| Start of section

Production, amateur Radio amateurs Aircraft model, rocket-model Useful, entertaining |

Stealth Master

Electronics Physics Technologies Inventions |

Secrets of the cosmos

Secrets of the Earth Secrets of the Ocean Tricks Map of section |

|

| Use of the site materials is allowed subject to the link (for websites - hyperlinks) | |||

TECHNOLOGY OF MANUFACTURE Plus SELECTING STABILIZERS

FOR MODELS OF ROCKET

![]()

Aminov Oleg Maksimovich

Glossary of terms |

|

A LITTLE THEORY

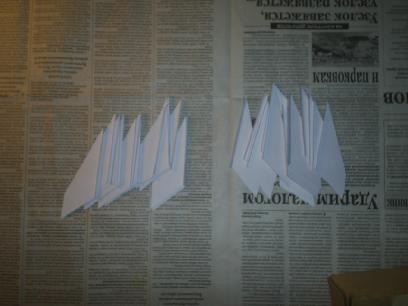

The stability of the missile's flight in the atmosphere is largely provided by stabilizers, which are installed at the very end of the rocket, and they should be installed as if near to the outskirts - this provides the most stability of the missile in flight. Stabilizers can be in full different shapes. The figure shows the stabilizers, which provide the greatest stability.

|

|

|

|

Nevertheless, the required dimensions, as well as the type of stabilizers, largely depend on the characteristics of the rocket itself, from such as: aerodynamics, flight speed, engine room, even the temperature of the engine compartment, It is almost in the same place in which the stabilizers are fixed.

The aerodynamics of the rocket determines the shape of the stabilizers, because For different lengths of the rocket body, their range may be different. For example, if the hull is extremely small, but full, then the swing of the stabilizers should be made large, carried for the length of the rocket, because you know that the longer the body type is, the thinner it is, the more straightforward its flight path is also stable.

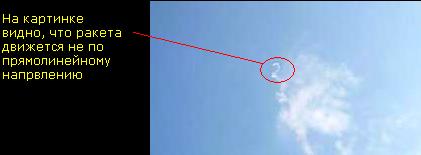

A very impressive role is played by the speed of the flight of the rocket, and here it must be a little cautious. I, during the tests of missile models, were often ripped off by stabilizers, and for a long time we could not understand the reason. But still the first reason we found is the angle of rotation of the stabilizers relative to the axis of the missile's body. If the speed of the rocket is enormous, only the range of the stabilizers is large, and they are sufficiently shifted relative to the axis of the shell, and besides, they are made of elastic material, they can simply be demolished, The slightest reciprocal light stream, at this speed, has an impressive pressure, can also cause deformation of the stabilizer fixation, because of which it can come off, but if the mount is strong, then the rocket will simply sharply change its trajectory and also fly in the wrong course, in which you Conceived.

The figures depict the location of the stabilizers relative to the axis of the missile hull:

|

|

As you can see in the figure, on the right, the stabilizers are located with a displacement along the axis of the hull, and this will also have a very significant effect on the flight path of the rocket. The pressure of the gas stream acting on the stabilizers will become enormous, too, if they are made of insufficiently strong material or are not attached securely, they can be demolished. Even if they do not come off in any way, the trajectory of a rocket's flight will change greatly, only this can lead to very unpleasant situations or even lead to tragedy. As we have already noted, this should be given considerable attention.

Let's now discuss the location of the engine, why do we need to take this characteristic into account? In addition to the fact that I often tore off stabilizers, they also often burned. But the reason for this we found quite quickly, too, was the occupation in the engine room. Look at the image below and you will understand everything.

If the angle of the exit section of the nozzle is extremely large, then the engine should be slightly pushed out of the housing, just estimate to the eye, at what angle the gas flow will diverge and also stick the engine out for a certain length.

