Efficiency plus

- START

- EKOTYUNING-KIT

- SuperAquaCar

- Pulse

- UPG-2

- Activator Magnetic

- Fuel Activator

- Water injection (ECOMACS)

- HBO

- NanoVit

- V-Tech box

- EcoTop

- AirWing

- Anticoron AKOR

- Roher

- Ecotuning Oil

- Efficiency plus

- FFI MPG Supplements

- Zero filters (K & N)

- Lambda probe emulator

- Diesel particulate filter emitter

- Emulator of lambda probe and MAF

- Usefulness

- A PHOTO

- BUY & CONTACTS

New integrated technology

A new integrated technology to significantly improve the performance of piston internal combustion engines, units and mechanisms of automotive engineering, aviation, ships and ships, diesel locomotives, and engine-electric generators.

The method of forming superhard surfaces of friction pairs, of the 14th accuracy class, in order to significantly reduce noise and repeatedly increase the survivability of machines, units and mechanisms on ships and navy vessels, for use on civil fleet vessels is approved by the "Permission of the Marine Register" Sevastopol, and Is also allowed for use in the industrial sector.

Tasks of integrated technology

Form a superhard, high-precision surface of metal friction pairs in the operation of mechanisms. More than 1500 (one thousand five hundred) times to reduce the coefficient of friction in the nodes and mechanisms. Dozens of times reduce the peak values of dynamic loads and prevent the build-up of friction pairs in the metal, and also eliminate cavitation from mechanical causes on the walls of the cylinder liners. To block effectively the penetration of gases through the thermal gaps in the locks of the compression rings of the internal combustion engine, making the compression stably nominal and independent of the magnitude of these gaps and temperatures. To increase the torque at low engine speeds (in the world practice of engine building there are no analogs). As a result of significant improvements in technical and operational parameters, in general, categorically improve environmental performance.

According to experts, the application of the method of this technology for ICE and transmission of KAMAZ trucks (quarry dump truck) brings significant profit due to improved techno-economic performance of ICE and mechanisms:

- Reduces fuel consumption

- - at idle turns by 70-80%;

- - for small and partial loads by 30-50%;

- - with power regimes of 20-35%;

- - an average of 40%;

- Increases torque at low revs by 20-25%;

- Increases the engine power by 25-35%;

- Reduces the oil consumption in the fumes by 95-98%;

- Provides an increase in the resource ICE without overhaul up to 10 times;

- Reduces the coefficient of friction in the nodes and mechanisms in 1500 (One thousand five hundred) times .;

- Guarantees against wear during "Cold start-up" during the entire service life;

- Significantly reduces noise and vibration;

- Normalizes and stabilizes the compression throughout the life of the piston engine group;

- Guarantees easy start of the engine at sub-zero temperatures;

- Significantly improves environmental performance (for thermal pollution including).

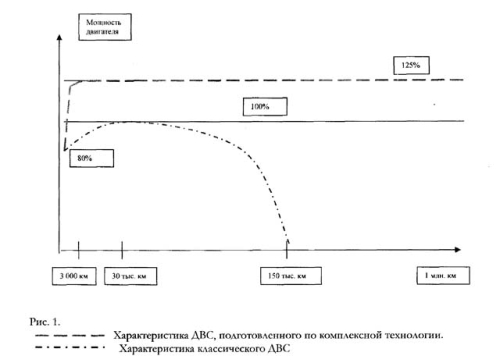

Modernized with this technology new or updated ICE exhibits the following characteristics:

- - Up to 3 000 km of mileage improvement of characteristics to "supernorm";

- - from 3 000 km to 1.5 mln km of run, stable retention of the achieved characteristics.

As a whole, the practice of normative exploitation of domestic engines is as follows: up to 30 thousand km. The engine runs better and better, from 30 thousand km. Up to 70 thousand km., For reasons of friction, it begins to gradually wear out and at the end of this period it is desirable to change the rings. Further, the ICE wears out irreversibly and to 150 thousand km. Mileage requires a major overhaul with a complete replacement of the cylinder-piston group. Complex technology prevents wear from friction during the stated rate of the motor resource, and also makes compression independent of the thermal and power modes of the ICE. Even the "respectable" engine in all terms and at the end of the service life still works flawlessly, quietly, constantly powerful and smokeless when it employs a system of integrated technology.

