Paste GOI

GOI paste ( from GOI - State Optical Institute ) - grinding and polishing pastes based on chromium (III) oxide, used for grinding and polishing of steel alloys, including thermally strengthened, non-ferrous metals, hard plastics and polymers, glass (including Optical glass), ceramic materials and products from them.

GOI paste can be used for polishing products from a wide variety of materials. To date, several of its varieties are produced. For a particular material, you must select a certain type of paste. The polishing procedure itself should be done correctly. About how to use GOI paste, and talk.

Developers

GOI pastes were developed in 1931-1933. A group of Soviet scientists, employees of the State Optical Institute - IV Grebenshchikov, TN Krylova, VP Lavrov, SV Nesmelov.

History of Pasta

This polishing agent was developed in our country and for a long time - in the 30s of the XX century. The specialists of the State Optical Institute invented it. Hence the name of the paste (in the first letters) is GOI. For almost a hundred years, this tool has been used to polish steel, other metals, ceramics, plastics, stone and even glass. How to use GOI paste, our grandfathers also knew. Initially, it was made of chromium oxide and auxiliaries and had a green color. Today such a remedy can also be found in shops and on the market. However, the production of green paste is currently prohibited and discontinued. The fact is that chromium oxide is a poisonous carcinogen. Modern GOI pastes have a white or red color and are made of aluminum oxide. With the use of the second variety, polishing is faster. With the use of the same white paste, you can get a better and smoother surface.

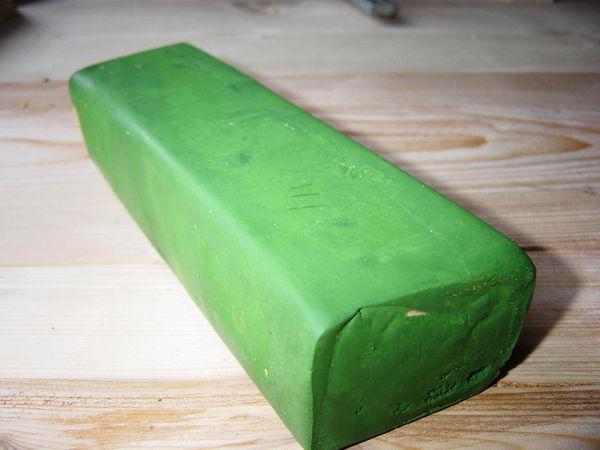

Appearance

GOI paste is a bar of light green or dark green color , consisting of an abrasive powder of chromium oxide, organic (fatty) binders and auxiliary substances (activating and intensifying additives). GOI pastes are produced both in the form of bars, and in the form of soft (felt) polishing circles already impregnated with paste. They are a mixture of chromium oxide (gives a green color, the shade of which depends on the percentage - 65-80%), as well as solvents and chemical reagents - kerosene, stearin, silica gel and others. There are 3 main grades of GOI paste: coarse, medium (in images) and thin (No. 1 and No. 2). Rough has a light green color, is most effective in removing the volume of material, gives a matte surface. Medium has a green color, gives a clean surface. Thin pastes are respectively dark green and black with a greenish tint of color, are used for fine grinding (lapping), impart a mirror shine.

Varieties of GOI pastes and their application

According to TU 6-18-36-85, four numbers of GOI paste are distinguished depending on the size of the abrasive particles:

- No. 1 (black paste with green tint, abrasive capacity 0.3-0.1 μm) for finishing polish, give the treated surface a mirror luster. Composition: 65-70 parts of trivalent chromium oxide, 1,8 - silica gel, 10 - stearin, 10 - split fat, 2 - kerosene, 0,2 - bicarbonate (drinking) soda;

- No. 2 (dark green paste, abrasive ability 7-1 microns) for fine polishing, gives the treated surface a mirror shine. Composition: 65-74 parts of trivalent chromium oxide, 1 - silica gel, 10 - stearin, 10 - split fat, 2 - kerosene, 2 - oleic acid, 0.2 - bicarbonate soda;

- No. 3 (pasta green, abrasive ability 17-8 microns) for medium grinding, gives a clean surface without strokes and is used to achieve even gloss polished surface. Composition: 70-80 parts of trivalent chromium oxide, 2 - silica gel, 10 - stearin, 10 - split fat, 2 - kerosene;

- No. 4 (light green paste, abrasive ability 40-18 microns) for rough grinding, gives a matte surface and is used to remove the smallest scratches left on the surface after grinding with abrasives. Ingredients: 75-85 parts of trivalent chromium oxide, 2 - silica gel, 10 - stearin, 5 - split fat, 2 - kerosene.

A green variety was produced both in solid bars and in the form of a more liquid paste-like mass (in boxes). The popularity of both types is determined not only by the high quality of polishing, but also by more than an affordable price.

