EkoMax water injection

- START

- EKOTYUNING-KIT

- SuperAquaCar

- Pulse

- UPG-2

- Activator Magnetic

- Fuel Activator

- Water injection (ECOMACS)

- HBO

- NanoVit

- V-Tech box

- EcoTop

- AirWing

- Anticoron AKOR

- Roher

- Ecotuning Oil

- Efficiency plus

- FFI MPG Supplements

- Zero filters (K & N)

- Lambda probe emulator

- Diesel particulate filter emitter

- Emulator of lambda probe and MAF

- Usefulness

- A PHOTO

- BUY & CONTACTS

The theme "Water injection into the engine" has been stirring the minds of mankind for more than a hundred years. It is patented by Mr. N. Otto, the father of the internal combustion engine, in the 19th century. Real realization it began to receive only in the last years of this century due to the development of microprocessor technology and the realization of a chemical algorithm for the behavior of water in an internal combustion engine.

Any internal combustion engine will convert only 25% of the heat energy into work, and accordingly the remaining 75% emits into the atmosphere with loud noise. Why is this part of the heat not offered to once again work on the problem of decomposition of water into chemical radicals for subsequent combustion, without a fundamental modification of the engine? When hydrogen (hydrogen) is burned with oxygen, water with a large amount of heat is produced, but to get hydrogen and oxygen from the water for subsequent combustion, you need to spend the same amount of heat. This explains the unshakable law of conservation of energy. Hence, the actions are zero !!!

The principle of the Ecomax system

From the tank, water enters the pump with a filter, then, under high pressure, into the injector nozzle. The nozzle is mounted on the intake manifold in such a way as to create a finely dispersed mixture of water and air. The pump and the injector receive control signals from the control unit, the brain of which is a micro computer. The micro computer calculates a portion of water individually for each stroke of the engine. The microcomputer operates with mathematical expressions, into which the values obtained from the sensors and values that are stored in the memory during system setup are substituted.

If the device is installed on the engine with injector fuel injection , the control unit receives and processes the control signals coming from the injectors dosing the fuel supply. The control unit also receives and processes signals from the engine temperature sensors and the presence of water in the reservoir. The control signals generated by the control unit are applied to the pump and the nozzle responsible for the water supply. And also, signals that affect the fuel supply are generated, which is the maximum system efficiency.

If the unit is mounted on a carburetor engine , the control unit processes the signals from the ignition coil, temperature sensor, throttle position sensor, water sensor. For the most efficient operation of the device together with the carburetor, it is necessary to adjust the carburetor (it is necessary to reduce the fuel supply). The control signals generated by the control unit are applied to the pump and the nozzle responsible for the water supply.

The proposed system of water injector is built on the basis of modern technologies using a microcomputer and is a complete device that is installed under the hood of the car.

Using a micro computer makes the water injector system easy to operate and configure. Also, the use of a micro computer allows you to accurately calculate and dose the required amount of water, which depends on the engine's operating modes, its temperature, crankshaft speed, throttle position, etc.

Water has an abnormally high specific heat, seven times the heat capacity of gasoline. She, entering the path of suction of crankcase gases of a carburetor or an injector and mixing with air, creates a water-emulsion mixture. The mixture, entering the collector, cools the air, thereby increasing its density. This leads to a rise in the filling factor of the cylinders and, as a consequence, to the increase in power.

The resulting mixture, moving further along the engine path, takes three and a half times more heat from the valves, piston surfaces, heads and cylinders, accumulating it in the subsequent work. Then, under the influence of a high temperature, which in some cases is excessive, water breaks up into free H-OH radicals involved in the chemical oxidation (combustion) of the fuel, increasing the completeness of combustion and, again, increasing the power. A side effect of the anomalous heat capacity of water is the fact of containing the flame propagation velocity, called "detonation" due to the active selection of energy in the places where micro-explosions occur. Due to chemical oxidation, not all hydrogen participates in combustion. Its excess is associated with carbon (carbon deposit), cleaning the surface of the cylinder-piston group and oil.

The suppression of the phenomenon of detonation allows the use of low-octane gasoline without increasing the flow and power loss in comparison with high-octane gasoline. This is due to the fact that the difference between the brands of gasoline is only in the presence of impurities that increase its detonation resistance.

