Replacing the particulate filter (FAP / DPF) with the SK-05 emulator

- START

- EKOTYUNING-KIT

- SuperAquaCar

- Pulse

- UPG-2

- Activator Magnetic

- Fuel Activator

- Water injection (ECOMACS)

- HBO

- NanoVit

- V-Tech box

- EcoTop

- AirWing

- Anticoron AKOR

- Roher

- Ecotuning Oil

- Efficiency plus

- FFI MPG Supplements

- Zero filters (K & N)

- Lambda probe emulator

- Diesel particulate filter emitter

- Emulator of lambda probe and MAF

- Usefulness

- A PHOTO

- BUY & CONTACTS

The emulator is designed to completely remove the particulate filter on diesel engines with the Common rail injection system. Diesel cars meeting the requirements of the Euro-4 standard and equipped with particulate filters appeared in 2001. The Euro - 4 standard itself has been operating in Europe since 2005, the euro - 5 standard has been operating in Europe since 2009. This device allows you to reproduce all the signals associated with the particulate filter.

The advantages of a FAP / DPF emitter:

- - You save much on replacing the diesel particulate filter (The cost of the filter starts at $ 1000);

- - You get some power increase due to reduction of resistance to exhaust gases;

- - Reducing fuel consumption by changing the regeneration period;

- "The particle filter will never bother you again;

- - The control unit does not open when installing the emulator.

Symptoms of a defective particulate filter

The driver usually learns about the existence of a particulate filter (FAP / DPF) after the corresponding indication appears on the instrument panel. The failure of a diesel particulate filter usually entails a reduction in power and an increase in fuel consumption, smoke, unstable operation of the diesel engine. When reading the fault codes, error code P2002 "Low FAP / DPF efficiency" usually appears.

The principle of the particulate filter (FAP / DPF)

Reducing the amount of harmful emissions is achieved both due to the design features of the engine with the common rail system, and using a particulate filter. On most modern diesel vehicles, the particulate filter is structurally integrated with an oxidation catalyst. Oxidizing catalyst is located in the front of the filter. In this way, the functions of both the FAP / DPF filter and the catalyst are performed.

The particulate filter detains soot particles that are contained in the exhaust gases. The catalyst function consists in the oxidation of hydrocarbons (afterburning of not burnt fuel), as in a gasoline engine.

For the correct operation of the diesel particulate filter, a lot of sensors and functions that are not present in the gasoline engine are involved in the car's control system.

- Dashboard

- Electronic control unit

- Air flow sensor (MAF)

- Diesel engine

- Temperature sensor in front of the turbine

- Turbine

- Temperature sensor in front of diesel particulate filter

- The oxygen sensor (lambda)

- Diesel Particulate Filter (FAP / DPF)

- Differential pressure sensor in particulate filter

- Temperature sensor after particulate filter

The FAP / DPF filter is usually installed in the immediate vicinity of the turbine.

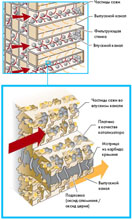

The filter is a ceramic matrix enclosed in a metal casing. It is permeated with inlet and outlet channels. Filter walls are made of porous silicon carbide, coated with auxiliary substances. The walls trap particles of soot, and the gas passes through the channels freely.

Regeneration

In the process of work, a soot filter accumulates in the soot filter, which prevents the free exhaust gas outlet. Therefore, from time to time, it is necessary periodically to prevent the filter from soot. The process of releasing the filter from soot is called regeneration.

There are active and passive regeneration of the diesel particulate filter. The regeneration process for the driver is not noticeable.

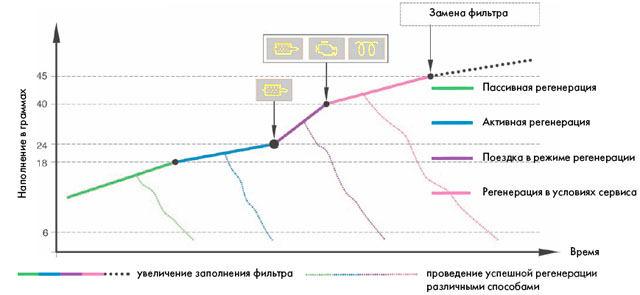

Kinds of regeneration depending on the filling degree of the FAP / DPF filter

Passive regeneration

With passive regeneration, the soot burning process is performed continuously and without intervention in the engine management system. Passive regeneration is possible mainly at engine loads above the average when the temperature of the exhaust gases in the filter reaches 350 degrees and above. With passive regeneration, chemical reactions of the conversion of soot to carbon dioxide occur. Acceleration of these reactions is carried out using a layer of platinum, which acts as a catalyst.

Active regeneration

The control unit constantly monitors the degree of filter clogging by means of temperature sensors, differential pressure and air flow. When the critical degree of debris is reached, the control unit starts active regeneration.

The essence of active regeneration lies in the artificial increase in temperature in the soot filter to 600 degrees or more. Achieving such a temperature is possible with directional control of the engine.

To increase the temperature of the exhaust gases, the control system produces the following actions:

- The recirculation of exhaust gases is stopped to raise the combustion temperature of the fuel;

- The additional portion of fuel is injected when turning the crankshaft by 35 degrees. After TDC;

- By means of a throttle заслонки air supply in the engine decreases;

- Another additional fuel injection can be made, while the fuel does not ignite in the cylinder, but burns directly in the FAP / DPF filter;

- The boost pressure is maintained at such a level that the driver could not notice the transition to the regeneration mode.

Warranty 1 year from the date of sale.

The test period is 14 days.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.