The abrasive ability of the GOI paste is determined by the thickness of the metal removed from the steel plate 9 × 35 mm when it passes the path of 40 m along a cast iron plate 400 × 400 mm.

| No. | Type of paste | Paste Color | Abrasion ability, mkm |

|---|---|---|---|

| 4 | Rough | Light green | 40-18 |

| 3 | Mean | green | 17-8 |

| 2 | Mean | Dark green | 7-1 |

| 1 | Subtle | Black-and-green | 0.3-0.1 |

What you need to do before polishing

So, let's begin to understand how to use GOI paste. The fine particles that are in it, when rubbing the surface, remove a thin layer together with scratches and microcracks. Polishing is usually done with a soft cloth soaked in gasoline (it is possible from a lighter). On it put a small layer of paste and a little wipe it on an unnecessary piece of metal. This is necessary in order for the paste to break all too large pieces. If they remain, the surface can not be polished, but, on the contrary, scratched. The cloth must be really soft. You can take, for example, flannel. Sometimes the paste is applied to the polishing wheel. Directly on the surface of the processed product it can not be smeared. The product is preliminarily lightly smeared with liquid industrial oil ("spindle").

GOI paste: how to use

So, the cloth with the pasta is cooked. Now you can proceed directly to polishing. For this, the surface must be simply rubbed. Do not force the product too much. Otherwise, it may appear even more scratches. For the same reason, avoid too abrupt hand movements. Continue polishing until an absolutely smooth surface is obtained. From time to time, as necessary, the product should be applied a little "spindles".

How to polish GOI paste with a lot of deep defects? Usually, in such cases, the surface is pre-treated with option # 4. Then go to number 3. Finish processing number 2, and the final gloss induce tool No. 1.

After the operation is completed, you need to rinse the product in kerosene. The latter can be purchased at the pharmacy. If this can not be done, a polished object can be washed in running water. In some cases, the surface of the product after treatment, rinsing and drying is additionally coated with a lintel. This allows a significant slowdown of the oxidation process. The knives are polished using a bar with the skin stretched over it.

How to use GOI paste on glass and plastic

Very often this tool is used to bring in the "divine appearance" of cell phones. In this case, you will need to polish, firstly, the case itself, and secondly, the display glass. Since the plastic material is rather soft, a sparing paste of jars No.2 should be used for its processing. Otherwise, the case can be scratched even more. The answer to the question of how to use GOI's plastic paste is simple: just like when processing any other materials.

The glass is pre-polished with special rubber circles. Next, use the GOI paste itself. The procedure in this case is carried out in the same way, that is, using a rag. Oil and gasoline during the processing of telephones are not applied.

How to use GOI paste for cleaning silver products

As already mentioned, this tool, whether green, red or white, can be used to treat absolutely any metals. It concerns also silver. You can safely use GOI paste to lighten your spoons, cups and forks.

How to use GOI paste for silver cleaning? Before proceeding to polishing, the product should first be thoroughly cleaned with a toothbrush with the tooth powder applied on it.

Then in a glass of water, pour a little ammonia, adjust the soap and pour a little powder. All this must be thoroughly mixed until completely dissolved. Then the liquid is poured into some enamelled saucepan. After that, silver cutlery falls into it. Then pour the saucepan on a fire and bring the liquid to a boil. After that, the silver should be removed and rinsed in cold water. Next, you can proceed to its processing with GOI paste according to the method described above.

What not to polish

Next, let's see in what cases can not be applied GOI paste. How to use it, you now know. However, in no case should you use this tool to process gilded things. Otherwise, the upper valuable layer will be very quickly wiped off to the bottom metal. Steel (except knives) and nickel are processed usually not manually, but using a special machine. The metal watch is also polished with a cloth. However, they must first be disassembled and pulled out the mechanism. You can not start polishing too much scratched surfaces from option # 2 or 1. In this case, the defects will become even more noticeable. Sapphire glasses on the watch polish paste GOI will not succeed. She simply does not take them.

Where the remedy is used

With how to polish GOI paste, we sorted it out. Now let's see where exactly this tool is used. Apply GOI paste not only at home for polishing, silver, watches, dangerous blades and razors, etc., but also in production. In the latter case, it is used most often in galvanic plants for the processing of products from non-ferrous and ferrous metals. Polishing is performed using special polishing machines with felt wheels.

Foreign analogues

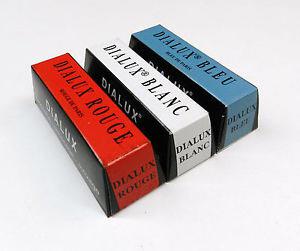

Today on sale it is possible to meet and import variants of similar pastes. A very popular option is the French Dialux. The latter differs in a firmer consistency and is worse applied to the skin of the bar when the knives are sharpened than the GOI paste. Dialux is considered more convenient to use. It is possible to polish the metal surfaces much faster and better. However, such pastes are more expensive. Varieties of Dialux are much larger than the types of GOI. This product is produced in blocks, packed in paper of different colors. On them you can navigate in terms of using Dialux for a particular metal.

Via fb.ru & wiki

Comments

Commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.