Generator of water from the air

| Generator of water from the air |

|

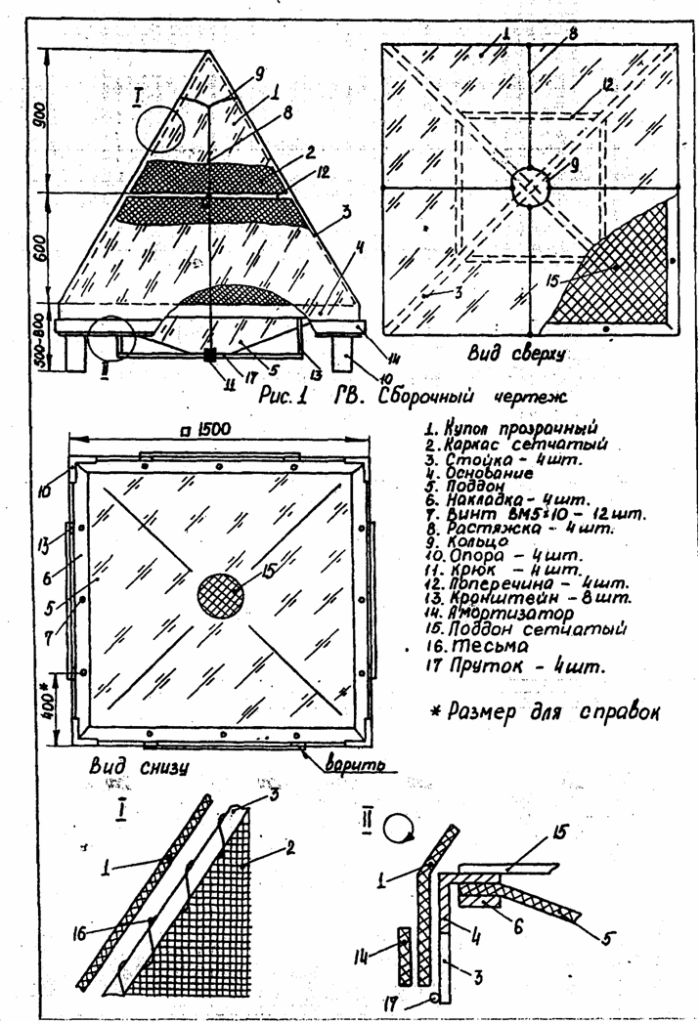

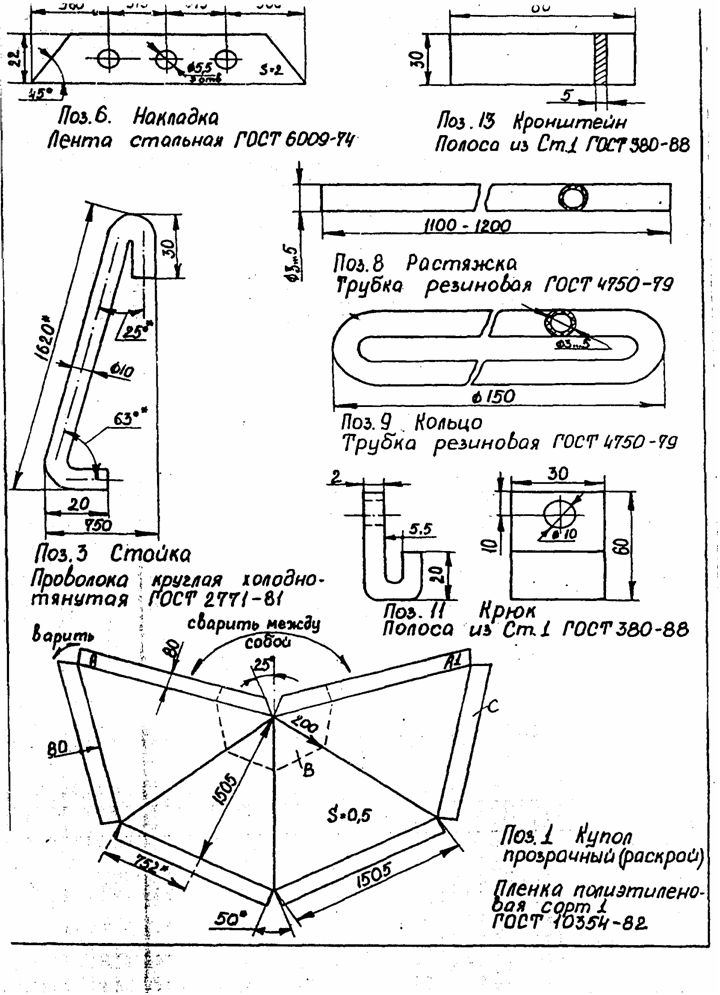

The water generator (hereinafter HS) is designed to concentrate and discharge water from the surrounding air. Operating principle. GV is a pyramidal frame with a moisture absorbing filler. The pyramidal skeleton is formed by four posts pos. 3, welded to the base of pos. 4, made of a metal corner. In the space between the corners of the base is welded a metal mesh pos. 15; Bottom to the base with the overlays pos. 6 is fastened the polyethylene tray pos. 5 with a hole in the middle. The inner space of the mesh frame is densely (but without deformation of the walls) filled with a moisture-absorbing material. Outside, a transparent dome poses on the pyramidal frame. I, which is fixed by means of four extensions pos. 8 and shock absorber on. 14. GW has two working cycles: the absorption of moisture from the air filler; Evaporation of moisture from the filler followed by its condensation on the walls of the dome. With sunset, the transparent dome is lifted to provide air access to the filler; The filler absorbs moisture all night. In the morning, the dome is lowered and sealed by a shock absorber; The sun evaporates the moisture from the filler, the steam is collected in the upper part of the pyramid, condensate flows down the walls of the dome onto the pallet and fills the filled container through the hole in it. Manufacturing of HS. Preparations for the production of HS are started from the collection of the filler. As a filler, scraps of newsprint are used; Paper from newspapers should be taken free from typographical font to avoid clogging of the resulting water with lead compounds. The work on the collection of paper will take a lot of time, and during this time the remaining elements of the GW are manufactured. The base is welded from metal corners with the dimensions of the shelves 35x35 mm, from below are welded to the four supports pos. 10 of the same corners and eight brackets pos. 13. Brackets are connected with each other by steel rods pos. 17 length of 930 mm. Diameter of 10 mm. From the top on the shelves of the corners welded metal mesh with a size of cells 15x15 mm. The diameter of the grid wire is 1.5-2 mm. From the steel strip are cut four pads pos. 6. The holes in the plates are drilled holes 4.5 mm in diameter at the corners of the base and threaded screws for screws BM 5; Then the base is placed in place, determined for HS in the garden plot, garden, etc. The place should be chosen so that the GW is not obscured by trees and buildings. After choosing the location of the support of the base is fixed in the ground with cement mortar. It is permissible to weld to the supports a support pentak with a diameter of 100 mm from a steel sheet 2 mm thick. After that, four corners are welded to the corners of the square of the base in such a way, the posts turned out to be 30 mm long and found themselves in the center of the base at a height of approximately. The material of the cross bars is the same as that of the pillars. Then, from