UPG-2

- START

- EKOTYUNING-KIT

- SuperAquaCar

- Pulse

- UPG-2

- Activator Magnetic

- Fuel Activator

- Water injection (ECOMACS)

- HBO

- NanoVit

- V-Tech box

- EcoTop

- AirWing

- Anticoron AKOR

- Roher

- Ecotuning Oil

- Efficiency plus

- FFI MPG Supplements

- Zero filters (K & N)

- Lambda probe emulator

- Diesel particulate filter emitter

- Emulator of lambda probe and MAF

- Usefulness

- A PHOTO

- BUY & CONTACTS

Nitrogen is the only "participant" in the combustion process in the engine that passes through the transit. For the combustion process, it is ballast. UPG-2 acts by high-voltage electric current on the air entering the engine, breaking up molecules (including nitrogen molecules) into atoms, providing improved combustion and nitrogen involvement in this process.

This gives an improvement in the combustion quality of the mixture. That in turn leads to an increase in engine power, saving gasoline, reducing emissions, prolonging the life of the oil and engine parts.

When the fuel-air mixture ignites in the internal combustion engine (DIC), the oxygen decomposition reaction takes place, due to the binding energy of its elementary particles and energy is released. Being a kind of ballast in the air, nitrogen does not take part in this combustion, because Energy released during combustion is not enough to split the nitrogen molecule (N2) into atoms and involve them in the combustion process. At the same time, if some action can destroy N2 molecules by atoms, they can be involved in the combustion process. This can really be achieved by using a high-voltage current or by creating a powerful electromagnetic field using a catalyst. At the same time, an increase in power to 20%

As a result of scientific research and various tests, a special device was designed to enhance the combustion reaction of the fuel mixture for internal combustion engines UPG-2. Device UPG allows you to save gasoline at a level of 15 - 25%.

UPG-2 - is a signal generator capable of applying high-voltage electric current to the air entering the engine. Under the influence of gasoline saving device UPG air molecules are split into atoms, which, in turn, contributes to the maximum complete and rapid combustion of the fuel-air mixture.

The device for saving petrololine UPG-2 can be used in engines running on gasoline of any brand, as well as gas and diesel fuel.

Using the device UPG allows to significantly increase engine power (by 10-20%), to reduce the level of emission of harmful substances into the atmosphere 3 times, to reduce fuel consumption by 15-25%, to switch to the use of gasoline with a lower octane number (for example, with A 95 at A92) and increase the life of the engine components. Installing UPG does not require structural changes in the engine compartment and engine reconfiguration.

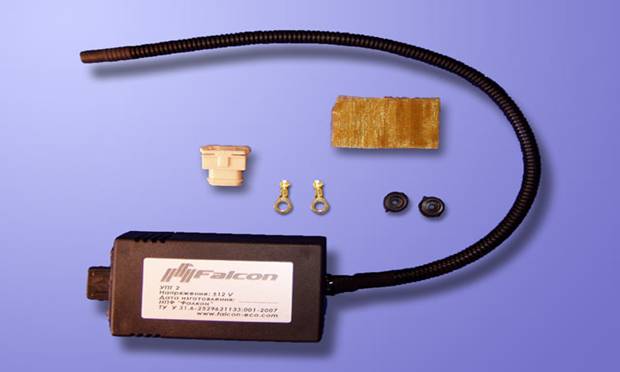

Kit and characteristics

The device UPG guarantees a reduction in fuel consumption and increased power of the car. All this is realized by increasing the completeness of combustion of gasoline in the combustion process.

In the illustrations below, the delivery set of the device for strengthening the combustion process of UPG , as well as its technical characteristics, is given.

Principle of operation

When the fuel / air mixture ignites in the internal combustion engine, the oxygen decomposition reaction in the air takes place. Nitrogen (the content in the air is 78%) does not take part in the combustion process, being essentially a ballast in the air. This is due to the fact that the energy released is not enough to split the nitrogen molecule into atoms, and to engage it in the combustion process.

Nitrogen molecules in combustion are possible only if they are first broken down into atoms or more fine particles. Such a combustion process is called nitrogen combustion, with this burning process water (H2O), partially oxygen (O2), carbon (C), and NOX, CO and other substances (but in a smaller amount) will be released, and this is more efficient from the standpoint of Ecology and energy costs. Such a result is possible only if a powerful electromagnetic field with a catalyst is used or when a high-voltage current is used.

For this purpose the device "UPG-2" was developed, for use in all existing internal combustion engines.

Outwardly it is a signal generator that, when exposed to a high voltage current by air, breaks nitrogen and oxygen molecules into atoms, while providing an increase in the chemical activity of the treated air, and uses nitrogen in the combustion process. Also, it guarantees complete combustion of the extremely lean air-fuel mixture.

"UPG-2" is used on all types of internal combustion engines - gasoline, diesel, and also using gas. This allows: 1) to reduce fuel consumption by 15-25% 2) to increase the engine power by 10-20% 3) to reduce the CO emission by 3 times 4) the possibility of switching to gasoline with a lower octane number 5) to reduce engine wear, Service catalysts, diesel injectors, lambda probes and spark plugs.

With the use of "UPG-2" the car will become more elastic and priemisty. The engine will respond to pressing the accelerator of the gas faster and softer, which will evenly accelerate under any conditions. And also there is a compensation of power when working climate control or air conditioning, especially this is true for small cars.

The device itself is installed in the engine compartment without structural changes and is reliable, compact and safe. Increases power, saves fuel.

