FUEL FROM WATER

- START

- EKOTYUNING-KIT

- SuperAquaCar

- Pulse

- UPG-2

- Activator Magnetic

- Fuel Activator

- Water injection (ECOMACS)

- HBO

- NanoVit

- V-Tech box

- EcoTop

- AirWing

- Anticoron AKOR

- Roher

- Ecotuning Oil

- Efficiency plus

- FFI MPG Supplements

- Zero filters (K & N)

- Lambda probe emulator

- Diesel particulate filter emitter

- Emulator of lambda probe and MAF

- Usefulness

- A PHOTO

- BUY & CONTACTS

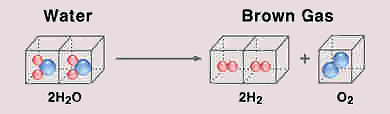

From water, HHO gas (it's 2 molecules of hydrogen and one molecule of oxygen, it's also called Brown's gas), which is combustible, is extracted very easily and in a simple way, and when the fuel is added to any fuel, whether it is gasoline, diesel or gas, the efficiency of the engine increases. At the same time, fuel economy reaches 25% -65% (according to statistics, an average of 30-40%), and the resource of the engine only increases due to the fact that during combustion, water again (in scant amounts), which is a unique natural solvent saves your engine From carbon deposits, as well as improves the heat exchange between the seat and the valve, the detonation and ignition firing are reduced, i.e. The load on the entire crank mechanism is reduced to a large extent. Also, due to a decrease in fuel consumption, the service interval of fuel injectors increases.

Brown gas is the most perfect fuel for our vehicles. It comes from water (that is, hydrogen and oxygen), as well as pure hydrogen. The exhaust produces water vapor.

Thus, the use of Brown gas helps to solve a very important environmental problem for us. From this point of view, Brown gas is an ideal fuel for cars of the future.

Why is Brown gas - like fuel, better than pure hydrogen?

At present, the environment is experiencing serious problems, and one of them is the loss of atmospheric oxygen. Its content in the air becomes so low that in some regions this poses a threat to the very existence of man. The normal oxygen content in the air is 21 percent, but in some regions it is several times lower! If we do not take action, then in the end, a decrease in the oxygen content in the air will affect each of us

Brown's gas, obtained by electrolysis, can supply oxygen to the atmosphere, while other technologies either do not affect the atmosphere in any way (like using pure hydrogen or fuel tanks) or contaminate it (as with fossil fuel). Therefore, we believe that this technology should be selected in the near future to provide fuel for vehicles.

Brown gas is also called: brown gas, HHO gas, water gas, hydrogen, dihydroxide, hydroxide, green gas, gas klein, oxyhydrogen.

Each liter of water expands to 1,866 liters of flammable gas. You do not need to carry a gas cylinder with you, but only a liter of water in the container under the hood! It can last for several months.

The function of hydrogen is the intensification of combustion processes in combustion engines. This is due to the fact that the temperature of hydrogen burning is higher than the combustion temperature of traditional fossil fuel, and the rate of ignition is almost a thousand times greater. Therefore, now unburned fuel, instead of burning out in the catalyst and flying into the atmosphere, will burn where it should - in the combustion chamber. By installing our system, you not only save fuel, but contribute to the preservation of the environment.

The system "SuperAquaCar" , produced by our company, consists of an electrolyzer (electrodes made of special stainless steel with special stainless steel, specially prepared), a circulation tank, a water seal or separator, a control system - a wideband current modulator (PWM) and a fuel mixture optimizer For injector cars). The method of gas separation is based on the phenomenon of water electrolysis. The capacity of the electrolyzer is from 1 l / min at 15 A. The circulation tank is designed for high-quality separation of gas from water, as well as supplying the gas generator with electrolyte.

