home  Management Management  The organization of production - AS Kurochkin The organization of production - AS Kurochkin |

The organization of production - Kurochkin AS

The organization of the production process partionnogo

On the duration of the production cycle significantly affect the size of batches of parts and the type of movement of parts (objects of labor) in the course of their treatment.

Party refers to the number of parts are continuously processed at each operation of the production cycle with a single-consuming set-up times. Work parties are only available in serial and mass production.

SUMMARY batch production is that the manufacturing process of one part (or products) to each workstation is not constant, and in order to interleave with the manufacture of the same workplace other parts. Consequently, it is related to readjustment of the equipment. And the more the size of the production run in batches, the longer the interval between changeovers and fewer interruptions due to equipment setups. However, the volume of work in progress, which requires space, packaging, transport and working capital increases. Therefore, the optimal size of the party must provide at least the cost of preparatory and concluding works and losses from sedimentation of working capital in production. In determining the size of the party must take into account certain rules.

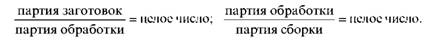

1. For the same product lot size in adjacent stages of production should be either equal or multiples, and party products at a later stage can not be less than the party in the previous step, ie. E.

2. Consignment size n is calculated according to the formula

where t pz - set-up time per game; t units - single-part time; R - coefficient of allowable losses for changeovers (depending on the complexity of the equipment R ranges from 0.03 to 0.1).

The resulting batch size is adjusted for the replacement of equipment productivity, tool life and tooling, rapid manufacturing schedules, transport facilities, container capacity and so on. N.

The duration of the production cycle in mass production depends on the chosen type of movement for the party transactions: serial, parallel and parallel-to-serial.

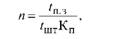

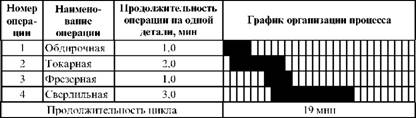

Serial kind of movement parts party is characterized by the fact that each subsequent operation starts only after processing all the details on the previous operation. The principle of such an arrangement is shown in the Table. 4.

Table 4

SERIAL TYPE OF PRODUCTION PROCESS (Party - 4 parts)

Sequential view of the production process does not exclude the concurrent (parallel) manufacture the same parts on multiple machines doubles; Highest efficiency is achieved in terms of individual and small batch production.

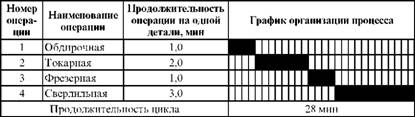

Parallel view of the production process is characterized by the fact that each piece goes to a subsequent operation immediately after the completion of the previous one. As a result, parts constituting one batch simultaneously on the different (at all) processing operations. This type of production (Table. 5) is considerably shorter than the sequential, but unequal in duration successive operations of their combination results in downtime (on shorter operations). It is most effective in large-scale and mass-line production, where all operations for the duration of the same or multiples of each other.

Table 5

PARALLEL VIEW OF THE PRODUCTION PROCESS (Party - 4 parts)

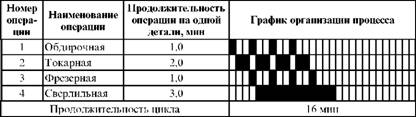

When serial to parallel form of organization of the production process (tab. 6) parts come from one operation to another small (transport) parties, but so that the production process is carried out continuously, ie. E., Without downtime. This makes it possible to combine the most complete loading jobs with the least duration of the production process. It used this type of production with the release of the same name products in areas with uneven power equipment and partial synchronization operations.

Table 6

Serializer VIEW OF THE PRODUCTION PROCESS (Party - 4 parts)

The duration of the production cycle, as well as the timing needed to organize the timely launch materials, blanks and semi-finished products at all stages of the production process, are calculated according to certain formulas.

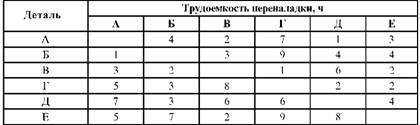

Since the organization of serial production is associated with frequent changeovers (especially in stamping, kuznech-but-press, mechanical and foundries, with injection molding machine), it is necessary to establish the optimal starting order details to reduce the changeover time. In practice, this is performed as follows. For each piece of equipment fixed six or seven types of parts. With valuations determine the complexity of changeovers from one part to another, and the data are entered into the table. 7.

Table 7

OPTIMAL CHOICE ORDER STARTING PARTS To reduce the time changeovers

Example. When changeover equipment items A to part D (first row of Table 7). Complexity of 7 hours, with parts in the workpiece E -.. 2 hours, etc. In each column and each row are smallest number and comprise two or three options changeovers. will be the optimal order of readjustment, in which the amount of time (labor input) will be lower. For example:.. A-D-E-G-B-B-A, ie 1 + 4 + 2 + 1 + 3 + 1 = 12. For any other order the complexity of changeovers significantly increased. For example, B-A-B-D-E-D-B, ie, 1 + 2 + 1 + 2 + 8 + 3 = 17...

Comments

Commenting, keep in mind that the content and the tone of your messages can hurt the feelings of real people, show respect and tolerance to his interlocutors, even if you do not share their opinion, your behavior in terms of freedom of speech and anonymity offered by the Internet, is changing not only virtual, but real world. All comments are hidden from the index, spam control.