Characteristics of power, fuel and oil consumption under the integrated technology system

It is known that: the smaller the gap in the hot state between the piston head above the first (fire) ring and the cylinder, the greater the throttling of gas in this gap and the better the operating conditions of the rings. So, with a clearance of 0.05mm and a gas temperature in the upper part of the gap of 800 degrees C, the temperature of the gas is reduced to 400 degrees C at a distance of 20mm from the top, and only to 700 degrees with a gap of 0.5 mm. On the piston rings varies both from the distance to the ring and from the pressure of the gas in the cylinder. If you take the pressure in the cylinder of the ICE of the car for 100%, then the pressure acting on the I ring will be 75%, for II 17%, and for III 7% (at nominal gaps).

Prevention of gas breakthrough into the crankcase is evidently due to a decrease in pressure due to gas throttling during passage of the labyrinth tunnels and gaps formed by the rings, which is a cost and is not an effective expenditure of the energy of the glowing gases in the engine cylinders. On super-propulsion marine engines, to prevent the gas from bursting into the crankcase, especially when the piston of the TDC area passes at low speed under load, up to seven compression rings are set (the same is the question of friction).

The system of complex technology constructively blocks gas at the level of the upper (fire) ring and, regardless of the values of the gaps of the rings, effectively returns to the crankshaft up to 24% of the explosion energy in the combustion chamber of the vehicle's internal combustion engine. Such methods are provided with indicators for increasing torque at the "bottoms", increasing power, reducing fuel and oil consumption (in fumes), and in general - determining environmental indicators of the level of European standards throughout the life of the vehicle.

Vitality of ICE for sport, motor life 1000000 km. Serial internal combustion engine

If the engine is significantly boosted, the increased loads in the bearings of the KShM can lead to the destruction of the oil wedge in it, i.e. To increased bearing wear, metal setting, melting of bearings, etc. The load on the bearing depends, both on the circumferential speed of the bearing, which determines the friction values, and on the dimensions: the length of the bearing and its diameter at a given pressure on the piston. The energy costs for overcoming frictional forces in the main ICE nodes are: CPG - 11.5%; GRM - 2,7%; Crank - 3% of the power of the car engine. Complex technology, unlike other methods of forcing ICE, reduces the coefficient of friction by 1500 times, and as a whole - increases the engine power by 25-30%, keeps the geometry of the parts and, as a result, the optimal size of the piston-cylinder gap for the entire life of the motor, and Its efficiency allows the installation of compression rings with increased thermal gaps. It is advisable to increase by 0,2 mm from the nominal, the gap of the upper (fire) ring in order to redistribute the pressure and temperature, thereby significantly softening the working conditions of the compression rings and to prevent the thermal wedge of the GPG in case of overheating of the internal combustion engine. Such are the possibilities of integrated technology.

It is possible to keep the internal combustion engine in a stably-perfect state, repeating the indiscriminate recovery of mechanisms through 150 thousand km. Mileage (300,000 km for high-tech ICE), etc. The use of integrated technology universally solves the problem of 1 million km. Mileage and above, for a new ICE.

Improving the performance of an aircraft piston engine

Thermal clearances of piston rings are carried out taking into account conditions from thermal jamming at the forced mode of operation of ICE. Aviation ICEs at extreme power modes withstand significant heat flux, which can reach 2500 degrees. Therefore, the set of high altitude is carried out in stages in several lifts, in order to save the engine from thermal destruction. With decreasing loads - nominal, medium, small - power modes, the heat flux decreases and, as a consequence, this determines a noticeable increase in the thermal gaps of the piston rings, which leads to breakthrough of gases into the crankcase and loss of power in a well-prepared reciprocating engine. In this case, through the increased thermal clearance of the piston rings, oil from the crankcase enters the combustion chamber. During parking, when the ICE is not warmed, from the lower cylinders, through the thermal clearances of the piston rings, there is also a significant loss of oil (oily soil in the parking lot, steering lanes). The use of complex technology allows to block effectively the breakthrough of gases into the crankcase and the loss of oil, resulting, as a result, from the increased in the standard thermal clearance of the piston rings of the aircraft engine.