It should be recalled that the principle of burning gasoline in cylinders is expressed by a simple school formula: CmHm+O<=>CO2+H2O+T°

It follows that the presence of water in the engine, which occurs as a result of burning fuel, does not cause corrosion. The use of alcohol mixtures does not improve the dynamics of the engine, but only contributes to the operation of the installation in the winter (lowers the freezing point of water).

This action of water is far from being limited, but this can not be stipulated, since it is the property of the manufacturer achieved by many years of testing.

To install the system on the car does not require any specialized car repair shops, with basic technical knowledge of the design of the car, any driver can set it by himself using the instruction for several hours. It can be used both in passenger cars and in freight and passenger transport.

Device Description

This device is an automated water supply system, that is, a water injection system with thermal control and the selection of the optimum water flow rate, depending on the engine speed. Using the "Ecomax" system on your car you get the following:

- Increase to 30% of the engine torque (especially noticeable in the city cycle)

- Fuel economy by 10-35% due to increased torque and vehicle power

- More efficient cooling of the engine in a hot period

- Softness and a significant decrease in engine noise, detonation and ignition dampening

- Increase the service interval of the car

- Increase of compression and engine life, reduction of shock loads in the work of the crank-piston group

- Complete disappearance of carbon deposits on pistons, valves, candles and reduction of CO emission by three times (achieved by optimization of combustion of fuel)

- The possibility of using gasoline with an octane rating is lower than that provided by the car manufacturer

- Ability to ride heavily depleted mixtures

The fuel consumption is reduced by increasing the engine power, which allows the driver to use higher gears. Ease of operation is achieved through full automation of all processes by the microcontroller system. Similar systems of this kind have been used for about 70 years in piston engines in aviation, which proves their relevance and reliability. And also in sports.

An example is the well-known AN-2 "Kukuruznik" aircraft, which, thanks to the use of the water injection system in the engine on the takeoff mode, increases power from 900 hp. Up to 1125 hp (instruction manual for the engine ASh-62).

Simple economic calculation

Take for example an a / m volume of 2L. The average annual mileage is 30000 km. The average flow rate is 10 l / 100 km. The average savings of 25% (real savings are 20-35%). Take the cost of 1 liter of gasoline or diesel for $ 1. And so: 3000 liters of gasoline at a cost of 3000 $ will be spent on 30,000 km. With the installation of the system, costs fall by 25% and amount to $ 2,250. And if you consider that you can switch to a lower-octane gasoline (taking its price for $ 0.9), then the cost per year will amount to $ 2025. And that savings per year is almost $ 1000.

-And if it's a car park? --- 20 machines = $ 20,000

- And if the consumption is not 10L, but 15L? Multiply this figure by K = 1.5 and get $ 30000

Etc., Arithmetic is simple, everyone can calculate their own version by mileage and expense.

Suitable for all types of cars and trucks on gasoline, gas and diesel fuel.

- 1. The maximum torque occurs at a ratio of air and fuel of 13.2: 1

- 2. Water Injection - to increase the power of the most effective in a ratio of 50/50 alcohols (or methanol) and water.

- 3. Water Injection requires the installation of an earlier ignition angle (2o - 3o) in comparison with the normal engine operation. In injection engines, the angle of ignition is set automatically.

- 4. Excessive ignition timing will cause power drop and overheating.

- 5. The quality of spraying an aqueous mixture - is directly related to the effectiveness of the system. Smaller droplets cool the combustion chamber better and more evenly.

- 6. The introduction of water allows working at higher pressures without detonation. A higher pressure will increase the torque.

- 7. Cooling of potential hot spots in the combustion chamber eliminates ignition ignition, which is the most destructive form of uncontrolled combustion in the combustion chamber.

Influence of detonation on the internal combustion engine

Water injection is a technology that is as old as the car itself. Water injection can suppress detonation even with increasing pressure in the cylinder and reducing the octane number of fuel.

This method has one more advantage - availability and cheapness of water in virtually any place!

Influence of detonation on engine operation and its elimination

The normal process of combustion of the fuel charge in the cylinder is as follows. The piston is approaching the top dead center, the working mixture (gasoline vapor, air and some residual combustion products) is compressed. At the right time, a spark jumps between the candle electrodes, and here a primary ignition spot with a volume of several cubic millimeters is formed, the energy of which is composed of the energy of the spark and the energy of the fuel burned in this zone.