In the electrolytic cell, an electrochemical reaction proceeds with the release of hydrogen and oxygen (Brown gas) from a special electrolyte consisting of distilled water and a catalyst. The chemical formula of the catalyst is such that it is not released with gas, but remains in water. You add only distilled water (as in the battery). The formed gas leaves the channel from the upper connection of the electrolyzer and is sent to a separate tank - the circulation tank . From there, follow through the water gate or separator (where additional purification from moisture is carried out) into the air collector and then into the combustion chamber. Also, from the circulation tank, water flows through the second channel back to the electrolyzer . Thus, the liquid circulates through the system. Under such a scheme, the electrolyzer must be placed below the circulation tank . The gas production control is performed by the current modulator depending on the crankshaft speed. The current modulator is an intelligent electronic device. Thanks to a special method of modulating the current, the maximum system performance is achieved. It also provides for a reduction in energy consumption and gas production with reduced crankshaft speed, this function prevents the discharge of the battery and unloads the electric generator of the car. On modern cars, reducing idle power consumption also results in a slight reduction in fuel consumption, since power generation is accompanied by an increase in fuel delivery to the engine, which is used to maintain the rated speed of the crankshaft. Since the combustion process with Brown gas improves, for maximum fuel economy in the engine, it is desirable to supply a leaner mixture in comparison with the conventional mode without compromising power. In this regard, we have developed an optimizer for the ratio of fuel-air mixture . The optimizer helps to bring the engine to the optimum mode when working with Brown gas, so that the maximum possible economy can be achieved. On injector cars, it is connected to the injector to obtain information about the engine speed, to the MAP or MAF sensor and to the lambda probes . Its function is to show the ECU a / m that the air comes in less than real and that the mixture is rich. Thus, we deceive the brain of the car so that it reduces the fuel supply. On modern diesel engines with ECU, the optimizer is also connected to the CKARTA - Sensor to deplete the mixture. On diesel engines with mechanical adjustment, it is necessary to deplete the mixture through adjustment of the fuel equipment. This applies to cargo vehicles.

Completeness:

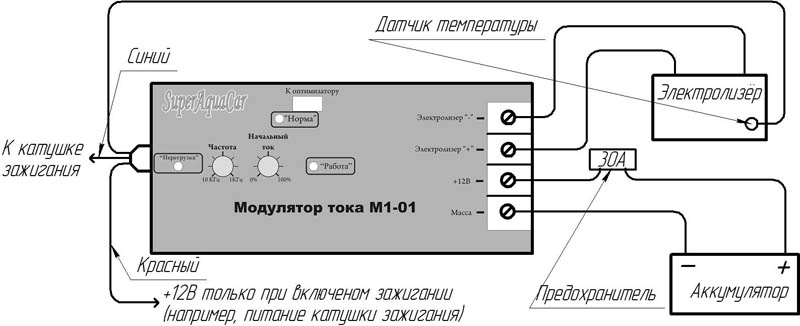

Description of the current modulator

The modulator provides adjustment of the current consumption of the gas generation system of the brown gas and the gas outlet. This makes it possible to unload the electric generator without compromising the efficiency of the system, especially at idle speed of the engine. Due to more rational use of energy for electrolysis, it becomes possible to use electrolyzers with higher gas output.

Also, when working in conjunction with the optimizer, the Modulator allows controlling the mixture formation depending on the engine operating conditions and the amount of gas produced.

Thanks to the application of the modern approach to modulator design, the conversion of electrical energy is made with an efficiency of 99.9%, which allowed to minimize the heating of the unit at rather high currents.

Two types of modulators are available: with and without a built-in current sensor. The modulator with the sensor is rebuilt so that under any conditions the current is limited to 25A. When coordinated, modulators with a working current up to 50A can be supplied. A modulator with a current sensor makes it possible to stabilize the current (and hence the production of gas) even with a strong change in the density of the electrolyte.

When the cell is overheated, protection is provided. If the temperature reaches a value of 670С - the current through the cell is limited. When the temperature exceeds 770С, the supply to the electrolyzer is not supplied. Also, protection is provided for overheating of the modulator elements.

