HBO - Gas Balloon Equipment

- START

- EKOTYUNING-KIT

- SuperAquaCar

- Pulse

- UPG-2

- Activator Magnetic

- Fuel Activator

- Water injection (ECOMACS)

- HBO

- NanoVit

- V-Tech box

- EcoTop

- AirWing

- Anticoron AKOR

- Roher

- Ecotuning Oil

- Efficiency plus

- FFI MPG Supplements

- Zero filters (K & N)

- Lambda probe emulator

- Diesel particulate filter emitter

- Emulator of lambda probe and MAF

- Usefulness

- A PHOTO

- BUY & CONTACTS

We offer gas equipment for cars and trucks and a full range of professional services related to them.

And in all European countries, the popularity of a system depends on the manufacturer's warranty on its product, on access to service and technical support from their representatives, on the quality of the equipment offered, and its prevalence in the region.

There are several types of gas-cylinder equipment systems in the HBO market. For their classification, the term "generation" is used.

Each generation works by its own principle.

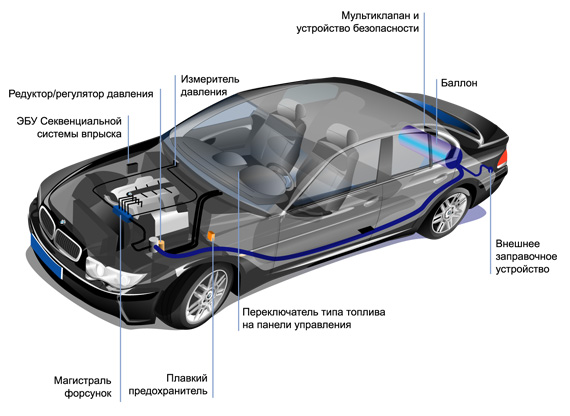

To begin with, it must be said that the difference in systems refers to the elements of the gas supply, and also to the control system. The remaining components (balloon, gas pipes, refueling device) are identical for all generations.

1 generation HBO - Ejector with register (with electric or vacuum reducer). The simplest scheme for supplying gas to the engine is equipped with an ejector reducer with electro or vacuum control. Further, a simple mechanical dispenser and mixer. The gas is fed to the intake manifold to the common receiver.

2 generation HBO - Ejector with lambda control. The basis of the system is the same as in the first generation, only instead of a simple mechanical dispenser, a stepping motor is installed, the signal to which comes from the controller. Input signals for it are the signal of the lambda probe and the throttle position sensor. It also has a name, a lambda control system.

3 generation HBO - Gas injection does not use the gas injection strategy as the basis for calculating gas injection. This system uses a pressure reducer with excess pressure. Gas is fed separately into each cylinder. Dosed by a special metering device with a stepper motor. Do not use the gasoline injection strategy to calculate the required amount of gas.

4 generation HBO - Gas injection, serial. When working on gas, the engine is still controlled by the petrol control unit, only the signal for the gas injectors is the input signal for the gas control unit. The gas control unit makes its own corrections, taking into account also the temperature of the gas, injectors, gas pressure and controls the electromagnetic gas injectors. Those. The gas control unit is a superstructure and all standard engine sensors are used during operation.

Read more:

Distributed injection of the vapor phase of gas, as an alternative fuel system for internal combustion engines, conditionally called the "4th generation HBO system".

Systems of the 4th generation have long and quite been widely represented in the market of HBO systems around the world, including in Ukraine. They are used in adaptation of vehicles, for use as an alternative fuel gas mixture of propane-butane or natural gas methane. They are widely used in all injection cars, including those with turbo-superchargers equipped with OBD, OBD II, EOBD self-diagnosis systems and comply with strict European exhaust emission standards EURO -3, -4, -5.

The principle of operation of the 4th generation HBO applies equally to all manufacturers of these systems. In all, it is the same.

Liquefied gas, coming from the cylinder through the gas-fuel line, through the primary purification filter element (fuel filter of liquid phase of gas), enters the reducer-evaporator. Due to the fact that the gearbox is connected to the engine cooling system and is heated from the cooling water passing through its internal water cloak, it acts as a gas evaporator, and its internal mechanism regulates the pressure and produces the vaporized gas flowing further towards the engine of the car.

Under the influence of heat transfer of the cooling liquid, the liquid gas passes from the liquefied state to the gaseous state. Further, from the reducer through the filter element of fine purification of the vapor fraction of gas (or otherwise - the vapor phase filter of gas), the vapor gas through the fuel hoses is fed to the fuel rail in which the gas nozzles are installed.

The vehicle's on-board computer, based on the information that the designers put in the fuel card of this car, sends certain impulses (signals) to the petrol injectors, which are necessary to create a correct fuel mixture. These signals are intercepted by the electronic control unit (ECU) of the HBO system, to carry out the necessary correction in the adaptation of the gas mixture with respect to the fuel-fuel card. After that, the processed signals are sent further, but already to the gas injectors.

The received impulses open the gas injectors, and allow them to supply the required amount of gas to obtain a correct air-fuel mixture. Injecting portions of gas through the "gas jets", which are installed in the intake manifold, in the immediate vicinity of the gasoline injectors.

This description, briefly presented in this way, it is possible, to whom it will help to understand the strategy of HBO of the 4th generation, if earlier it was not fully understood.

Dutch, Polish, Italian, Lithuanian, Russian, Turkish, Korean, Chinese manufacturing companies have saturated the world market of 4th generation HBO systems, their number today has far exceeded the figure of 40.

The different marketing strategies used by the manufacturers of these systems result in a great choice for future customers. Some companies represent complete sets of model and universal systems on the market. Others, give the opportunity, to compose the most necessary complete set of a universal system, using for this purpose elements from third-party manufacturers. All this in the first place gives companies the opportunity to occupy a certain niche in the market of HBO systems.

And in all European countries, the popularity of a system depends on the manufacturer's warranty on its product, on access to service and technical support from their representatives, on the quality of the equipment offered, and its prevalence in the region.

Our company serves most of the systems presented in the Ukrainian HBO market.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.