. To determine the emissions of harmful substances, continuous gas analysis equipment was used. To determine emissions of harmful substances, continuous gas analysis equipment was used:

- Nitrogen oxides (NOx) - chemiluminescent gas analyzer 344 XL-01

- Carbon Oxide (CO) - infrared non-dispersive analyzer 121 DF

- Total carbohydrates (GD) - flame ionization detector 334 KPI03

- The smoke of the exhaust gases was determined by the Hartridge-MK-3M opacimeter.

The study was carried out by successively removing the adjusting characteristics for the set angle of the fuel injection advance at the engine speed of the diesel engine's N crankshaft of 1500 and 200 min-1 and the load characteristics at N = 1000, 1500 and 2000 min-1 at certain optimum angles for the specific fuel consumption at N = 1500 min-1 without the Activator and with the Activator. The range of load changes in the load characteristics was from idling to Ne Max.

The activator was installed in the fuel supply system after the fine fuel filter at the inlet to the high-pressure fuel pump.

The studies were carried out on diesel fuel in accordance with GOST 305-82.

As a result of the research, the following conclusions were reached:

1. The nature of the change in the setting angle of the fuel injection advance at the engine speed N = 2000 min-1 and N = 1500 min-1 has a more flat characteristic in comparison with the original version, and the values of the optimal angles are shifted by 1.5 and 2, respectively Deg.

2. The time and specific fuel consumption at the high-speed operation modes of the diesel engine N = 1500 min-1 and N = 2000 min-1 decreased by 13.5 and 13.2%, respectively, and at a diesel engine rotational speed N = 1000 min-1 - up to 17.55%, reaching a maximum value in the range of average loads.

3. At a frequency of rotation of the crankshaft of the diesel engine of the load and speed modes investigated, the smoke intensity decreased by an average of 20.7%, in the free acceleration mode by 22%

4. The emission of nitrogen oxides with exhausted diesel gases in comparison with the initial version decreased by 10.8 -16.3% in the entire range of load-speed characteristics studied.

5. The emission of carbon monoxide in the entire range of load-speed regimes studied was reduced by 13.74-20.14% in comparison with the original version.

6. The release of hydrocarbons with exhausted diesel gases in the entire range of load-speed regimes studied decreased by an average of 5.6%.

Conclusion

As a result of the studies, it was concluded that the use of the Activator leads to a decrease in the period of autoignition delay, reduces the rigidity of the diesel engine, increases the life of the GPG, reduces the toxicity of the exhaust gases. The use of the Activator makes it possible to significantly improve the hourly and specific fuel consumption rates, thereby increasing the technical, economic and operational characteristics of the diesel. Also, the use of the Activator can significantly reduce the smoke and emissions of carbon monoxide, nitrogen oxides and hydrocarbons in the entire range of loading-speed regimes, thereby improving the environmental performance of the diesel engine. The received parameters and results testify to high reliability and efficiency of the Activator, which allows to recommend it for use in any automobile engines.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.