home

Management Management

Organization of production - Kurochkin A.S. Organization of production - Kurochkin A.S.

|

Organization of production - Kurochkin A.S.

Methods of organization of production

The type of production determines the method of its organization. The method of organization of production is a set of methods and methods for realizing the production process. Its main characteristics include:

• the relationship between the sequence of operations of the technological process and the order of location of equipment;

• the degree of continuity of the production process. There are three principal methods of organization of production: incoherent (operating), continuous, automated.

The non-flow (inoperative) method of production organization is used mainly in single and small-scale production. It is characterized by the following main features:

• The production equipment is grouped according to the performance of the work (process), as shown in Fig. 10. So, in a mechanical shop, all the lathes are grouped in one section (a section of lathes), all drilling machines - on the other, and so on;

• technological equipment is mostly universal. At the same time for the processing of particularly complex parts, special machines are used, for example, planing machines, carousel (a section of special machines);

Fig. 10. Typical inaccurate (inoperative) production planning

• between groups of process equipment, as a rule, intermediate warehouses and workplaces of controllers of the department of technical control (OTC) are located;

• Parts in the manufacturing process are moved from one operation to another by complex routes, therefore in the technological process there are long breaks due to waiting in interim warehouses and at workplaces of OTK controllers. This is due to the fact that each worker receives a part for performing a subsequent operation not from the previous operation, but from an intermediate warehouse or from a QC inspector.

When developing a technological route for the manufacture of a part or assembly using a non-exact method, it is most difficult to minimize transport operations. In addition, such a route is complex in organizational terms and does not fully comply with the principles of rational organization of the production process.

The flow method of production organization is used for mass, large-scale and medium-series production. It is characterized by the fact that the object of labor in the process of processing follows the established shortest route without expectations at intermediate warehouses and at workplaces of OTK inspectors. This is the most perfect method of organizing production for clarity and completeness.

Characteristic features of the on-line method of production organization include:

• Separation of the production process into separate operations and their long-term fixation for a certain workplace;

• specialization of each workplace in the performance of a specific operation;

• coordination and rhythmic execution of all operations in all workplaces on the basis of a single calculated cycle (rhythm) of the production line;

• placement of workplaces in strict accordance with the sequence of the technological process;

• moving objects of labor from one workplace to another with a minimum break and using special transport devices.

A typical flow plan for placing workplaces is shown in Fig. 11. Such a method is based on the principles of rational organization of production - directness, continuity and rhythm.

Fig. 11. Typical Production Flow Planning

The main organizing element of the line production is the production line. It is a collection of specialized jobs, located in accordance with the technological process.

Depending on the level of specialization of production, the volume and nature of the products manufactured, the technology and technology used, the production lines are classified according to certain characteristics.

According to the nomenclature of processed products, we distinguish such constant-flow lines:

• one-color (typical for mass production, after which processing or assembly of one product name is fixed for a long time);

• multi-disciplinary (typical for batch production, they can handle several types of products that are similar in design and technology).

The following lines are distinguished by the degree of continuity of production:

• continuous-flow (this is the most modern form of on-line production, where strict rhythmicity and the shortest duration of the production cycle are ensured.) Widely used in the auto industry, watchmaking industry, etc.);

• interrupted-streamed (they do not provide a clear synchronization of operations at workplaces, they are mainly used in a serial production type, when labor-intensive parts processing processes are performed on a variety of equipment).

According to the method of maintaining the tact, lines are distinguished:

• with a regulated clock (on them the products are moved from one workstation to another through precisely fixed time, are characteristic for continuous-flow lines);

• with a free tact (on them the products move to the next jobs as they are ready for reception).

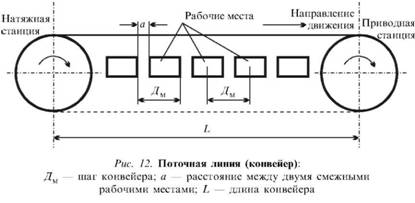

In the production line, the following special vehicles are used (figure 12):

• non-drive - roller tables, gutters, rajids, trolleys, etc .;

• Drive:

- Hoisting and transport mechanisms - bridge, cranes, crane beams, forklifts, electric forklifts, etc .;

- conveyors, i.e. drive vehicles, which not only move objects of labor from one operation to another, but also regulate the stroke of the flow.

By constructive features, conveyors are distinguished:

• belt;

• Chain - plate, scraper, hanging, etc.

Depending on the nature of the movement, the conveyors are with continuous and discontinuous (pulsating) motion.

