Chernobyl: Part. PREVENTION OF ACCIDENT DEVELOPMENT AND REDUCTION OF ITS CONSEQUENCES.

Information on the Chernobyl accident and its consequences prepared for the IAEA Report No. 1 (INSAG-1)

C O D E R A N E E

Flash drive

0. Introduction

1. Description of the Chernobyl NPP with RBMK-1000 reactors.

2. Chronology of the development of the accident.

3. Analysis of the process of development of the accident on a mathematical model.

4. Causes of the accident.

5. Preventing the development of an accident and reducing its consequences.

6. Control over radioactive contamination of the environment and public health.

7. Recommendations for improving the safety of nuclear power.

5. PREVENTION OF ACCIDENT DEVELOPMENT AND REDUCTION OF ITS CONSEQUENCES

5.1. Fighting fire at nuclear power plants

5.2. Assessment of the state of fuel after an accident

5.3. Limiting the consequences of an accident in the reactor core

5.4. Activities on the first - third blocks

5.5. Monitoring and diagnostics of the status of the emergency block

5.6. Decontamination of the nuclear power plant site

5.7. Long-term conservation of the fourth block

5.8. Decontamination of the 30-kilometer zone and the resumption of economic activities

5.1. Fighting fire at nuclear power plants

The first task after the accident at the reactor was to fight the fire that had started.

As a result of explosions in the reactor and the release of the fragments of its core heated to high temperatures,> 30 fires occurred on the roofs of some rooms in the reactor compartment, deaerator stack and the engine room. Due to damage to individual oil pipelines, short circuits in electrical cables and intense heat radiation from the reactor, fires in the engine room over TG No. 7, in the reactor hall and adjoining partially destroyed rooms were formed.

At one hour and 30 minutes, duty units of the fire department for the protection of nuclear power plants from Pripyat and Chernobyl left for the scene of the accident.

In view of the direct threat of spreading the fire over the covering of the engine room to the neighboring, third unit and its rapid reinforcement, the priority measures were aimed at eliminating the fire precisely in this sector. It was also organized to extinguish the emerging foci of combustion inside the premises with the use of fire extinguishers and stationary internal fire hydrants. By 2 hours 10 minutes on the roof of the computer room and 2 hours 30 minutes on the roof of the reactor compartment the main fire centers were suppressed. By 5 o'clock in the morning the fire was liquidated.

5.2. Assessment of the state of fuel after an accident

The accident resulted in partial destruction of the reactor core and complete destruction of the cooling system.

To solve the problem of preventing the development of the accident and limiting its consequences in the first hours after the accident, considerable efforts were made to assess the state of the fuel and its possible change over time.

A study of the dynamics of the expiration of the PD from the reactor in the first days after the accident showed that the temperature change of the fuel over time was nonmonotonic. It can be assumed that in the temperature regime of fuel there were several stages. At the time of the explosion, fuel was heated up. Estimation of the temperature by the relative leakage (the fraction of the isotope that expired from the fuel from its total content in the fuel at the point in time) of the iodine radionuclides showed that the effective temperature of the fuel remaining in the reactor building was 1600-1800 ° K after the explosion. Over the next few tens of minutes, the fuel temperature decreased as a result of heat release to the graphite masonry and reactor structures. This accordingly led to a reduction in the leakage of volatile PD from fuel.

At the same time, it was taken into account that the PD emission values from the reactor shaft were determined during this period mainly by the graphite burning processes and the associated migration processes of the fine-dispersed fuel and PD, embedded in the graphite as a result of the emergency explosion and the reactor. Then the temperature of the fuel began to rise due to the residual heat release. As a result, the leakage from the fuel of volatile radionuclides (inert gases, iodine, tellurium, cesium) increased. With a further increase in the temperature of the fuel, a leak of other so-called non-volatile radionuclides appeared. By 4 - 5 May, the effective temperature of the fuel remaining in the reactor unit stabilized, and then began to decline.

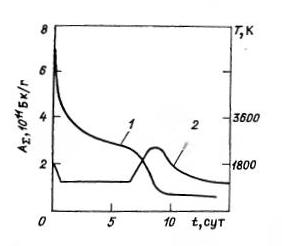

In Fig. 4 presents the results of the computational studies of the fuel condition: the results characterizing the residual radionuclide content in the fuel, as well as the temperature change of the fuel, taking into account the leakage from it of the AP, depending on the time elapsed after the accident.