When the piston engine is operating, the heat from the piston is removed: 20-25% - through the oil in the crankcase and 75-80% - the contact piston -> the rings -> the cylinder. In a well-engineered ICE, due to the mikro-relief of the surfaces of the friction pairs, from 100% of the geometric contact area of the parts, 3 (three)% of the area actually touch, and in the worn out ICE ("barrel", ellipse in the cylinders) and this is less. This parameter categorically determines the limit of the heat flux density of the cylinder, which is withdrawn from the piston to the wall. The use of complex technology forms a smooth-wavy profile of the surfaces of friction pairs of the 14th accuracy class and creates a real contact spot of 16 (sixteen)%. Increasing over five times the real contact area increases the possibility of heat dissipation, which protects the piston, rings, and oil wedge from overheating. Such a surface of the parts of rubbing pairs is characterized by some properties: an abnormally low coefficient of friction, superhardness, strength, keeps the geometry of parts, high wear resistance, high thermal conductivity, prevents the formation of nitrogen oxides (NOx) in the celinders by reducing their quantity by 80-90%, does not corrode , Dielectric, withstands a temperature of 3500 degrees C. It guarantees the surface from thermal destruction during afterburnings.

Elimination of cavitation on the outer walls of cylinders and conditions of "hardening" in the metal of friction pairs

Vibrations of cylinder liners under load form cavities of rarefactions in a cooling liquid, where cavitation bubbles are formed, when collapsing in microzones, pressures up to 600 atmospheres arise. And temperatures up to 1200 degrees C (microexplosion) and clusters (microparticles) of metal break out from the outer surface of the sleeve, microcracks are formed, and then a surface rupture.

The system of complex technology instantly redistributes the energy of elastic deformation in the metal of friction pairs, reducing the peak values tenfold, that is, the vibrations of the walls of the cylinders are smoothed out and cavitation is prevented. In the same way, the critical deformation moments of the crystal lattice are eliminated, which form a "hardening" in the metal of friction pairs of knots and various mechanisms (ICE, reducers, gearbox, SHRUS, etc.).

Advantages of using complex technology on diesel engines and supercharged diesel engines, as well as gasoline internal combustion engines during launches

The difficulties of starting at low temperatures are well known. The most difficult to solve is the problem of self-ignition of fuel in diesel engines. Low initial charge temperature, and for supercharged engines - besides low (E) compression ratio, do not provide a sufficiently high compression temperature. The cold walls of the cylinders remove heat from the compressed charge, and the gaps in the locks of the compression rings can nullify the compression, catastrophically reducing its temperature. At a compression ratio of 13 (very low for an atmospheric diesel and high enough for a supercharged diesel engine), the compression temperature reaches 630 degrees C under full load conditions, but is significantly lower in partial load modes when the turbocharger has a small or even zero capacity. A naturally-aspirated diesel under the same atmospheric conditions at a compression ratio of 16 provides a compression temperature of 720 degrees C. It is obvious that the diesel with a supercharged start-up mode does not work, and as a result, the compression temperature is very low.

The use of complex technology makes the compression independent of the size of the gaps in the locks of the compression rings and provides a reliable increase in the compression temperature required for the successful launch of the diesel engine. The launch of a conventional gasoline engine can be called easy and problem-free, but by enriching the mixture for start-up and warm-up (at the same time, fuel consumption is 2-3 times, ecologically dirty exhaust, low engine power). Applying an integrated technology, these disadvantages are largely eliminated, since there is practically no need to enrich the mixture for start-up and warm-up.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.