The presence of frequency adjustment allows you to adjust the electrodes of the electrolyzer in resonant mode, which allows to increase the yield of the gas of brown to 20%.

Specifications

Current limit threshold, A 25

Supply voltage, V 12 or 24

Frequency range of the modulator, KHz 1 ... 8

Range of automatic regulation of power consumption and gas output,% 30 ... 100

The range of automatic regulation of power consumption when the maximum operating temperature of the electrolyzer is exceeded,% 0 ... 100

Protection temperature of cell protection, оС 77

The temperature of the protection operation when the internal components of the modulator are overheated, oC 100

Threshold of overcurrent protection over peak current, A 35

Frequency adjustment is

Connection scheme of the current modulator

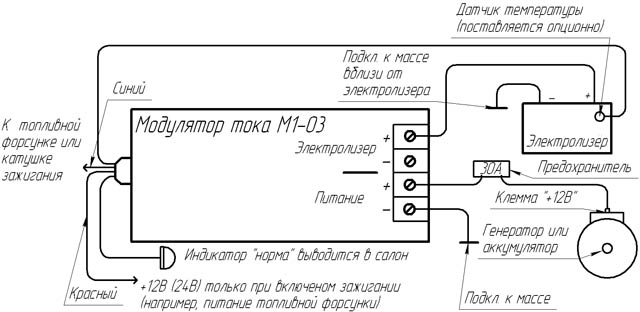

Description of current modulator (PWM) M1-03

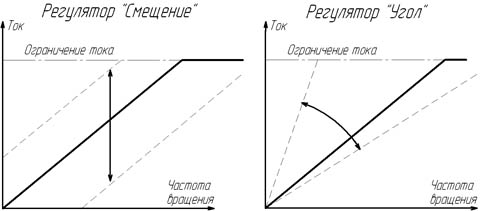

The M1-03 modulator is an improved modification of the M1-02 modulator and is designed to control the process of electrolysis, it provides adjustment of the current consumption of the system and the gas outlet. This allows to unload the electric generator without affecting the efficiency of the system. Also, when working in conjunction with the optimizer SD-03, the modulator allows controlling the mixture formation depending on the engine operating conditions and the amount of gas produced. Modulators have the ability to adjust the operating frequency, which can also be used to achieve the best results.

The current modulator M1-03 has a connector for external control, which allows to combine several modulators in a single system. This system can work on the necessary algorithm.

The modulator (PWM) with current sensor M1-03 is built in such a way that the limiting current is selected by the tuner and lies in the range of 5 ... 35A. The modulator has an integrated current sensor that allows stabilizing the current (and hence gas production) even with a strong change in the density of the electrolyte.

When the cell is overheated, protection is provided. When the temperature exceeds 77 ° C, the supply to the electrolyzer is not supplied (optional). Also provided protection when the modulator is overheated (110 ° C).

In the complete set with the modulator the portable indicator light "norm" is supplied, which duplicates the indicator on the modulator and is displayed in the car interior. This indicator indicates normal operation of the system (if the current and gas production can be maintained within a specified range)

Specifications of modulator M1-03

Limit of current limitation (limiting current), A 5 ... 35 (adjustable)

Operating frequency of the modulator (adjustable), KHz 1 ... 3

Range of automatic regulation of power consumption and gas output,% 0 ... 100

Possibility to combine modulators and external control Yes

Maximum operating temperature of the electrolyzer (protection threshold), оС 77 (Optional)

Protection against overheating of the modulator housing, оС 110

Output current stabilization

Protection against short circuit in the cell Yes (95A)

Operating voltage, V 10 ... 28

Built-in power filter Yes

Indication of the density of the solution (Indicator "norm") Is

The threshold current of the "standard" indicator (solution density indicator), A 12 or 25 (switchable)

Knock Sensor Sensitivity Adjustment Yes (Automatic)

Ability to adjust the current value depending on the speed

Connection scheme of the current modulator M1-03

Instruction M1-03

Optimizer for the proportion of fuel for injectors

As is known, when introducing additional working medium into the engine (water, alcohol, Brown gas), in order to obtain the effect of maximum economy, it is necessary to optimize the amount of gasoline supplied to the engine. We produce a three-channel optimizer for the ratio of fuel and air to the injector engines.