Calculations have shown that the maximum temperature of the fuel can not reach its melting temperature, and the PD come to the surface of the fuel in batches, which can only lead to local overheating at the fuel-environment interface.

PDs that leave the fuel, in accordance with their values of the condensation and deposition temperature, fall on the structural and other materials surrounding the reactor in the reactor block. In this case, the radionuclides of krypton, xenon go almost completely outside the reactor unit, volatile PD (iodine, cesium) - in part, the others remain almost completely within the reactor building. Thus, the energy of the PD is scattered in the entire volume of the reactor block. As a result, the melting of the surrounding fuel medium and the movement of the fuel become unlikely.

Fig. 4. Change in activity (1) and fuel temperature (2) over time.

5.3.

Limiting the consequences of an accident in the reactor core

The potential possibility of concentrating part of the molten fuel and creating the conditions for the formation of a critical mass and the emergence of a spontaneous chain reaction required measures to be taken against this danger. In addition, the destroyed reactor was a source of emissions of a significant amount of radioactivity into the environment.

It was decided: to localize the center of the accident by throwing the reactor shaft heat sink and filtering materials.

A group of specialists on military helicopters began throwing the emergency reactor with boron compounds, dolomite, sand, clay, lead. From April 27 to May 10, only ~ 500 tons of materials were dropped, most of them from April 28 to May 2 inclusive. As a result of these actions, the reactor shaft was covered with a layer of loose mass, which intensively adsorbed aerosol particles. By May 6, the release of radioactivity ceased to be a significant factor, falling to several hundred, and by the end of the month - tens of curies per day.

At the same time, the problem of reducing fuel heating was solved. To reduce the temperature and reduce the oxygen concentration, nitrogen from the compressor station was fed into the space beneath the reactor shaft. By May 6, the temperature rise in the reactor shaft had ceased and its decline began due to the formation of a stable convective flow of air through the active zone into the free atmosphere.

As a reinsurance from the very unlikely (but possible in the first days after the accident) destruction of the lower tier of building structures, it was decided to urgently create an artificial heatsink horizon in the form of a flat heat exchanger on a concrete slab under the foundation of the building. By the end of June, the planned work was completed.

Experience has shown that the decisions taken were correct.

Since the end of May, the situation has largely stabilized. The destroyed parts of the reactor building were in stable positions. The removal of radioactivity from the block to the atmosphere was mainly due to the carryover of aerosols by wind. The temperature regime in the reactor shaft is stable. The maximum temperature values of the various sections were several hundred degrees Celsius with a stable tendency to decrease at a rate of ~ 0.5 ° C per day. The lower plate of the reactor shaft is preserved, and the fuel in the main (~ 96%) is localized in the reactor shaft and in the rooms of steam-water and bottom water lines.

5.4.

Activities on the first - third blocks

After the accident on the fourth block, the following activities were carried out at the first and third blocks:

- the first and second blocks were stopped at 1 h 13 min and 2 h 13 min on 27 April, respectively;

- the third unit, which is technically closely connected with the emergency fourth unit, but practically unaffected by the explosion, was stopped at 5 am on April 26;

Significant radioactive contamination of equipment and premises of the first and third units of the nuclear power plant was caused by the receipt of radioactive substances through the ventilation system, which continued to work for some time after the accident.

Separate sections of the computer room had significant levels of radiation, since its contamination occurred through the destroyed roof of the third block.

The government commission was tasked with carrying out decontamination and other works on the first and third blocks. The purpose of these works is to prepare the units for start-up and operation.

Decontamination was carried out using special solutions. Their composition was selected taking into account the washed material (plastic, steel, concrete, various coatings), the nature and level of contamination of the surfaces.

After decontamination, the levels of the? -ray decreased by 10 to 15 times. The radiation dose rate for rooms in the first and second units in June was 2-10 mR / h.

The final decontamination and stabilization of the radiation situation on the first and third blocks can be ensured only after the decontamination works have been completed at the nuclear power plant site and the emergency unit has been preserved.

5.5.

