| Start of section

Production, amateur Radio amateurs Aircraft model, rocket-model Useful, entertaining |

Stealth Master

Electronics Physics Technologies Inventions |

Secrets of the cosmos

Secrets of the Earth Secrets of the Ocean Tricks Map of section |

|

| Use of the site materials is allowed subject to the link (for websites - hyperlinks) | |||

Navigation: => |

Home / Inventions / Entertaining inventions / |

|

NEW GENERATION OF REFRIGERATING EQUIPMENT

METHOD OF MAGNETIC COOLING

![]()

E.N. Tishina

See also: |

The technology of magnetic cooling is based on the ability of any magnetic material to change its temperature and entropy under the influence of a magnetic field, as occurs when compressing or expanding gas or steam in traditional refrigerators. Such a change in the temperature or entropy of a magnetic material with a change in the strength of the magnetic field in which it is located is called the magnetocaloric effect (MCE) . The change in the temperature of the magnetic material occurs as a result of the redistribution of the internal energy of the magnetic substance between the system of magnetic moments of its atoms and the crystal lattice. The maximum value of MCE is obtained in magnetically ordered materials, such as ferromagnets, antiferromagnets, etc., at temperatures of magnetic phase transitions (magnetic ordering temperatures - Curie, Neel, etc.). The main advantage of the apparatus for magnetic cooling is associated with a high density of the material - a solid body - in comparison with the density of steam or gas. The change in entropy per unit volume in solid magnetic materials is 7 times higher than in a gas. This allows you to make much more compact refrigerators, using a magnetic material as a working medium. The magnetic working medium itself serves as an analog of refrigerants used in traditional combined-cycle refrigerating plants, and the demagnetization-magnetization process is analogous to compression-expansion cycles.

The efficiency of the refrigerator is mainly determined by the amount of irreversible work done during the cycle - for effective devices it should be as low as possible. In the gas refrigerator there are devices that produce a significant amount of irreversible work - a regenerator, a compressor and heat exchangers. Much of the irreversible work is done in heat exchangers - it is directly proportional to the adiabatic change in the temperature of the working fluid, which is much larger in the gas than in the magnetic material. For this reason, the most efficient heat removal occurs in the magnetic refrigeration cycle, especially in the regenerative one. The special design of the heat exchanger and the use of a regenerator with a large surface area make it possible to achieve a small fraction of irreversible work during magnetic cooling. According to theoretical estimates, the efficiency of the magnetic regenerative refrigeration cycle in the temperature range from 4.5 to 300 K can be from 38 to 60% of the efficiency of the Carnot cycle (about 52% in the temperature range from 20 to 150 K , and about 85% in the range from 150 to 300 K ). In this case, at all stages of the cycle the heat transfer conditions will be the most perfect of the known ones. In addition, magnetic refrigerators include a small number of moving parts and operate at low frequencies, which minimizes wear on the refrigerator and increases the operating time.

Basic principles of magnetic cooling

The MCE was discovered relatively long ago (in 1881 ) by E. Warburg . Warburg observed how, under the action of a magnetic field, an iron sample was heated or cooled. The scientist concluded that the change in the temperature of the sample is a consequence of the change in the internal energy of a substance with a magnetic structure under the action of the field. However, before practical use of this phenomenon was still far away. Langevin (1905) was the first to demonstrate that a change in the magnetization of a paramagnet leads to a reversible change in the temperature of the sample.

Actually, magnetic cooling was proposed almost 50 years after the discovery of the MCE independently by two American scientists Peter Debye (1926) and William Giauque (1927) as a way of reaching temperatures below the boiling point of liquid helium. Jiok and Mac Dugall were the first to demonstrate the simplest experiment on magnetic cooling in 1933 . (A little later, de Haas (1933) and Kurti (1934) did this . ) In the course of this experiment, it was possible to reach a temperature of 0.25 K , and as a heat sink substance, liquid helium was pumped at a temperature of 1.5 K. A tablet with a magnetic salt Was in a state of thermal equilibrium with the heat sink material, while a strong magnetic field existed in the solenoid.When the solenoid was discharged, the magnetic tablet was thermally isolated and its temperature decreased.This technique, called cooling by adiabatic demagnetization, is a standard laboratory technique used to obtain ultra-low temperatures. However, the capacity of such a refrigerator and its operating temperature range are too small for industrial applications.

More complex methods, including thermal regeneration and cyclic changes in the magnetic field, were proposed in the 60s of the last century. J. Brown from NASA in 1976 demonstrated a regenerative magnetic refrigerator operating near room temperature with an operating temperature range of 50 K. The power of the refrigerator and its efficiency were still low in this case, since the temperature gradient needed to be maintained by mixing the heat sink liquid, and the time required for charging and discharging the magnet was too great. Small low-power refrigerators were built in the 1980s and 1990s in several research centers: Los Alamos National Lab, the Navy Lab at Annapolis, the Oak Ridge National Lab, Astronautics (all USA), and Toshiba (Japan) .