Universal fuel ratio optimizer for SD-02 injectors

Universal fuel ratio optimizer analog 3-channel (2 lambda and 1 DMR channel) for the injector engines. Supports zirconium and titanium (broadband) lambda probes The advantage of this optimizer is that the connection to the lambda probes is done without stripping the wires.

The optimizer is a complete electronic device that can correct signals from car sensors in a certain way. The optimizer can work on three channels - 2 channels of lambda control and one channel of the air flow sensor (DFMS). The signals are corrected so that the device has no effect on the DMRV signal when the engine is idling - this avoids a number of problems at idle.

The optimizer has two modes of operation:

- 1. Emulator mode - simulates signals from the lambda probe. In this mode, the system can operate even with a faulty oxygen sensor;

- 2. Lambda correction mode - the lambda coefficient shifts to -0.2 relative to the stoichiometric composition (20% conviction). The degree of correction is adjustable.

Optimizer for the proportion of fuel for injectors SD-03

It is an advanced optimizer SD-02. Improvements have touched on the algorithms of working with the DMRV. The SD-03 optimizer does not influence the DMRV signal at idle speed of the crankshaft and transient operation of the engine.

This optimizer can be used in installations of gas-balloon equipment of the 4th generation as an emulator of zirconium and broadband lambda probes. This will put out the engine's emergency operation indicator "Chek Engine".

Processor optimizer (EFIE) fuel proportions for SD-04 injectors

The fuel supply is controlled by correcting the signals from the oxygen sensors (lambda probes) and the mass air flow (mass flow sensor) sensor according to the program that the user determines. Absolutely all oxygen sensors of DMRV, and absolute pressure are supported.

The optimizer is equipped with software that allows you to connect it to a computer, read and write all parameters in real time, read fuel consumption, make adjustments without stopping the engine. Provides data output to the graphs. It is possible to store and record 3-dimensional sensor correction tables (MAF, MAP).

The optimizer provides two modes of operation: "simplified" and "advanced".

In the simplified mode, the user defines only a few basic parameters that affect the correction. In this mode, the degree of correction increases with increasing fuel consumption. With an increase in a certain threshold value of the speed of rotation, the degree of correction may decrease (determines the user).

In the advanced mode, the user can make a detailed map of the correction of signals depending on the time of fuel injection and the crankshaft speed separately for lambda probes and DMRV.

To avoid errors in the electronic control unit (ECU) of the car, correction of signals from the oxygen sensors is performed after a certain time after the ignition is switched on (user determines).

The device can work with DMRV, having both an analog output and a pulse output.

The optimizer supports broadband and zirconia oxygen sensors (lambda probes). When working with broadband sensors, it is possible to accurately measure, maintain and control the lambda (fuel mixture composition) value.

Installation and adjustment of this system of fuel economy can be vyponena both independently and by specialists of SRT according to the instruction.

The "SuperAquaCar" system can be additionally equipped with other fuel saving devices that increase the result. The maximum effect is achieved by the joint use of "SuperAquaCar", "Fuel Activator" and "NanoVit Motor-Renovator".

Our "SAC" system is the most effective and safe of all similar systems, represented on the Ukrainian market.

At present, SAC is fully adapted for operation in winter and is available for engines up to 16 liters.

We guarantee a minimum 25% reduction in the consumption of gasoline, diesel 20%, propane-butane 15% when installing "SAK" on specialized service stations. Within 30 days from the date of sale, in the absence of the above effect, you can return to us the entire package in exchange for the cost of the kit, provided that the presentation is preserved. The cost of works is not included in the cost of the kit.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.