Monitoring and diagnostics of the status of the emergency block

Among the primary measurements, along with the assessment of the radiation situation at the station and around it, the reactor was monitored from the air. Helicopters carried out radiation measurements, surveys of the destroyed reactor building and its elements in infrared rays in order to measure the distribution of temperature fields, analyzed the chemical composition of the gases released from the reactor shaft and other measurements. After it was established that premises and equipment were preserved in the lower part of the reactor building, it became possible to conduct the first measurements and install emergency monitoring devices. First of all, neutron flow meters, y-radiation dose rate, temperature and heat flux were installed in a dehydrated bubbler pool. The thermometric equipment was duplicated. An assessment of the situation in the bubbler pool showed that there is no imminent danger of penetration of building structures. This created confidence in the safety of the work conditions for the creation of the lower protective plate.

The main efforts in the measurements at the initial stage were aimed at monitoring the possible transfer of fuel down. The solution of diagnostic problems was complicated by the following circumstances: the regular measurement system was completely disabled; The conclusions of possibly surviving sensors are not available to personnel; Information about the condition of the premises and the radiation situation in them is limited.

At the next stage it was necessary to determine the location of the fuel ejected from the reactor shaft and to estimate its temperature and the conditions of heat removal. To solve this problem, traditional methods of dosimetric reconnaissance were used, and also the surviving technological pipelines were opened for delivery of measuring probes. As a result of these studies, the distribution of fuel inside the building was basically determined. The temperature in the sub-reactor rooms since June did not exceed 45 ° C, which indicates a good heat dissipation.

5.6.

Decontamination of the nuclear power plant site

During the accident, radioactive materials were scattered throughout the territory of the station, hit the roof of the engine room, the roof of the third block, onto the metal pipe supports. The territory of the station, walls, roofs of buildings had significant pollution as a result of the settling of radioactive aerosols and radioactive dust. The contamination of the territory was uneven.

To reduce the spread of radioactive dust, the territory, the roof of the engine room building, the roadside roads were treated with various polymerizing solutions to fix the upper layers of the ground and exclude dusting.

In order to create conditions for comprehensive work on decontamination, the territory of the nuclear power plant was divided into separate zones. The decontamination in each zone is carried out in the following order:

- cleaning from the garbage and contaminated equipment;

- Decontamination of roofs and exterior surfaces of buildings;

- removal of soil with a thickness of 5-10 cm and its removal in containers in the solid waste storage of the fifth block;

- stacking if necessary concrete slabs on the ground or padding of clean ground;

- covering of slabs and non-concrete area with film-forming compounds.

As a result of the measures taken, it was possible to reduce the overall background of the radiation in the region of the first block to 20-30 mR / h. This residual background is mainly due to external sources (damaged block), which indicates a sufficient efficiency of decontamination of the territory and buildings.

5.7.

Long-term conservation of the fourth block

Conservation of the fourth unit should ensure a normal radiation situation in the surrounding area and in the airspace, as well as preventing the release of radioactivity into the environment.