At present, work on small magnetic refrigerators for space applications, working on the principle of adiabatic demagnetization, is funded by several NASA research centers. Studies of the possibilities of magnetic refrigerators for commercial applications are being conducted by the Astronautics Corporation of America (USA, Wisconsin) and the University of Victoria (Canada) . A study of materials for working bodies of magnetic refrigerators from an applied point of view is currently being intensively studied by the Ames Laboratory (Ames, Iowa), the University of Three Rivers in Quebec (Canada), NIST (Gathersburg, MD) and the company "Advanced Magnetic Technologies and Consultations" ( AMT & C) .

In 1997 , the Astronautics Corporation of America demonstrated a relatively powerful ( 600 Watt ) magnetic refrigerator operating near room temperature. The efficiency of this refrigerator was already comparable with the efficiency of conventional Freon refrigerators. Using an active magnetic regenerator (this device combines the functions of a thermal regenerator and a working fluid), this refrigerator operated for more than 1500 hours , providing a working temperature range of 10 K near room temperature, a power of 600 watts , an efficiency of about 35% with respect to the cycle Carnot with a change in the magnetic field of 5 Tesla . In the described device, a superconducting solenoid was used, and the rare earth metal of gadolinium ( Gd ) was used as the working medium. Pure gadolinium was used in this capacity not only by Astronautics , but also by NASA, Navy and other laboratories, which is due to its magnetic properties, namely, a suitable Curie temperature (about 20 ° C ) and a rather significant magnetocaloric effect.

The magnitude of the MCE , and therefore the efficiency of the cooling process in a magnetic refrigerator, is determined by the properties of the magnetic working bodies. In 1997, Ames Laboratory reported the discovery in the compounds Gd5 (SihGe1-x) 4 giant magnetocaloric effect. The temperature of magnetic ordering of these materials can vary over a wide range from 20 K to room temperature due to a change in the ratio of silicon ( Si ) and germanium ( Ge ). The most promising for use as working bodies are currently gadolinium metal, a number of intermetallic compounds based on rare-earth elements, a system of compounds of silicide germanides Gd5 (Ge-Si) 4 , a and La (Fe-Si) 13 . The use of these materials allows the working temperature range of the refrigerator to be extended and its economic indicators significantly improved.

Let us note, however, that the pioneering work on the search for effective alloys for working bodies of magnetic refrigerators was carried out several years earlier at the Physics Department of Moscow University. The most complete results of these studies are set forth in the doctoral dissertation of the leading research assistant of the Physics Department of the Moscow State University, A. M. Tishina, 1994 . In the course of this work, numerous possible combinations of rare-earth and magnetic metals and other materials have been analyzed from the point of view of searching for optimal alloys for the realization of magnetic cooling in different temperature ranges. It was found, in particular, that among materials with high magnetocaloric properties, the compound Fe49Rh51 (iron-rhodium alloy) has the largest specific (ie, per unit magnetic field) magnetocaloric effect. The specific FEC for this compound is several times greater than in the compounds of silicide-germanides. This alloy can not be used in practice because of its high cost, and significant hysteresis effects in it, however, it can serve as a kind of standard with which to compare the magnetocaloric properties of the materials being studied.

Finally, in January of this year, Science News (v.161, n.1, p.4, 2002) reported the creation in the US of the world's first household (that is applicable not only in scientific but also for domestic purposes) Refrigerator. A working model of such a refrigerator was produced jointly by Astronautics Corporation of America and Ames Laboratory and was first demonstrated at the G8 conference in Detroit in May 2002 . The working prototype of the proposed household magnetic refrigerator operates in the room temperature range and uses a permanent magnet as the field source. Speaking about this revolutionary achievement, Professor Karl Schneider from Ames Laboratory noted: "We are witnessing a historic event in the development of technology.In the previously shown magnetic refrigeration devices, large superconducting magnets were used, but in this new magnetic refrigerator the permanent magnet that does not require cooling was first used" .

The device was highly appreciated by experts and the US Energy Secretary. Estimates show that the use of magnetic refrigerators will reduce the total energy consumption in the US by 5% . It is planned that magnetic cooling can be used in a wide range of human activities - in particular, hydrogen liquefiers, cooling devices for high-speed computers and SQUID devices, air conditioners for residential and industrial buildings, cooling systems for vehicles, in household and industrial refrigerators etc. It should be noted that the work on magnetic refrigerators has been funded by the US Department of Energy for 20 years already .

Refrigerator construction

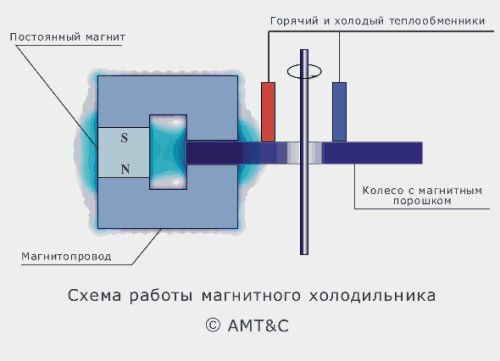

In the prototype of the magnetic refrigerator, a rotating wheel arrangement is used. It consists of a wheel containing segments with gadolinium powder, as well as a powerful permanent magnet.