On conveyors with continuous movement, operations are performed simultaneously with the movement of objects of labor, on conveyors with pulsating motion - during the period of its immobility.

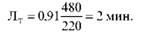

In conclusion, we note the main quantitative parameters of line production. One of them is the calculated cycle of the production line (Lt), min:

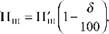

Where Фр - fund of working time for the accepted period, mines; Пш - the program for the same period taking into account the minimum admissible marriage, pcs. If the marriage exceeds 1%, then the program, pieces,

Where Пш - the program without marriage, pcs; 8- allowable marriage,%.

When calculating the cycle for continuous-flow lines with a regulated rhythm of work, the scheduled breaks in work for the rest of workers and organizational and technical services established for such lines are taken into account. An approximate break schedule for an eight-hour working day is given in Table. 10. Thus, in the formula for calculating the measure, enter the utilization factor of working time (k). In this case, the formula takes the following form:

Table 10

EXAMPLE SCHEDULE OF CHANGING REGULATED BREAKS ON STREATING-CONVEYOR LINES FOR A CHANGE

Example. If during the shift the conveyor has two breaks for 20 minutes, then, k = 440: 480 = 0.91. Then with n = 220 pieces. In-line beat

The working length of the conveyor is determined based on the distance between the centers of adjacent work stations (the conveyor step) and the total number of work places on the line. In a general view, step

Where V is the conveyor speed, m / min.

The speed of the conveyor is adopted as follows: when working without removing the objects from the tape - 0.2-0.8 m / min, with the removal of the object from the tape (conveyors of discontinuous action) - up to 2.5 m / min.

If the duration of one operation does not exceed 3 minutes, it is advisable to apply a continuous-flow type of production, if it exceeds this time - interrupted-continuous.

In the organization of any on-line production, the normal level of stocking is of particular importance. Without sufficient saturation of all the phases of the production process, systematic and uninterrupted execution of the program can not be ensured. By location, there are different types of intralinear (cyclic) and inter-line (inter-shop), or warehouse. First count their number for each species, then add up and the result is taken as a basis for calculating program tasks.

When streamlining the production process, you must follow certain rules:

• monitor the size of the stockpiles, maintain the calculated cycle, and provide transport parts of the parts on the conveyor in a timely manner;

• observe regulated rest breaks;

• to seek the development of workers in related professions and operations on the line;

• periodically move workers along line operations.

Realizing the advantages of a streamlined method for organizing the production process

With the on-line method of organizing production, the basic principles of the rational organization of the production process are realized most fully. At the same time, in all other cases, the virtues of certain principles are achieved at the expense of others.

The principle of specialization is realized by fixing certain operations for each workplace; The principle of proportionality - through the synchronization of operations and the organization of parallel workplaces; The principle of parallelism is due to the parallel movement of products, when different operations are performed simultaneously on different parts of the product; The rhythm of output of products - at the expense of the production line, when the products come off after a certain period of time; Principle of directness - by placing workplaces in accordance with the technological process; Continuity of processing of products - due to the parallel movement of products, i.e. without laying down.

The specialization of equipment and technological equipment, the rhythmic frequency of the processes, ensure a sharp increase in labor productivity, which, in turn, contributes to an increase in the volume of output from a unit of equipment and production area, i.e., an increase in the total output.

Thanks to the introduction of in-line production, the production is cheaper due to a reduction in its prime cost. It should also be noted that when using the on-line method of production organization, the technical equipment of the processing and control processes increases, the responsibility of each performer for the assigned work increases, as a result of which the quality of the products increases and the amount of rejection decreases.

For the organization of the on-line method of the production process, it is necessary to have certain technical and organizational conditions: design, technological, organizational and material.

Design conditions - special requirements for maintaining the uniformity of structures, the interchangeability of structural elements, standardization and normalization of components and parts of products, dismemberment of the product to units and assemblies that can be assembled before the general assembly. If products planned to be transferred to production methods of manufacturing some of these requirements are not sustained, then the products are reconstructed.

Technological conditions - careful testing of the technological process with the maximum separation of it into individual operations, the use of high-performance equipment and rigging, mechanization and automation of control operations, adjusting and testing processes. Specific requirement - every operation, rigging should help to solve not only technological tasks, but also provide such a duration of operations, so as to maintain the tact of the production line.

Organizational conditions - a sufficient volume of production, which provides a full load of workplaces on the production line (especially parallel, organized in order to eliminate equipment downtime in parallel movement of products), a clear specialization of workplaces, the optimal choice of their service system, determining the operating mode of the production line, regulated Breaks.