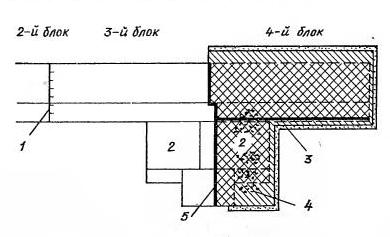

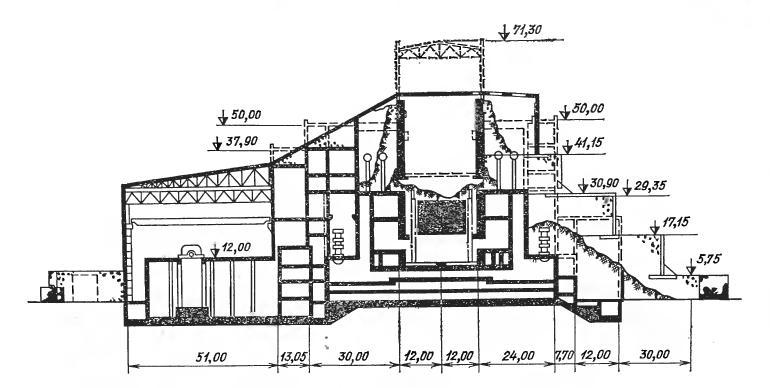

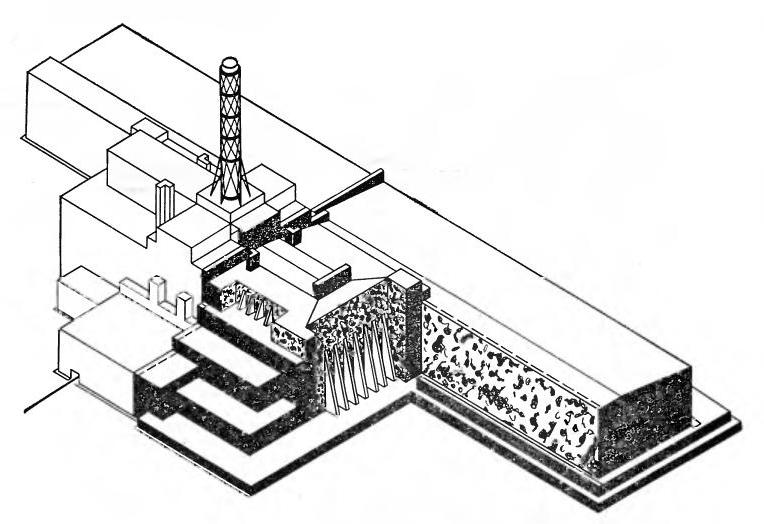

For the preservation of the block it is planned to erect the following building structures (Figures 5 - 7): external protective walls along the perimeter; Internal concrete separation walls in the machine room between the third and fourth blocks, in the "B" block and in the deaerator tunnel along the engine room and from the side of the balloon at the ECCS; Metal separation wall in the machine room between the second and third blocks; Protective overlapping above the machine room, as well as sealing the central hall and other reactor rooms and concreting the blockage in the balloon ECCS, the rooms of the northern MCP for the preservation of the obstruction and the creation of protection against radioactive radiation from the reactor block.

The thickness of protective concrete walls is 1 m or more, depending on the design and radiation situation.

Fig. 5. Scheme of burial of the 4th power unit of the Chernobyl nuclear power plant.

Horizontal section for one of the project variants:

1 - metal separation wall;

2 - reactor;

3 - external protective walls;

4 - zone of destruction of basic structures;

5 - concrete partition walls

Two variants are considered in the ventilation design:

- an open circuit with air purification on aerosol filters and release into the atmosphere through the existing vent center tube;

- a closed circuit with a heat exchanger located in the upper part of the ventilated volume, with a vacuum maintained in the volume of the building, provided by air sucking from the top of the volume and discharging it through the filters and the pipe into the atmosphere.

The following order of performance of the specified works is provided;

- removal of the surface layer of soil on local areas of the territory adjacent to the block, special equipment;

- Concreting of the territory with leveling of the surface, ensuring the movement of self-propelled cranes and other equipment;

- Decontamination of roofs and walls of the building (special polymeric pastes of different compositions are used in areas of high radioactive radiation);

- after cleaning and concreting the site, metal skeletons of protective walls are erected and their subsequent concreting;

- in process of erection of walls works on construction of the basic building designs providing full preservation of the fourth block are carried out.

5.8.

Decontamination of the 30-kilometer zone and the resumption of economic activities

Significant radioactive contamination of the territories adjacent to the nuclear power plant made it necessary to take an extraordinary decision regarding the establishment of controlled zones, evacuation of the population, prohibition or restrictions on the economic use of land,

It was decided to introduce three controlled zones: special, 10- and 30-kilometer. In them, strict dosimetric control of transport was organized, and decontamination points were deployed. At the boundaries of the zones, transplantation of working people from one vehicle to another is organized to reduce the transfer of radioactive substances.

Since June, construction of a complex of hydraulic structures for protection against pollution of underground and surface waters in the ChNPP region is underway, including:

- the anti-filtration wall in the ground along the incomplete perimeter of the industrial site of the nuclear power plant and the wells of dewatering;

- the drainage curtain of the cooling pond;

- the cut off drainage curtain of the right bank of Pripyat;

- an intercepting drainage curtain in the south-western sector of the nuclear power plant;

- drainage water treatment facilities.

By the present time, special agrotechnical and decontamination measures have been developed and are being implemented on the basis of the completed assessments of the situation with respect to soil and vegetation cover of the 30-kilometer zone, which enabled us to begin the return of contaminated land to the national economy. The complex of such measures includes: modification of traditional soil cultivation systems in the area, use of special formulations for dust suppression, changes in harvesting and processing methods, etc.

Fig. 6. Scheme of burial of the 4th power unit of the Chernobyl nuclear power plant.

Cross-section for one of the variants of the project.

Fig. 7. Scheme of burial of the 4th power unit of the Chernobyl nuclear power plant.

General view for one of the project options.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.