The design is designed in such a way that the wheel is scrolled through the working gap of the magnet, in which the magnetic field is concentrated. When a segment with gadolinium enters the magnetic field in gadolinium, a magnetocaloric effect arises - it heats up. This heat is removed by a water-cooled heat exchanger. When gadolinium leaves the magnetic field, a magnetocaloric effect of the opposite sign arises and the material is further cooled, cooling the heat exchanger with the second water flow circulating therein. This flow is actually used to cool the refrigerating compartment of the magnetic refrigerator. This device is compact and operates virtually noiselessly and without vibrations, which distinguishes it from the currently used refrigerators with the steam-gas cycle.

"The permanent magnet and gadolinium working fluid do not require energy," says Professor Karl Schneider of the Ames Laboratory, "the energy is needed to rotate the wheel and ensure the operation of the water pumps."

For the first time this technology was tested in September 2001 . Currently, work is underway to further expand its capabilities: the technological process of commercial production of pure gadolinium and the necessary compounds thereof is being improved, which will allow achieving a larger value of FEM at lower costs. At the same time, the Ames Laboratory staff constructed a permanent magnet capable of creating a strong magnetic field. The new magnet creates a field twice as large as the magnet in the previous design of the magnetic refrigerator ( 2001 ), which is very important, because The magnitude of the magnetic field determines such parameters of the refrigerator as efficiency and output power. Applications for a patent are filed for the process of obtaining a compound for the working substance Gd5 (Si2Ge2) and for the construction of a permanent magnet.

Advantages, disadvantages and applications

All magnetic refrigerators can be divided into two classes according to the type of magnets used: systems using superconducting magnets and systems on permanent magnets. The first of them have a wide range of operating temperatures and a relatively high output power. They can be used, for example, in air conditioning systems in large rooms and in food storage equipment. The permanent magnet cooling systems have a relatively limited temperature range (no more than 30 ° C per cycle) and, in principle, can be used in devices with an average power (up to 100 watts ) - such as an automobile refrigerator and a portable picnic refrigerator . But they both have a number of advantages over traditional combined-cycle refrigerating systems:

Low environmental hazard: The working body is solid and can be easily isolated from the environment. The lanthanide metals used as working bodies are low in toxicity, and can be reused after recycling the device. The heat dissipating medium must have only a low viscosity and sufficient thermal conductivity, which corresponds well to the properties of water, helium, or air. The latter are well compatible with the environment.

High efficiency. Magnetocaloric heating and cooling are practically reversible thermodynamic processes, in contrast to the process of vapor compression in the working cycle of a combined-cycle refrigerator. Theoretical calculations and experimental studies show that magnetic cooling units are characterized by higher efficiency. And economy. In particular, in the field of room temperatures, magnetic refrigerators are potentially 20-30% more effective than those operating in the gas-vapor cycle. The technology of magnetic cooling in the future can be very effective, which will significantly reduce the cost of such installations.

Long service life. The technology involves the use of a small number of moving parts and low operating frequencies in cooling devices, which significantly reduces their wear and tear.

Flexibility of technology. It is possible to use various designs of magnetic refrigerators, depending on the purpose.

Useful properties of freezing. Magnetic technology allows cooling and freezing of various substances (water, air, chemicals) with minor changes for each case. In contrast, an efficient combined-cycle cooling cycle requires many separate stages or a mixture of different working coolants for the same procedure.

Rapid progress in the development of superconductivity and the improvement of the magnetic properties of permanent magnets. Currently, a number of well-known commercial companies are successfully engaged in improving the properties of NdFeB magnets (the most efficient permanent magnets) and are working on their designs. Along with the known progress in the field of superconductivity, this allows us to hope for an improvement in the quality of magnetic refrigerators and their simultaneous cheaper.

Disadvantages of magnetic cooling

- The need to screen a magnetic source.

- The relatively high current price of magnetic field sources.

- Limited temperature range in one cooling cycle in permanent magnet systems. (Not more than 30 ° C).

Will Russia independently develop super-promising technology?

In our country until now, the problem of magnetic cooling exists only at the level of scientific laboratories, although it was the Russian scientists who in the early 1990s carried out the first work on the theory and practice of using FEM to create magnetic refrigerators. In co-authorship with the employees of the company "Perspective Magnetic Technologies and Consulting" and the Physics Department of Moscow State University for many years, the creators of the working prototype of a magnetic refrigerator, which was discussed above, have been working. Unfortunately, in Russia such developments are conducted at an insufficient level due to the lack of necessary funds. There is no doubt that with the appropriate financial support of state or commercial structures, the development of technology and the production of magnetic refrigerators in Russia are certainly possible. In our opinion, it is necessary in the very near future to involve all interested parties in the work in this direction.

print version

Author: E. N. Tishina

PS The material is protected.

Date of publication 08.12.2004гг

You can also support shram.kiev.ua, press:

It will not be superfluous for your friends to learn this information, share their article with them!

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.