Material conditions - a clear organization of uninterrupted material and technical supply, systematic and rhythmic "feeding" of the production line, providing each workplace with the necessary stock of equipment sets.

Experience shows that if these conditions are met, it is possible to introduce streamlined methods for organizing the production process, not only in mass and large-scale production, but also in small-scale production.

Automated production is a production process in which all or the vast majority of operations requiring physical effort are performed by machines without direct human participation. Workers perform only the functions of adjustment and control.

Automation of the production process is achieved through the use of machine-machine systems, which are a combination of a variety of equipment and other technical devices located in a technological sequence and combined means of transportation, control and management to perform partial production processes.

There are four main areas of automation. The first direction is the introduction of semi-automatic and automatic machines. The highest achievement of this direction is the machine with numerical program control (CNC). They work according to a given program without the direct involvement of a person and produce various parts or perform certain production operations. Using CNC machines allows you to increase productivity at each workplace by 3-4 times.

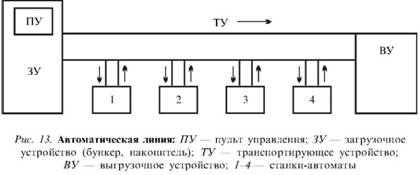

The second direction is the creation of complex machines with the automation of all the links in the production process. A typical example of such machine systems are automatic lines (AL). They are a combination of a system of automatic machines with automatic mechanisms and devices for transportation, control, accumulation of stockpiles, waste disposal, and management (see Figure 13).

The automatic rotor lines (ARL) are much more effective, which are a kind of automatic lines equipped with special equipment based on rotary machines and special transporting devices.

The effectiveness of AL application is significantly increased as a result of their creation on the basis of multipurpose machines, i.e., the creation of so-called flexible automatic lines. Such lines with a programmable device are equipped with CNC, which makes them cost-effective not only in mass and large-scale production, but also in small-scale production.

The third direction is the design and production of industrial robots. In the production process, they perform functions similar to the human hand, and because of this replace the human movement. The introduction of robots into production allows creating multi-purpose technological systems capable of performing universal manual operations for a person in all their diversity. Such systems are usually called robotic complexes (RTK). In the process of performing operations, robots are able to solve complex logical problems, which until recently were a monopoly of the human mind.

The indicator of the effectiveness of the functioning of the RTK is the most complete loading of the equipment included in its structure. With the introduction of robots into production, the entire organization of the technological process radically changes, many negative factors are eliminated, caused by man's fatigue, dulling of his attention, violation of coordination of movements. As a result, manual operations are eliminated, labor productivity and product quality sharply increase.

The fourth direction is the development of computerization and the flexibility of production and technology. By the flexibility of production is understood its ability to quickly and at minimum costs on the same equipment to move to the release of new products. The basis of flexible production systems (FMS) is a flexible production module (GPM) - an easily-operated and autonomously functioning unit of automated equipment with CNC where the loading of blanks and the removal of processed parts are carried out with the help of industrial robots (manipulators), the tool is replaced and chips are removed, Liquid, monitoring and fault diagnosis. Flexible production modules not only quickly adapt to the manufacture and assembly of new parts or components, but also easily integrated into flexible production complexes, lines and even plots.

Flexible production systems are economically highly efficient. So, in the case of the application of GPS machining of hull details on machine tools such as "machining center", labor productivity rises by 2-2.5 times, capital productivity increases by 15-20%. Благодаря почти двукратному сокращению продолжительности изготовления деталей экономится до 25-30 % оборотных средств. При этом улучшается культура производства, создаются условия для ритмичной работы производственных подразделений, повышается качество выпускаемой продукции.

Гибкая производственная система, являясь высшей формой автоматизации, включает в себя в различных сочетаниях оборудование с ЧПУ, РТК, ГПМ и различные системы обеспечения их функционирования. Как показывает отечественная практика, применение ГПС целесообразно тогда, когда годовой объем выпуска каждого из 5-10 типоразмеров (наименований) деталей составляет 50-2000 шт. Гибкие модули эффективны при годовом объеме выпуска любого из 30-80 типоразмеров деталей, равном 20-500 шт.

Comments

When commenting on, remember that the content and tone of your message can hurt the feelings of real people, show respect and tolerance to your interlocutors even if you do not share their opinion, your behavior in the conditions of freedom of expression and anonymity provided by the Internet, changes Not only virtual, but also the real world. All comments are hidden from the index, spam is controlled.