Technical characteristics UPG-2

Application area

The field of application of the electronic amplifier of the combustion process of fuel (UPG-2) is quite wide. Since UGG-2 can be used in any internal combustion engine, it does not matter what type of fuel is used, whether it is gasoline, gas or diesel fuel, this device can be called universal. Wherever the combustion process occurs, the same problem arises: the combustion efficiency of the fuel mixture. The UPG-2 device optimizes the combustion process by applying a high-voltage current to the air entering the engine, destroying oxygen and nitrogen molecules to atoms and drawing the latter into the combustion process.

As a result of this intervention, a complete combustion of the fuel-air mixture takes place, resulting in a significant (up to 20%) increase in engine power, significant fuel economy due to increased efficiency and, as a result, operation at lower revs and an increase in the working life of engine parts.

In addition, the environmental performance of the engine is increasing due to a reduction in the emission of harmful substances into the atmosphere. This is due to the change in the composition of the exhaust gases due to the complete combustion of the fuel mixture. What can not but please ecologists and people who care about the cleanliness of the environment is not indifferent.

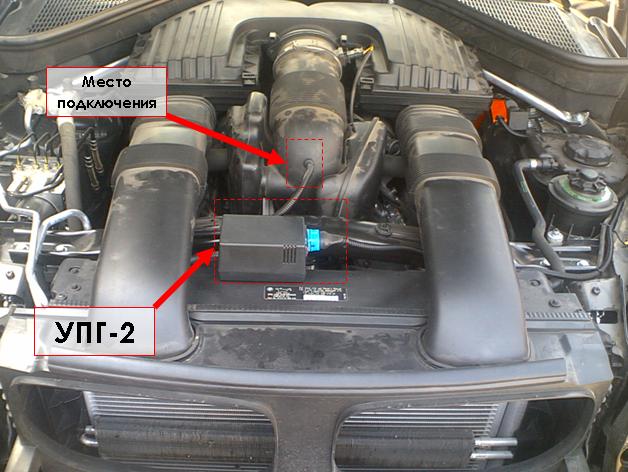

The order of installation of "UPG-2"

The amplifier should only be installed on a technically sound vehicle!

- Before mounting, select the location of the signal conditioner and activator.

- When mounting the amplifier, the activator and the activator connector must be installed only in non-metallic nozzles, and the distance from the car's conductive elements must be at least 5 cm.

- The activator can be installed:

- - in the air filter housing (after the filter);

- - in the duct connection after the filter;

- - in the duct connection before the filter.

- When installing the activator in the nozzles, the activator plug must be at the beginning of the airflow. When installed in a casing, the distance to the flowmeter must be at least 15 cm from any edge of the activator.

- The signal conditioner is fixed at a distance of no more than 30 cm from the activator connector in any accessible place in the engine compartment of the vehicle. For fixing, a double-sided adhesive tape on a polypropylene base can be used.

- Connecting the signal conditioning to the power supply is done using the connector provided with the mounting kit. Plus 12 volts is fed to the second (middle) pin of the connector, minus (the case) is fed to the third pin of the connector, it is indicated by the number 3 on the connector.

To protect from moisture, the connector must be greased with graphite grease before connecting with the mating part. When using 24 volt electronics, the device is connected to the battery.

Manufacturer's warranty

UPG-2 - a special device designed to enhance the combustion process of the fuel mixture in existing internal combustion engines. The principle of the device is based on the splitting of air molecules into atoms under the action of a high-voltage current. The device can be used on engines working on any type of fuel: gasoline, gas, diesel fuel. Depending on the technical condition of the engine, the effect of the amplifier may be noticeable at various times from the date of commissioning, but not later than 12 days from the date of installation.

The manufacturer of the device UPG-2 is responsible for compliance with technical requirements in accordance with TU 31.6-2529621133-001: 2007 and is fully responsible for the reliable and faultless operation of this device during the entire warranty period of operation, provided that the storage and installation conditions are observed. The warranty period of operation of the UPG-2 device is 2 years from the date of commissioning, but does not exceed 30 months from the date of purchase of the device by the consumer. In the event of a malfunction in the amplifier during the warranty period with the buyer's strict observance of the operating rules, the manufacturer must replace the device for free.

Tests

When introducing the "UPG-2" device to the market, consumers have natural questions and concerns related to it. The main issues remain the safety of the application of this device on the car, will it not affect the operation of the engine and whether it will lead to a malfunctioning condition, and also, does it increase the octane number of gasoline (which is also harmful to the car)?

The given fears are caused by experience of consumers after introduction on the market of some additives and additives for fuel, which adversely affected the work of engines. Therefore, many decided that it is better to overpay than to save.

Therefore, to confirm the reliability of this device, experiments were conducted with his participation. The basis was taken by four main parameters: the octane number, the mass fraction of sulfur, the fractional composition, the concentration of actual resins in mg per 100 cm of cubic gasoline.

The purpose of the tests was the desire to prove that when applying "UPG-2" on the car, the above parameters do not exceed the permissible values of GOST. For the experiment, A-92 gasoline was taken and the corresponding measurements were made when the engine was running. The results obtained were compared with the results of a normal engine using the same gasoline.

After comparing the results it was found out that: the octane number of gasoline did not increase. The concentration of actual resins and sulfur in the fuel does not increase, the temperature of distillation of the fractions of gasoline does not increase. Well, it is important that the combustible gasoline by all standards does not contradict GOST, which proves the safety of the application of "UPG-2" in cars.

Comments

Commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.