Let's now deal with the effect of engine temperature on stabilizer mounts. In addition to the above reasons, for which I often flew stabilizers, this occasion also played an important role. As we saw at that time, when using engines with a paper casing, there was no special problem, but when I used my rechargeable engine with a thin-walled metal casing, as if verbally within a few seconds of the flight, the trajectory of the rocket changed greatly.

On the smoke strip it was perfectly visible that she was joking in different directions. Later such launches, we often did not find our missiles in any way. Ran them without a parachute, they were just test pieces. But still, by the method of long searches, I managed to find one.

|

|

As you can see, there was only one stabilizer left on the rocket, only the back part of the source casing burned out. During the flight, as a result of the action of high temperature, the stabilizer mounts melted, as a result of this, the stabilizers were unstable in their place, also because of the huge aerodynamic drag, they were simply demolished.

As you have noticed, there are many reasons for stalling the stabilizers of the non-rectilinear flight trajectory of the rocket. Let's discuss now, as if we should distribute the weight load in the missile's hull.

Surely you know about such concepts, as if the center of gravity is also the center of pressure. The closer to the nose elements the weight load is shifted, the more straightforward the trajectory of the rocket flight is, the more stable it is. I want to note that the center of gravity is forced to be virtually always above the center of pressure.

The more the authority of the engine, the more the nose elements of the rocket are forced to have authority, so that the center of pressure as if it could be moved further relative to the center of gravity. For example, I, as a fairing, used a metal can from the siphon. He helped balance the weight load on both ends of the rocket. Here is the general view of my rocket:

This simple rocket, without a parachute, is designed to test small engines. In its system enters only the fairing, the body, the guide rings, the stabilizers are also the engine itself. You can learn more about this rocket in the corresponding section, just now let's go back to the stabilizers.

TECHNOLOGY OF MANUFACTURING STABILIZERS

Here we will not consider all forms of stabilizer sizes in any way, we will only talk about the general principle of their manufacture. We will operate those stabilizers that you see on the photo of my rocket.

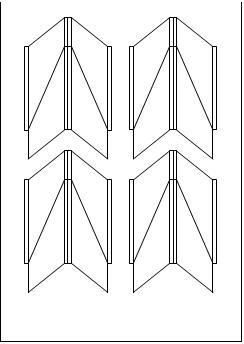

So, you will need the following things: a dense drawing paper, a printer or an exact ruler with a pencil. Make such a drawing

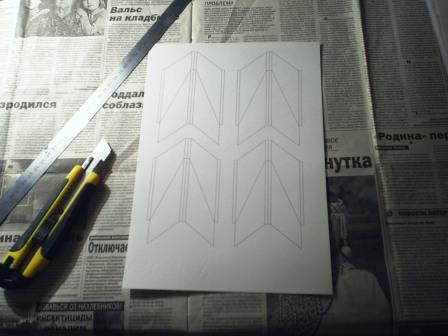

Or download it in doc format, only then print on thick A4 size drawing paper. Then you need to cut out the shapes:

Cut them out can also be painful, but we will share an experiment with you, as if to do it more optimally.

Before venturing to cut, I want to warn you that the folding districts of the fastening should not be cut in any way, just cut, so that they can easily be bent along the line. In the figure they are marked in blue.

So, lightly pressing on the clerical knife, as if you can cut the main lines more accurately. At the same time, by no means do not cut the sheet in any way. Areas that are easy to cut are marked with a red color:

|

|

Here, as if I did it

Then make the following cuts, while trying not to please the features of the fold. In principle, you can cut a sheet into 2 parts, on the last lines, well, that's already your taste.

And, in the end, the final moment in this tedious occupation. The lines that are marked in red must be cut.

|

|

Lines that do not cut well need no exact ruler. Just carefully again once again swipe along these lines, and the end of the knife will begin to move accurately, along the already cut, circle. As a result, you will get thin beautiful figures of stabilizers.