a polyethylene film 1 mm thick, the pallet pos. 5; The edges of the pallet, which will be under the lining, "turn to strengthen the attachment point.In the center of the tray, cut a round hole with a diameter of 70 mm - for drainage of water.The edges of the holes can also be strengthened by welding an additional lining of polyethylene. Further, fixation is made on the racks of the mesh frame, which is a fine-meshed fishing net with a cell size of 15x15 mm. The network is tied to the racks and edges of the pallet from the metal mesh with the help of cotton tape. So that the network was ryi about stretched between the racks. It is also desirable to tie the net to the crossbeams, dividing the inner volume of the pyramid into two compartments. Before tying the net to the last rack, the compartments (starting from the top) of the resulting mesh frame are densely filled with crumpled newsprint scraps. Filling should be done so that there is no free space inside the pyramid and the protrusion of the mesh walls was minimal. Then they start to make a transparent dome. It is made of polyethylene film, which is cut according to the drawing pos. 1 and is welded by a soldering iron along the planes A, A1. The seam should be made without overheating, so that the polyethylene does not become brittle at the welding site. To prevent violation of the integrity of the dome in the top of the pyramid, it is covered with a kind of polyethylene "cap" - fragment B according to the drawing pos. 1. Then, after putting on the fragment B on the pyramid, carefully put on the skeleton dome. Having straightened the dome, weld the edges of the planes C: one obtains a kind of "shape." A ring of 9 is made from the rubber tube, which is put on the pyramid, and four braces with hooks poses are fastened to the ring.The bottom of the transparent dome ("skirt") is dense Shock absorber o ring made of rubber tape 5000 mm long, 50 mm wide made of rubber bandage If there is no polyethylene necessary area for the dome, it is welded from several fragments of polyethylene. For welding polyethylene it is recommended to use a soldering iron with a power of 40-65 W, a groove is made in the sting of xoTopotp, a metal disc with a thickness of 3-5 mm is fixed in the groove on the axis. HV operation. With the sunset, the transparent dome is turned up to the level of the cross bars and fixed in this position by stretching, putting the hooks on the bars pos. 17. Overnight paper absorbs moisture and, in the morning, the dome is lowered, fixing its lower edge on the base of the shock absorber. During the day the sun will heat up the pyramid, the moisture from the paper will evaporate, the steam will condense on the walls as it cools down into the water that flows down. Water is collected by substituting a container for the opening in a polyethylene tray. With the sunset, the cycle is repeated. Paper in HS is recommended to change every season, for the winter the dome should be stored indoors. It is also recommended to change the dome after the loss of transparency of its walls. |

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.