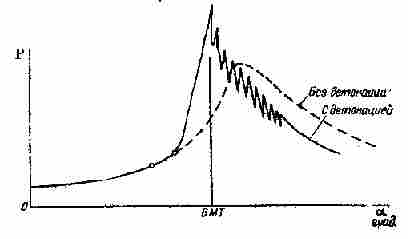

Detonation occurs when the fuel-air mixture in the cylinder instead of progressive controlled combustion spontaneously explodes. This causes a sharp increase in pressure and temperature in the cylinder, which can damage the pistons, rings and even the head. Detonation can sometimes be heard as a foreign metal knock coming from the engine. Sometimes, detonation does not impart itself by extraneous sounds, but it manifests itself in a decrease in engine power.

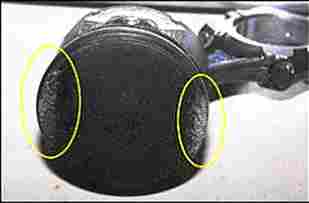

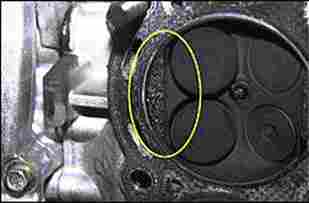

Damaged piston and head

Some influence on the occurrence of detonation is deposited in the combustion chamber

The fact is that deposits on the walls, first, worsen the heat transfer, and secondly - increase the actual compression ratio. In other words, they create the conditions for disrupting the normal combustion process. Moreover, the deposit can have a known catalytic effect and cause a self-ignition of the working mixture. And further. In the transient modes of engine operation, the deposit sometimes begins to loosen and separate; Then the particles, which have lost a close contact with the wall, easily overheat and can provoke a firing ignition. It also happens that the scales of the deposit break away, but they do not leave the combustion chamber for a while, but remain in it. They easily heat up and ignite the working mixture at the most uncertain moment, even at the inlet. So are born; "Wild" thuds, which are not amenable to any logic and classification.

Combustion with detonation

Water injection can prevent the appearance of detonation and operates in three directions. First, when water is injected into the intake manifold system to the cylinder cover, small droplets absorb heat from the air. The cooled air has a high density, thereby increasing the amount of oxygen that enters the cylinder. Water has a high heat capacity (it can absorb a lot of energy with a slight increase in temperature). Then, small droplets evaporate in the cylinder and cool it, while the resulting vapor increases the pressure in the cylinder. This acts as an anti-detonant and also cleans the cavity of the combustion chamber from carbon deposits, thereby eliminating unwanted "hot" points.

A bit of history

By and large, any conversation on the topic of innovations for a car can begin with the fact that most of the technologies used today were known already a hundred years ago (this is supercharging, nitrogen injection and much more), and eighty percent of the processes occurring in the cylinder , Have not been studied to the end to this day.

As already noted, most of the technologies are far from new, and the first experiments with water injection into the engine began in the 1930s (the first patent for such a system was issued in the USSR in 1934!). In those days, no one had ever thought about using this technology to obtain additional power or save fuel - experiments were aimed at avoiding the phenomenon of detonation (explosion of a fuel-air mixture in a cylinder, instead of progressive combustion). Approximately at the same time in the United States, water injection studies are conducted, the purpose of which is to study the ongoing processes in the engine and the use of water injection in aircraft engines.

So would the injection of water be forgotten, if not for the plight of the national economy in the postwar years. The system was re-applied, allowing the use of gasoline with a lower octane rating without compromising engine power.

Although we say "water injection", in fact pure old good H2O allows, to a greater extent, to reduce detonation (plus, acting as an antioxidant, prevents the deposition of carbon compounds). And now we will explain why.

Water has a very high heat capacity, which helps to reduce the temperature of incoming air, and, as we know from the school course of physics, to compress the colder air requires less energy. Evaporating in the combustion chamber, the water increases in volume, which means that the pressure inside the cylinder also increases, which means that there is an increase in power.

It will be superfluous to recall that no system can be fully used without proper engine tuning, either a depletion of the mixture, or an increase in pressure, or an earlier ignition. "Honed" aircraft engines of the times "Luftwaffe" had devices for automatically depleting the mixture during the injection of water. In our case, the microcomputer of the Ecomax device is automatically tuned! , Which calculates all the necessary parameters.

And the most "tasty" - properly installed and configured system is absolutely safe for the engine! Even more - as has already been said, water prevents the deposition of carbon compounds! In a word, when all the iron is rotten, the engine will still be given to your grandchildren.

Comments

Commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.