The wisest route behind, now, gluing together these figures, we will get the long-awaited stabilizers. At this stage, it is very proud to choose an unmistakable glue. Previously, we used liquid glass, because It betrayed to them a good strength also heat resistance, although it is not absolutely necessary to act as heat-resistant ones. But in the long run, we switched to epoxy resin, because It has a number of impressive advantages in comparison with liquid glass: water resistance, low weight, preservation of the unchanged volume during solidification, elasticity of the composition, comparatively long time of solidification, it is as if the stabilizer can be calibrated as closely as possible in its shape. Also, the epoxy does not expand in any way, and does not compress the mold in any way, as if it is a liquid glass, so that the accuracy of the stabilizer will directly depend on how it is fixed at the initial moment.

Now let's talk about epoxy. As we have noticed, it is sold in many hardware stores, but it happens in full different versions. Here you need to take the most dense, because In the liquid contains a lot of different plasticizers.

So, we made figures, now we will glue them together. First, distribute the workpieces along similar sides and prepare the necessary portion of epoxy resin.

Then we apply a layer of epoxy resin to the blanks. The layer does not have to be extremely thick or extremely thin.

Now we only need to glue the finished elements and align them along the lines of the fold so that the stabilizers are even.

As a stand, you can use the ruler.

Making good stabilizers is very delicate and requires some skill.

Later, as if we had blinded the blanks between them, they must be left for a while, so that the epoxy becomes more viscous. This is to ensure that at what time we will fix them in no way did the displacement between the layers occur. Just look not to go too far in time, only the epoxy will harden and you will already vryatli able to align them.

So, after a while, at what time the epoxy thickened, we again start to smooth the stabilizers along the bend line, at this point you need to be clearly precise, so that the devil in the devil. Particular attention should be paid to the placement of the fold, because This room gives the answer for the accuracy of the location of the entire stabilizer relative to the axis of the missile's body.

Later all these processes come the final stage - fixing stabilizers. It looks like, no less significant stage, because depending on how you fix them, they will also hang their evenness. To fix stabilizers, we will use books.

When you fix them in the book, then carefully take it and put it on a flat surface.

Glasses for fixing photos that were used years 50-60 back, but not all people have such glasses, will be just as good. Before using the textbook, it is necessary to cover the pages with a layer of scotch, those that will be in direct contact with the stabilizers. On the stabilizers there is still epoxy resin, they can also stick.

After 24 hours, the resin will harden.

Now, if you want, for beauty they can be covered with a layer of colored scotch. Of course, it's also common, it's even necessary, because Adhesive tape will give them an impressive streamline and waterproofing.

The adhesive tape should be applied evenly. It is advisable to carry out all work on a wooden board, because you will have to cut off the scotch, agree that it is a pity to use the table for such purposes.

First, we apply a layer of adhesive tape exactly on the surface of the stabilizer.

Now, for the selected adhesion of the adhesive tape to the surface of the stabilizer, we iron it with a matchbox.

Then it will be necessary to trim the remains of the scotch carefully.

Plus, we perform the same procedure with the other side of the stabilizer.

In the end, stabilizers are also ready to use them today.

These stabilizers have sufficient flexibility and elasticity, but also have good hardness. Such mechanical characteristics help them to easily overcome counter-flowing air currents. Their lightness, streamlining is also subtle, they have a friendly effect on the flight characteristics of the rocket. In addition, they can be produced in impressive quantities, and this is even very profitable, for economic reasons.

![]()

FROM THE AUTHOR

In this article, we tried to clearly describe my production of stabilizers and I hope that I did it. I believe that these stabilizers are very alternative for missile models. Just want to note that for the manufacture of impressive stabilizers for impressive missiles (from 2m ), this technology does not quite fit, because The material for their manufacture must be thick enough, in this case it is better to cut them out of a dural-aluminum or plywood sheet. In my next article, I'll try to describe, as if to do it optimally. But we still think that you yourself also know perfectly well that this is done, only if you can not think of it, then this technique can be found on numerous web pages of rocket-modelers.

I want good luck!

print version

Author: Aminov Oleg Maksimovich

PS The material is protected.

Date of publication 22.02.2005гг

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.