Emulator of catalyst operation SK-02, SK-02a, SK-03, SK-06

- START

- EKOTYUNING-KIT

- SuperAquaCar

- Pulse

- UPG-2

- Activator Magnetic

- Fuel Activator

- Water injection (ECOMACS)

- HBO

- NanoVit

- V-Tech box

- EcoTop

- AirWing

- Anticoron AKOR

- Roher

- Ecotuning Oil

- Efficiency plus

- FFI MPG Supplements

- Zero filters (K & N)

- Lambda probe emulator

- Diesel particulate filter emitter

- Emulator of lambda probe and MAF

- Usefulness

- A PHOTO

- BUY & CONTACTS

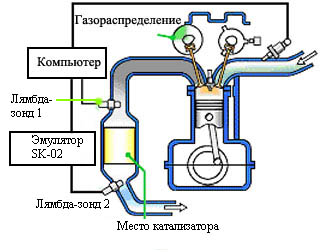

The emulator is designed to process the signal from the lambda probe according to the algorithm of the functioning catalyst.

At the input of the computer (electronic control unit), the already processed signal is delivered in the form in which it was with a working catalyst.

Thus, the ECU considers the catalyst to be in good order.

What does this device give:

- By reducing the resistance of exhaust gases, fuel consumption is reduced, saving up to 10%;

- An increase in power;

- The engine failure lamp (check) will not bother you anymore, the engine is running in normal mode;

- You do not need a catalyst, therefore, it will never fail.

Why the emulator?

The emulator will forever forget about the existence of an expensive catalyst, the cost of which is more than 1000 euros.

To do this, you only need to do some complicated work to knock out or remove the catalyst and install a catalyst emulator.

Why does the catalyst fail?

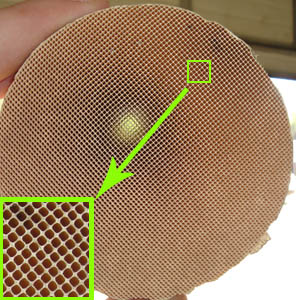

The catalyst is a device with small holes inside, in the exhaust system, which burns down part of the burnt fuel.

The main reason for failure of the catalyst in the CIS is the low quality of gasoline. Low-quality gasoline burns slowly, so the explosion occurs half in the combustion chamber, and half in the exhaust, above the catalyst surface. The catalyst is a ceramic structure with very thin and delicate walls, similar to honeycomb and in the case of detonation of gasoline over its surface, it begins to break down (crumble). Over time, it clogs itself and creates a barrier to the hot exhaust gases, as a result of which the engine loses traction and overheats. But this is not the worst thing. As already mentioned above, there is a barrier to the free exit of gases, hence the pressure of gases on the section between the engine and the catalyst increases substantially. Every time the engine is muffled, it stops in such a way that the valve timing system in any cylinder is in any case open. Excessive pressure instead of just flying out into the pipe, tearing off ceramics particles from the catalyst surface and throwing them through open valves back into the engine, onto the piston surface directly into the combustion chamber. The next time the engine is started, the ceramic dust is mixed with the oil on the cylinder walls, turning into a highly abrasive paste. In this case, irreversible - complete wear of all rubbing parts of the engine and complete failure of the unit as a whole - can occur. It is very important to diagnose the catalyst in time at the initial stages of destruction, rather than wait until the engine electronics failure lamp comes on. It is better and cheaper to resolve the issue immediately, without bringing the situation to a critical one. Due to the fact that the resistance to exhaust is created, the exhaust system is heated to red, in some cases it can lead to a fire.

Reasons for catalyst failure:

- Addition of additives to gasoline

- Poor fuel quality

- Incorrect fuel-air mixture (usually - failure of the lambda probe)

- Incorrect operation of the ignition system (misfiring)

- Mechanical damage to the catalyst

- Natural aging (during normal operation - service life up to 100 000 km)

New Catalyst |

Fused, clogged catalyst (From above stands a new one for comparison) |

How to determine if the catalyst is clogged up

1. Unscrew the oxygen sensor, screw in the manometer, and measure the pressure in the exhaust system. If the pressure exceeds 0.5 atm (Kg / cm2) at any of the motor operating modes, the catalytic converter is clogged.

2. Warm up the engine well (driving through the city-road) for half an hour, then take a thermo-gun (pyrometer) and check the temperature in front of the catalyst (right at the welding seam) and immediately after the catalyst (also in place of welding pipe and catalytic converter). If the temperature after the catalyst is lower or the same as before the catalyst, then the catalytic converter is clogged or does not work.

3. If something is ringing inside the catalyst, do not waste time, take urgent action.

The procedure for replacing (or knocking out) the catalyst on the emulator

1. Remove the catalyst;

2. Knock out its contents with a scrap;

3. Send (not free) the inside of the catalyst to us;

4. Instead of a catalyst, it is better to install a flame arrester. If you install an empty case from the catalyst, then the exhaust sound is likely to become louder;

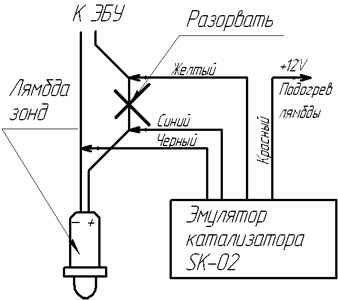

5. Produced according to the scheme in the figure after removal of the catalyst. The emulator is connected to the 2nd lambda, which is located behind the catalyst. Power emulator is made from the heating circuit lambda probe or ignition coil through the red wire (power must be supplied only when the ignition is switched on).

The yellow and blue wires are connected to the break of the signal cable of the lambda. The voltage on this wire lies in the range from 0.1 to 1 Volt.

Information

Instruction SK-02

The instruction SK-03 (Works without lambda probe)

In order that you would get positive results from emulators in 100% of cases, we broke emulators into 2 categories by type of cars.

The catalytic converter SK-02 should be installed on cars: Audi, Volkswagen, Hyundai, Subaru, Miitsubishi, Plemouth-Neon, Pontiac, Mazda, Infiniti, Skoda, Volvo, UAZ Patriot, Honda before 2005, Kia before 2005, Opel before 2005, Toyota Until 2003, SAAB before 2005, Lexus until 2004, Mercedes Benz until 2005, BMW until 2004.

The catalyst emulator SK-06 is installed on all other cars.

Warranty 1 year from the date of sale.

The test period is 14 days.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.